As the leading wireless sensor for monitoring concrete temperature and strength, SmartRock® gives you reliable and accurate data in real-time. The sensors are fully embedded in the concrete (secured on the rebar) before pouring. Temperature is constantly monitored by the sensor and is used to calculate the compressive strength of the in-situ element based on the maturity method. This means you know as soon as possible when your project is ready for the next steps in the construction process. Wanting to ensure you can get this information before you even head to the jobsite, so that you can plan your day ahead of schedule, we created SmartHub™, a remote monitoring system to access the SmartRock sensor data from anywhere anytime.

What is the SmartHub Remote Monitoring System?

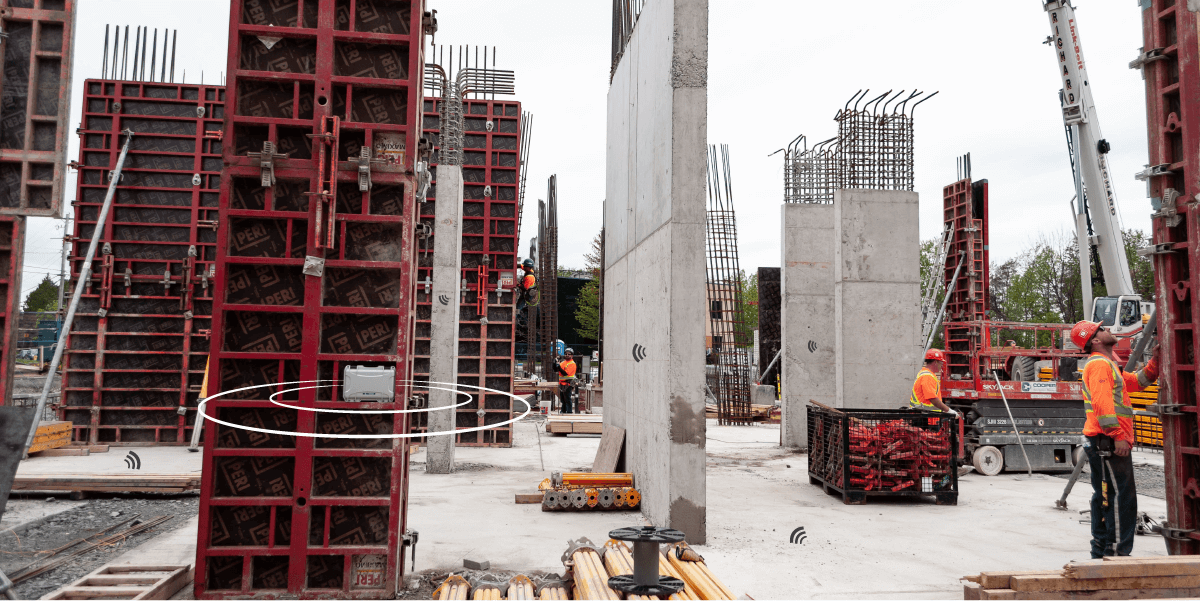

SmartHub is a remote monitoring system that allows you to access your SmartRock sensor data at anytime, from anywhere. SmartRock is the most widely used wireless concrete sensor in the world, helping construction companies build structures faster, safer, and more efficiently. These user-friendly sensors are easily installed in the concrete formwork (on the rebar) before pouring to monitor your concrete’s in-situ temperature and strength in real-time. The Hub automatically collects this data recorded by the SmartRock sensors and uploads it to the Giatec 360 cloud dashboard via LTE/Wi-Fi where it is synced to your team’s mobile devices in the SmartRock app. The Hubs alert system sends smart notifications to let you know when your concrete reaches specific temperature or strength thresholds. With real-time information you know when your project is ready to move on to the next steps in the construction process, allowing you to optimize your schedule.

Access Your Concrete Data 24/7 With SmartHub in Three Easy Steps

1. Install the Hub

As a rugged, waterproof design, the SmartHub can withstand any weather conditions. All you have to do is secure the device on your jobsite.

2. Open the SmartRock App

On the tablet provided, open your SmartRock app and sign in with the Hub user that can be created on the Giatec360 web-dashboard.

