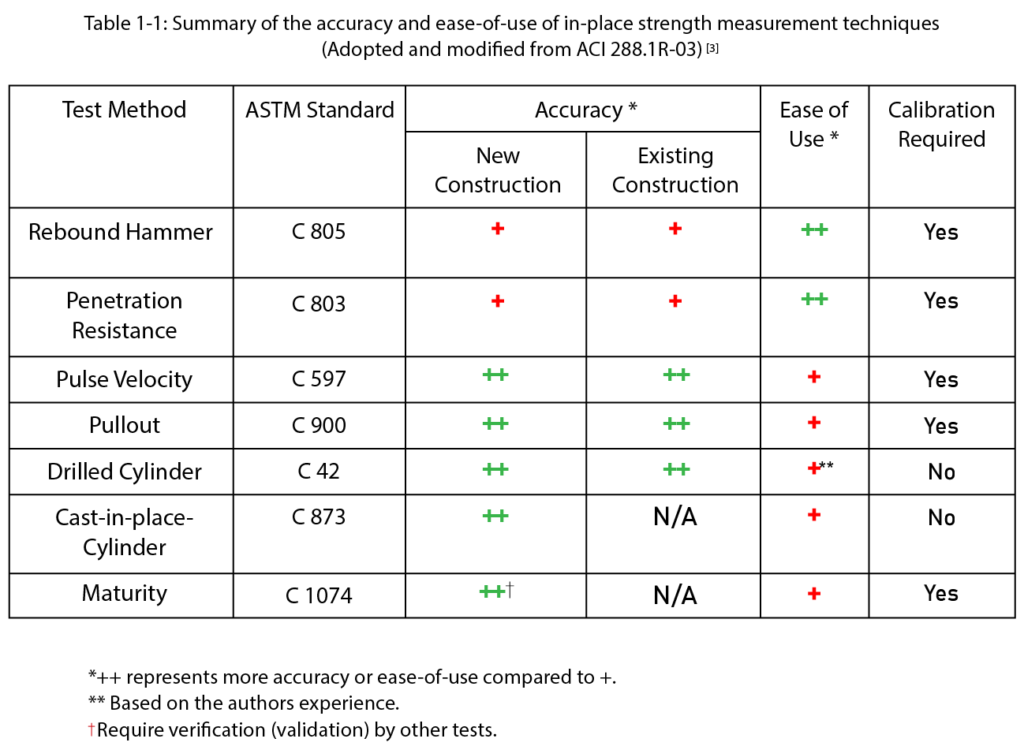

When choosing a method for concrete strength measurement and concrete field strength monitoring, it is important for project managers to consider the impact that each technique will have on their schedule. While some testing processes can be done directly onsite, others require extra time in external facilities that deliver strength data. Time is not the only factor that contributes to project managers’ decisions. The accuracy of the testing process is just as important as it directly affects the concrete quality of the structure.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Understanding Concrete Strength

Concrete strength is a critical measure of how well a concrete mix can withstand external forces without breaking or failing. It’s typically measured in terms of compressive strength, which refers to the material’s ability to resist crushing forces. The strength of concrete depends on several factors, including the quality of the raw materials, the water-to-cement ratio, the curing process, and environmental conditions during and after the pour. Accurately determining concrete strength is essential for ensuring the structural integrity and safety of buildings, bridges, and other concrete infrastructure. With modern advancements like wireless sensors, construction professionals can now monitor this vital parameter in real-time. These innovations provide more precise data and reduce the risk of premature failures.

What’s the Most Common Concrete Strength Test?

The most common method for monitoring the strength of in-situ concrete is the use of field-cured cylinders. This practice has remained generally unchanged since the early 19th century. These samples are cast and cured according to ASTM C31 and tested for compressive strength at various stages. Usually, if the slab has reached 75% of its designed strength, engineers will give the go-ahead to their team to move on to the next steps in the construction process.

There have been many developments to speed up the curing process since this testing method was first introduced. This includes the use of heating blankets, additives, and vapor retarders, etc. However, contractors still wait three days after their pour before testing for strength, even though their targets are often reached much earlier than that.

