Leading the Digital Concrete Revolution:

Intelligence in Every Pour

Explore Smart Concrete Solutions

Concrete Mix Optimization

Concrete Delivery

Temperature & Strength Monitoring

NDT & Lab Equipment

Concrete Mix Optimization

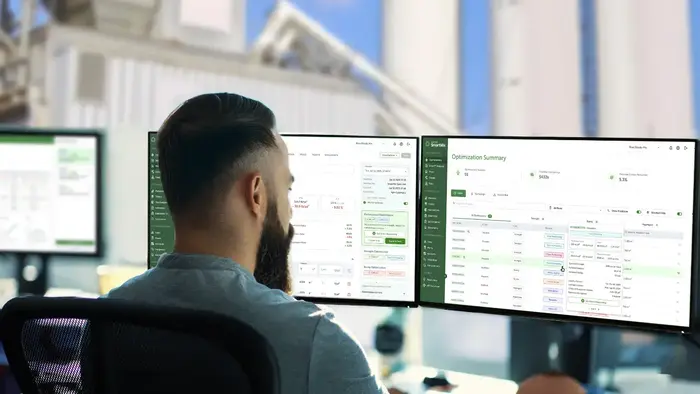

SmartMix™

AI-Powered Precision for Every Concrete Mix

SmartMix brings concrete data into a single digital platform. By integrating dispatch, telematics, and third-party systems, it delivers real-time visibility into operations, enabling smarter decisions, optimized mix performance, and more efficient workflows.Learn More →

Concrete Delivery

MixPilot™

Quality That Travels From Plant to Pour

MixPilot delivers precise, real-time concrete monitoring from plant to pour using a non-invasive, self-calibrating system. Wireless sensors and patented algorithms automatically calculate slump, temperature, and volume, providing reliable insights without manual calibration.Learn More →

Temperature & Strength Monitoring

SmartRock®

Concrete Temperature and Strength Monitoring

Precisely monitor concrete temperature under any conditions with wireless sensors and real-time remote monitoring.

Learn More →

SmartRock Long Range

A Long-Range Solution for Your Largest Project Sites

Bring confidence to your toughest projects with SmartRock Long Range, with an extended wireless range of up to 1000 ft (300 m).

Learn More →

SmartRock Pro

The 1st Fully Self-Calibrating Concrete Strength Monitoring Sensor

SmartRock Pro is the world’s 1st fully self-calibrating concrete strength monitoring sensor.

Learn More →

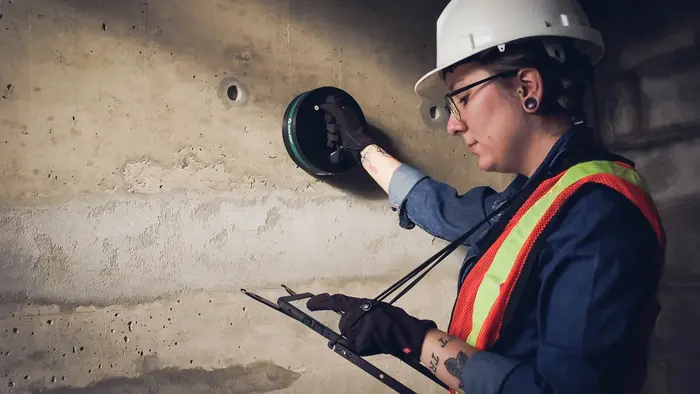

NDT & Lab Equipment

NDT & Lab Equipment

Advanced NDT & Laboratory Testing Solutions

Enable quick, reliable assessment of concrete quality and reinforcement conditions. Using patented corrosion rate detection and electrical resistivity technologies, these solutions support accurate evaluation of durability, corrosion risk, and chloride penetration in both field and lab applications.Learn More →