3. Get Real-time Results

Once logged in, the SmartHub will automatically scan your jobsite for SmartRock sensors and collect temperature and strength data which are then uploaded to the Giatec360 cloud and synced to your team’s mobile app.

Learn more about the SmartHub here!

SmartHub Features

Software

- 24/7 data collection and analysis of multiple sensors

- Real-time data display (temperature, strength, max-min values, and graphs)

- Maturity calibration database

- Free Android app included with tablet

- Free Giatec 360 desktop account (required)

- Easy data sharing between team members

- Project management tools including live data sharing

- Full PDF & CSV reporting and data exporting

Hardware

- Wire-free and wireless technology

- Android tablet

- Rugged and wireless design

- Easy installation and activation

- Battery charger

- LTE compatible with all Canadian providers, AT&T, and T-Mobile

Optimize Your Project Schedule with SmartHub

Before starting a new project, it’s often unknown what type of jobsite you are going to end up working on and where it’s going to be located. Whether it is a dam, a bridge, or a commercial site, the faster the method of concrete strength testing gives you your data, the better you can optimize your project schedule and ensure you are sticking to your timeline. When working on an inconvenient and remotely located jobsite choosing a method that will not delay your schedule can be a challenge.

With cylinder break tests it takes time to cast the specimens, arrange for a lab to pick them up, and then wait for the tests to be completed to get the data sent back to you. Even if you are using a quicker method of strength testing, such as a wired system, it would still take time to have one of your team members go on site and plug into each wire using a data logger to get this information. Not only is this inconvenient, it can also be dangerous depending on the terrain of your jobsite. But, with a remote monitoring system, like SmartHub, there is no need to visit the site to get this data, it is sent directly to your mobile device in real-time. You can set up the hub and not have to worry about when you are going to get concrete strength data. Not only does this minimize delays and save you from wasting time and money by having an unnecessary number of workers on your jobsite, it also boosts your productivity.

With the SmartHub’s alert system and Roxi’s artificial intelligence capabilities, you will also receive smart notifications to let you know when your concrete reaches specific temperature gradients or strength thresholds so you can tell your team right away to start tensioning cables, strip forms, or adjust curing conditions. This critical information will also help you identify any problems with your concrete right away, such as a broken-down heater, resulting in a drop in temperature. With the SmartHub remote monitoring system you can therefore make quick decisions immediately before they result in delays on your project, ensuring your jobsite it faster, safer, and more efficient.

Download the SmartHub flyer with device specifications Here

**Editor’s Note: This post was originally published On May 2019 and has been updated for accuracy and comprehensiveness.

8 Responses

Is the SmartHub approved and available for Australia at all please?

Hi Mike, the SmartHub™ is currently available in North America. We will announce as soon as it becomes available internationally. Thank you for your interest.

I had experience with smartrock sensors around 55 units, works very well until earlier ages for normal strength resistance at 28 days, but with concrete with C3A < 5% they reach the final strength beyond 56 days, none of the sensors reach 56 days, with temperatures beyond 83 celsius the sensors fails.

Hi Gustavo, our SmartRock™ sensors are primarily used for monitoring the early-age strength of concrete for the first 28-days after your pour. This is to help you know right away when critical operations can be completed onsite, such as formwork removal or post-tensioning. After 28-days time, while concrete continues to gain strength, strength development at this time is very minimal. However, SmartRock does have the ability to monitor temperature and strength data for 60 days. If you would like more information on this issue, we encourage you to contact our IT support at +1 (877) 497-6278 or support@giatecscientific.com.

What’s the maximum distance between SmartHub and the sensor to ensure signal is not lost??

If we have a huge site, could we install multiple SmartHub devises?

What about the battery life of SmartHub?

Hi Njoud, thank you for your comment. The wireless range and battery life are dependent on various conditions. Please contact one of our experts at sales@giatec.ca for more information on how SmartHub™ can be used on your latest jobsite.

Is it also working in Europe?

Hi Wilfried, the SmartHub™ is currently available in North America. We will announce as soon as it becomes available internationally. Thank you for your interest.