Despite knowing that, many project managers prefer to stick to this testing practice because it is “the way it has always been done.” However, that does not mean this technique is the fastest and most accurate method for testing the strength of all their pours. In fact, there are many different practices, aside from cylinder break tests, that can be used. Here are seven different approaches to consider when choosing a method of strength testing:

Methods for Testing Concrete Strength Measurement

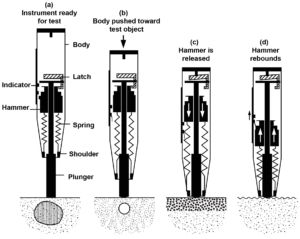

Rebound Hammer or Schmidt Hammer (ASTM C805)

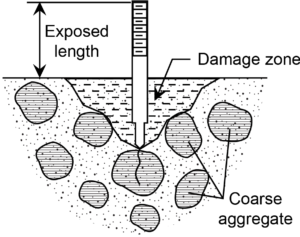

Penetration Resistance Test (ASTM C803)

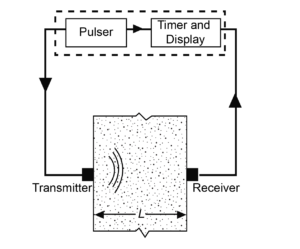

Ultrasonic Pulse Velocity (ASTM C597)

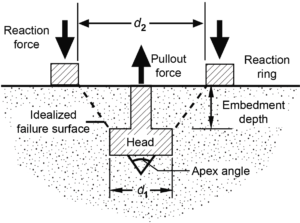

Pullout Test (ASTM C900)

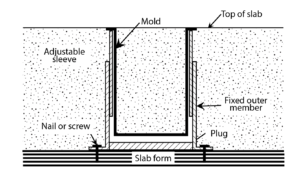

Cast-in-place Cylinders (ASTM C873)

Drilled Core (ASTM C42)

Wireless Maturity Sensors (ASTM C1074)

Method: This technique is based on the principle that concrete quality and strength are directly related to its hydration temperature history. Wireless sensors are placed within the concrete formwork and secured on the rebar before pouring. Temperature data is collected by the sensor and uploaded to any smart device within an app using a wireless connection. This information is used to calculate the compressive strength of the in-situ concrete element based on the maturity equation that is set up in the app.

Pros: Compressive strength data is given in real-time and updated every 15 minutes. As a result, the data is considered more accurate and reliable as the sensors are embedded directly in the formwork. This means they are subject to the same curing conditions as the in-situ concrete element. As a result, no time is wasted onsite waiting for results from an external lab.

Cons: Requires a one-time calibration for each concrete mix to establish a maturity curve using cylinder break tests.

Giatec’s Solution: Compressive Strength Test of Concrete

The high-tech and rugged SmartRockTM wireless sensors provide accurate real-time calculations based on the maturity method. More specifically, it allows you to collect the concrete’s temperature history, which is used to calculate the maturity index of concrete. This enables you to predict its early-age compressive strength. Keep in mind that the standard level of strength for post-tensioning is 75% and, in some cases, your concrete can reach this level of strength sooner than expected. By employing the maturity method, you will be able to closely monitor when your concrete reaches the necessary level of strength. Thus, you can know when to safely move forward post-tensioning as soon as possible!

Furthermore, as a non-destructive method, SmartRock requires its sensors to be embedded into the concrete. This eliminates the need for time-consuming and costly cylinder break tests.

The Giatec Ecosystem of Hardware and Software Solutions

SmartHub™ is a remote monitoring system that allows you access to your SmartRock data anytime, anywhere. Easily installed on rebar before pouring, these user-friendly sensors monitor in-situ temperature and field strength in real time. The Hub automatically collects this data recorded by the SmartRock sensors and uploads it to the Giatec 360™ cloud dashboard via LTE, syncing it to your team’s mobile devices in the SmartRock app. The Giatec 360 alert system sends smart notifications to let you know when your concrete reaches specific thresholds.

SmartMix™ is a web-based dashboard that enables producers to optimize concrete materials and predict the performance of their mixes. With the SmartMix dashboard, producers can adjust the proportions of their concrete mixes, such as the use of chemical admixtures and the amount of cement. With the help of Roxi™ and access to millions of data points used to train the artificial intelligence algorithm, the dashboard’s suggestions ensure that these adjustments will meet a mix’s designed compressive strength and other performance criteria.