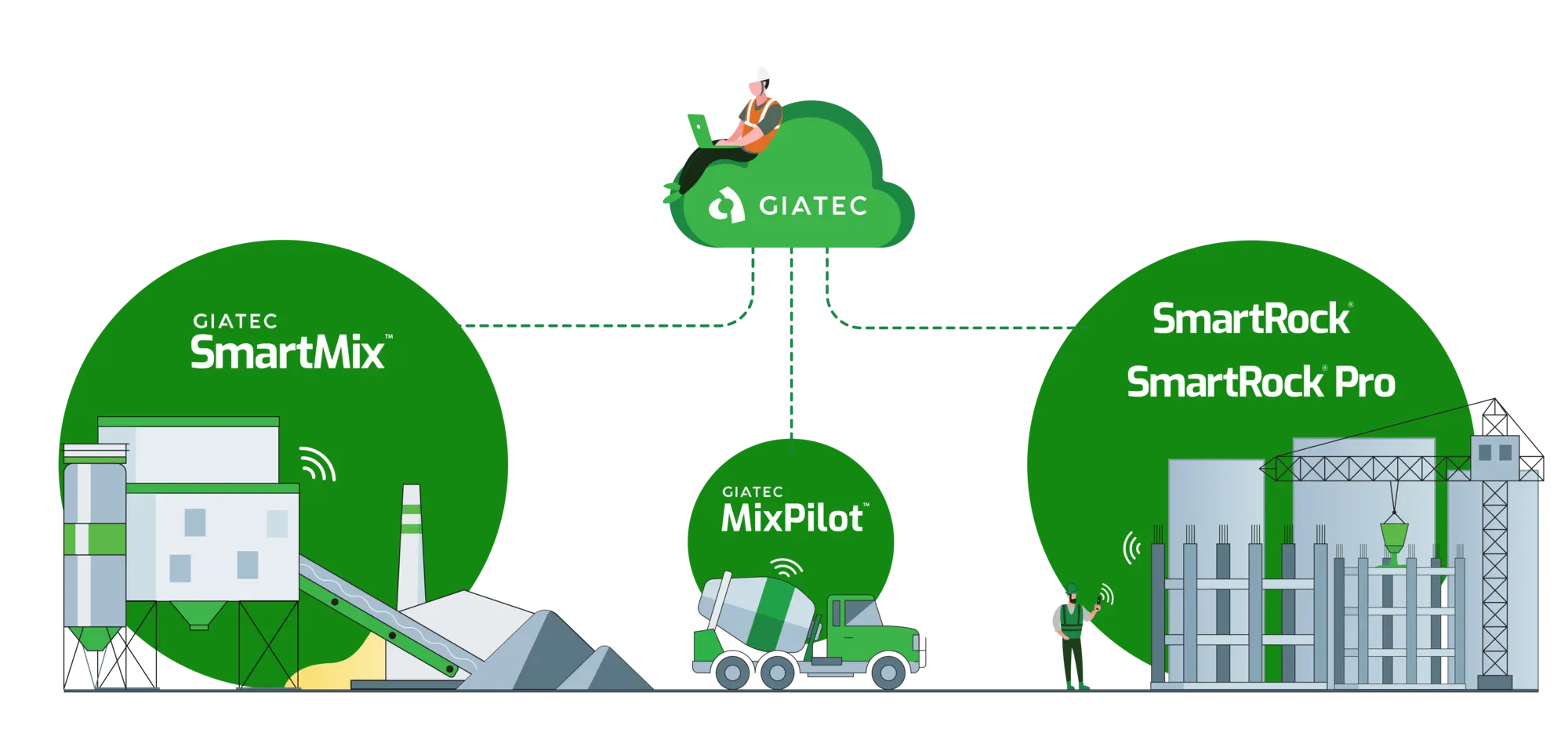

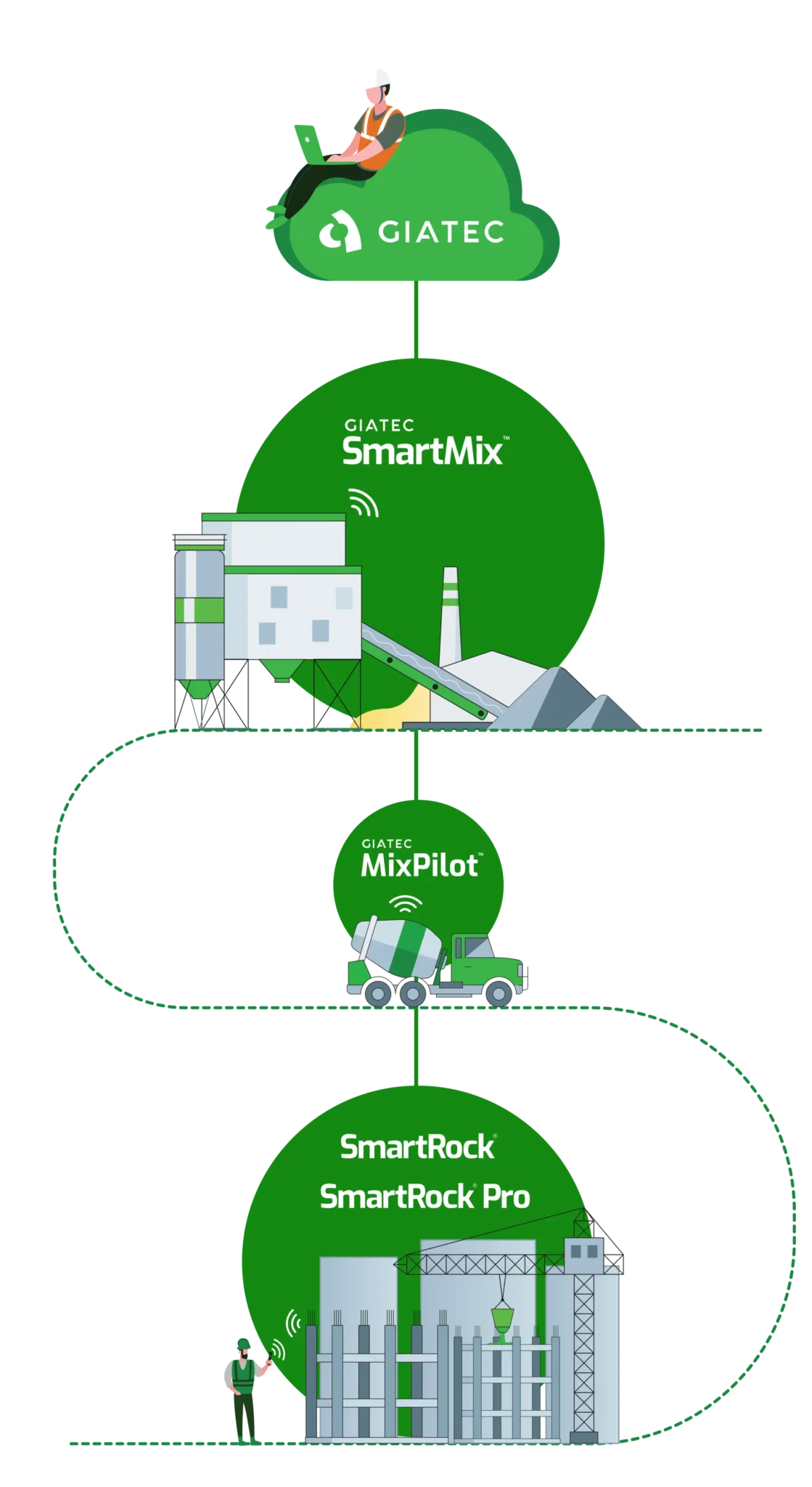

The Giatec Ecosystem

Giatec is a global technology company revolutionizing the concrete industry by enabling smart testing and real-time collection and analysis of concrete data, from production and delivery to placement. Our integrated hardware and software platform leverages advanced technologies to drive innovation across the concrete lifecycle while helping reduce concrete’s carbon footprint.

Giatec Events & Tradeshows

We’re taking the world by storm. Find out where we’re stopping next.

Case Studies

See rock-solid proof why ready-mix producers, project managers, and superintendents love to choose Giatec solutions.

SmartMix

Learn how SmartMix enabled 10x the efficiency in Modern Concrete’s workflows and a 300% ROI.

MixPilot

Five leading producers validated MixPilot under real-world conditions and transformed in-transit quality control.

SmartRock

See how Skyrise saved over 140 hours on their schedule for ONE Park Tower.

Knowledge Center

Your go-to construction industry hub for tip sheets, whitepapers, eBooks and more. Designed to help you stay at the forefront of industry innovation.

New! - Tip Sheet

The construction labor shortage is slowing down projects, raising costs, and stretching teams thin.

NEW! - Checklist

Download a comprehensive concrete pour checklist for general contractors and project managers to ensure the quality of your project.

New! - Ebook

Mass concrete pours are becoming more and more present in the construction industry.

Company News

Giatec is making headlines. Take a look at the latest reasons why!