Problem

In 2019, Field Engineer, Jackie Odom and Project Manager, Dinesh Allam, began work on a 3-million-gallon underground stormwater containment reservoir for the San Diego International Airport. The main requirement of this project was to ensure the long-term durability of the concrete structure as being underground meant it would be exposed to seawater.

Due to the exposure class during its service life, the 25-foot underground structure required that the reinforced concrete walls have a thickness of 2-8 feet. The concrete had a very high cement content and had very strict crack requirements. This led to a possibility of getting high internal concrete temperatures as the walls are considered to be mass concrete elements. This resulted in two main challenges for the Sundt team that required continuous temperature monitoring:

- Maintain maximum temperatures below a certain threshold

- Limit the temperature differential between the core and the surface of the element

Those two requirements were critical to ensure that the structure would not show signs of cracking due to thermal cracking and delayed ettringite formation (DEF).

Solution

As this project required consistent and accurate temperature monitoring, three different concrete mock-ups were done in the initial stage of design to simulate the concrete temperature behavior during the early stages. This test was done to ensure that the concrete temperature would not reach the specified limits.

The initial mock-up showed that additional cooling was needed at the mixing stage and that different forms of insulation might be required to maintain an acceptable temperature gradient between the core and the surface of the concrete element. After addressing these challenges, the latest concrete mock-up showed that they had a good mix design and proper measures put in place to achieve optimal performance for the actual placements.

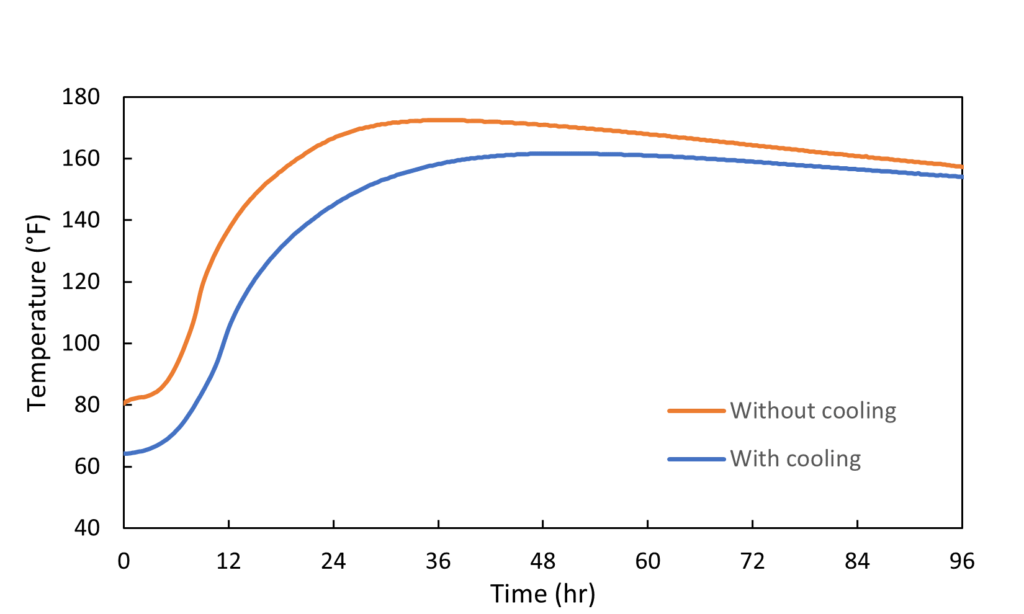

The following graph represents the adiabatic condition of the concrete during the mock-ups and shows how the cooling methods helped reduce the heat rise of the concrete at the core.

During this mock-up process, many temperature monitoring devices were tested and compared. Project Manager Dinesh Allam chose Giatec’s SmartRock® wireless temperature and strength sensors because they allowed the team more flexibility in terms of the installation location where the temperature of the in-place concrete could be measured and the sensors had a better overall pricing model.

Results

The placement consisted of the mat slab, followed by the one-sided walls, and the Cistern lid of the tank in which temperature was measured for each pour. In this project, both the short cables 12 in (30 cm) and long cables 10 ft (3 m) that SmartRock offers were used in order to capture the highest temperature at the center of the concrete and the lowest temperature near the surface of the concrete.

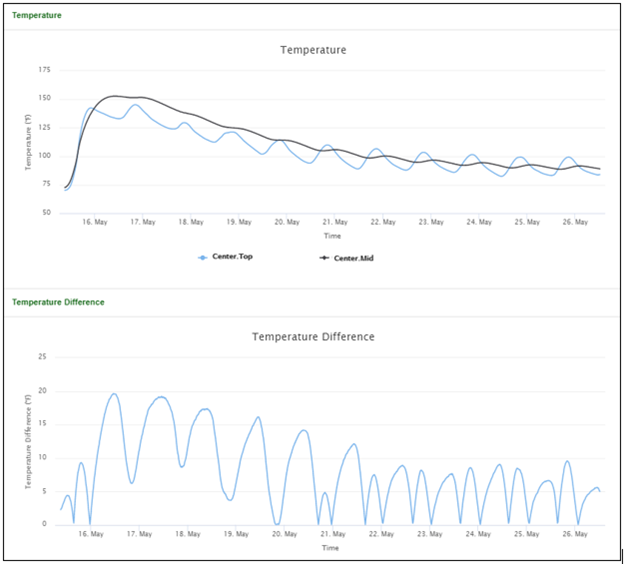

Sundt also implemented the full Giatec solution on this project, including the SmartHub™ device and the Giatec 360 cloud-based platform. SmartHub is a remote monitoring system that allows you to connect to your SmartRock sensors and obtain real-time data from any location. Giatec 360 is an online platform offering a variety of features, including easy temperature gradient analysis. By using the full solution, Sundt Field Engineer Jackie Odom was able to easily access data and send customized reports to the team.

“I find the gradient analysis feature is extremely helpful because before that feature [in Giatec 360], we would have to do it in our own spreadsheets and manipulate it. So, having that and having it convert into the CSV file and the PDF saved me a lot of time.”

Jackie Odom, Field Engineer, Sundt Construction Inc.

“Those were really good high-level numbers and to the point, and those are the numbers which matter.”

Dinesh Allam, Project Manager, Sundt Construction Inc

As the use of any new system comes with its challenges, Jackie Odom did not hesitate to contact the support department at Giatec when questions arose. She was pleased to receive a level of support that exceeded her expectations.

Overall, the consistent temperature monitoring made it possible to optimize the cooling requirements of the concrete. This allowed for a 40% savings in cooling material on this project. Sundt is currently optimizing the use of the SmartRock sensors and is planning to implement the maturity method on their next project.

“Giatec has one of the top products out there!”

Dinesh Allam, Project Manager, Sundt Construction Inc.