Learn more about concrete maturity here

Combined Methods of Concrete Strength Measurement

A combination of these methods for measuring the compressive strength is sometimes used to ensure the concrete quality control and quality assurance of a structure. A combined method results in a more comprehensive overview of your slab. This allows you to confirm strength data by using more than one testing method. The accuracy of your strength data will also increase as using multiple methods will help account for influencing factors, such as cement type, aggregate size, and curing conditions. For example, a combination of the ultrasonic pulse velocity method and the rebound hammer test has been studied. Similarly, when using the maturity method on your jobsite to test compressive strength, it is recommended to perform cylinder break tests on day 28 of your concrete’s lifecycle for acceptance purposes and to confirm the strength of your in-situ slab.

How to Decide Which Concrete Field Strength Method to Use for Your Next Pour

Tests like the rebound hammer and penetration resistance technique, while easy to perform, are considered less accurate than other testing methods (Science Direct). This is because they do not examine the center of the concrete element. They only examine the curing conditions directly below the surface of the slab. Practices, such as the ultrasonic pulse velocity method and the pullout test, are more difficult to perform as their calibration process is lengthy. This requires many sample specimens to obtain accurate data.

Destructive Testing vs. The Maturity Method

As destructive testing techniques, the drilled core and cast-in-place cylinder methods need other parties to perform break tests in order to get data. As a result, more time is needed in your project schedule when using either of these methods. Comparatively, with the maturity method, you can get strength data in real-time directly on-site, allowing for well-informed and quick decision-making. By reducing your reliance on break tests, you can also avoid inaccuracies associated with testing labs.

Learn more about wireless concrete sensors, like SmartRock® Here

Conclusion

Your decision in choosing a testing method for concrete strength measurement may simply come down to familiarity. However, the accuracy of these tests and the time they take to obtain strength data are significant factors that are often overlooked. Think about where all your time and money go during the construction of a project. How much of that is spent on repairs, fees for labs, and extra labour to make sure your project finishes on time? The accuracy of the technique you choose can lead to future durability and performance issues of your concrete structure. Furthermore, choosing a technique that takes additional time to receive strength data can be detrimental to your project deadlines. This negatively impacts productivity on your jobsite. Conversely, choosing the right tool can positively impact project timelines and allow you to finish the project below budget. How do you decide which strength testing method to use?

Sources:

Science Direct

Concrete Maturity: From Theory to Application

Concrete Network

*Editor’s Note: This post was originally published in April 2019 and has since updated for accuracy and comprehensiveness.

10 Responses

Great insights! I never considered the lesser-known method you mentioned. It’s a useful addition to the more common testing techniques. Thanks for sharing!

Great article, exactly what I needed.

It’s a great source of knowledge; I think it will be helpful for lot of people who are looking for learning more about the 6 ways you know to test concrete strength and you may not have heard. Thank you very much for sharing this article.

I’m glad that you explain how ultrasonic pulse velocity is a non-destructive testing technique that sends vibrational energy through the concrete to test the elasticity, resistance, and density. If someone wants to choose this, it would probably be a good idea to research local companies online. This way, you can learn about the method they use and their experience in order to find one that knows what they’re doing and has the best equipment so that the test results are accurate. You’d probably want to also check their communication skills to ensure they’ll explain the results in a way that you’ll understand.

Active monitoring as that offered by wireless

concrete sensors is needed on construction

sites, the monitoring may be started after 10

hours of casting.

Obsession of concrete contractors are:

The casting inhabit accepted ITZs, having

no ettringites or no DEFas a result of attacks,

and of balaced curing.

The resulted data in implementing maturity

concept are proofs added help to determines

setting time,ease to create data in cloud and

plotting s curves.

I have studied the mentioned methods and the concept of maturity of concrete in a Master’s degree program in Kuwait University in the 1986. before 5 years I came to see and know the concrete wireless thermostat and its application.

Have encountered many colleagues in my life with construction, I unfortunately found most of them have no idea how many non-destructive test methods and applications are available.

I’m glad the your article addresses this very good to know techniques and information.

MUY BUENA INFORMACIÓN, CONVENIENTE CONOCER MÁS ACERCA DE LOS SENSORES DE MADUREZ.

SALUDOS!!

This is a really great article. Thank you for posting this. its very informative.

First time i learned 6 ways to test the concrete strength, Thankyou so much.

I am all for taking human error out of the process of concrete sampling, curing and testing. But as with any in place testing, results can be skewed by placement methods and curing procedures that are out of the RMC producers control. It’s still not an accurate method of the concrete mix designs potential which is what we submit as proven. Thus we would be held accountable for these inaccuracies.