On any job site, the strength of a concrete pour is a critical piece of information. A concrete cylinder test or concrete break test has been the pillar for compression strength testing in the construction industry for more than 180 years (Concrete Network).

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

How do Third-Party Labs Perform a Concrete Cylinder Test?

- Standard-Cured Cylinders

- Field-Cured Cylinders

As the name suggests, field-cured cylinders are subject to the same temperature and relative humidity levels that the completed structure will experience in its environment. Unlike standard-cured cylinders, field-cured specimens are kept right beside the concrete slabs on site. They are predominantly used for determining whether a structure is ready for critical operations like removing formwork, tensioning, and road openings.

In standard or lab curing, concrete test cylinders are sent to the lab and subjected to standard temperatures and humidity conditions —23.0 ± 2°C and relative humidity that’s greater than 95% as outlined in the project’s specifications. They are generally used for quality control and standard acceptance purposes.

Lab Steps

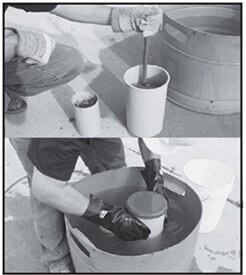

When the specimen (e.g. drilled cores and molded cylinders) is ready to be tested in the lab, the technician follows these steps:

- Examine the concrete cylinders to ensure that there are no defects

- Measure and weigh the cylinders and prepare the samples by grinding or capping the ends

- Place the samples in the hydraulic compression testing machine and carefully align them with the loading axis

- Allow the machine to compress the sample until it splinters or breaks

- Record the compressive strength and type of failure

The cylinders are then tested usually 3 days, 7 days, and 28 days after field installation to determine the concrete’s compressive strength. Sometimes, tests will also be carried out at 24 hours, 14 days, or 56 days depending on the project specifications.

Want to learn more about what concrete curing is? Read this blog

The Pros of Using Third-Party Concrete Testing Labs

“ASTM C39: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens” has been in existence for many decades. It outlines specific rules and conditions to ensure that labs properly test concrete samples. As the construction industry’s most utilized concrete compression strength testing method, engineers, project managers, and contractors can trust that it will provide accurate measurements (most of the time).

As long as the procedure adheres to the standard, and test reports are accurate, it’s nearly impossible to falsify the strength of the concrete with this method. For example, fly ash can be added to concrete to improve its strength and durability. However, to cut corners in some cases, material providers replace fly ash with fillers in their concrete mix. In this scenario, the strength of the concrete may meet the industry standard after 24 hours. Yet, thanks to the concrete cylinder test, labs will discover that the strength diminishes to well below the minimum accepted strength after only a few weeks. This gives the construction company the knowledge they need to avoid building a weak structure made of sub-par concrete.

Reputation and Costs

Thanks to the method’s highly established reputation, companies also understand that they don’t have to spend too much of their time or financial resources to find qualified labs and technicians to carry out break tests.

Furthermore, concrete test cylinder tests are quite cheap to execute as the molds are made of plastic. But some are made of metal which means they can be reused. The test itself can cost anywhere from $70 to $250 to break a set of three concrete test cylinders.

Why the Cons of Third-Party Concrete Testing Labs Can Impact Your Project

Despite the benefits of using third-party labs for concrete cylinder testing, this method isn’t completely foolproof. There’s a lot of room for improvement when it comes to optimizing the use of resources. This can include: minimizing costs, increasing accuracy, and reducing the time it takes to measure concrete strength.

As everyone in the construction industry knows and has accepted, completing a concrete cylinder test from start to finish is a time-consuming process. Once concrete is poured the cylinders are made by a technician and placed in an adequate curing environment. For standard-cured specimens, they must sit for 8-24 hours before they can be collected and transported to the lab for a break test to be completed.

Test results of fresh concrete are known immediately, at least by the technician. Nonetheless, results for compressive or other hardened properties like flexural strength are not normally available until formal test reports are released. Needless to say, break tests don’t allow for real-time results.

Human Errors are Always Possible

The concrete cylinder testing method isn’t an inefficient method as a whole. However, there has been a considerable amount of “bad” or low breaks recorded. This could be attributed to technicians failing to follow the standard’s specifications rather than the standard itself. For example, if the cylinders aren’t cured in the right way, this can result in a low break. Unfortunately, low breaks caused by human error aren’t the only concern that companies have regarding inaccurate results. There have been cases of labs manipulating and falsifying results. Even for major buildings that see a lot of traffic on a daily basis. Furthermore, there has been documentation of the wrong concrete mix being delivered to the jobsite. This results in even more delays if it’s caught in time.

Case Study: ARW Concrete Contracting

ARW Concrete Contracting experienced a similar issue when they discovered that their ready-mix producer added water to their mix. Read about their experience here.

While individual break tests are inexpensive, these costs add up over time, especially on large construction projects. The costs incurred due to errors made on the part of the field technician or lab also need to be considered. For example, if the field technician fails to properly consolidate the concrete cylinder by rodding the sample or using a vibration machine, it can result in a bad sample. Mistakes can also occur in the lab and during transportation. A lab technician could accidentally allow the perpendicularity of a cylinder’s axis to deviate by more than half a degree, for example. Or, cylinders may not be stored properly during transportation and may cause micro-cracking. This would reduce the overall strength of the cylinder during testing and affect the accuracy of the data.

But before the break tests can even happen, construction companies first need to be able to hire people that want to do the manual labor of filling and transporting concrete test cylinders. Headhunting requires a lot of time, financial resources, and human capital. With the severe labor shortage that the construction industry has been facing, the problem is only getting worse as time goes on.

Why Is the Construction Industry Afraid to Adopt Alternative Testing Methods?

Break tests are generally reliable and inexpensive mainly for small to medium-sized projects. However, there are better ways to measure concrete strength that are less costly in the long run. For example, wireless maturity sensors allow for real-time temperature and strength monitoring. They also eliminate the need for time-consuming break tests. Armed with this knowledge at any given time means that contractors and project managers know exactly when their slab is strong enough to begin the next phase of the project.

Interested in comparing maturity sensors to other strength testing methods?

The question is, why are people reluctant to use other methods? The construction industry isn’t known for welcoming innovation with open arms. But, that’s starting to change. After all, the first compression strength test was completed in 1836 and this method is still being used today. Old habits die hard. When something has carved itself a lasting place in history, people are afraid to challenge the status quo.

Ultimately, the construction industry simply doesn’t realize that problems with concrete cylinder testing exist because it’s the accepted standard. As a result, many people don’t know that there are other viable options available to them.

If someone spends their entire life riding a horse and buggy, would the thought of driving a high-speed piece of metal with four wheels and an engine enter their mind? The quote widely attributed to Henry Ford illustrates it best: “If I had asked people what they wanted; they would have said faster horses.”

**Editor’s Note: This post was originally published in April 2019 and was updated for accuracy and comprehensiveness in April 2025.

Sources:

Instron

Archtoolbox

The New York Times

Owlcation

Concrete Construction

2 Responses

Thank you for this informative article. Very useful.

Prof. Oukaili Nazar

University of Baghdad, Iraq

The article which you posted is very useful & informative for the readers.