Mass Concrete

Enhance your mass concrete projects with SmartRock® Long Range remote monitoring solution for accurate temperature monitoring.

Mass Concrete

Enhance your mass concrete projects with SmartRock® Long Range remote monitoring solution for accurate temperature monitoring.

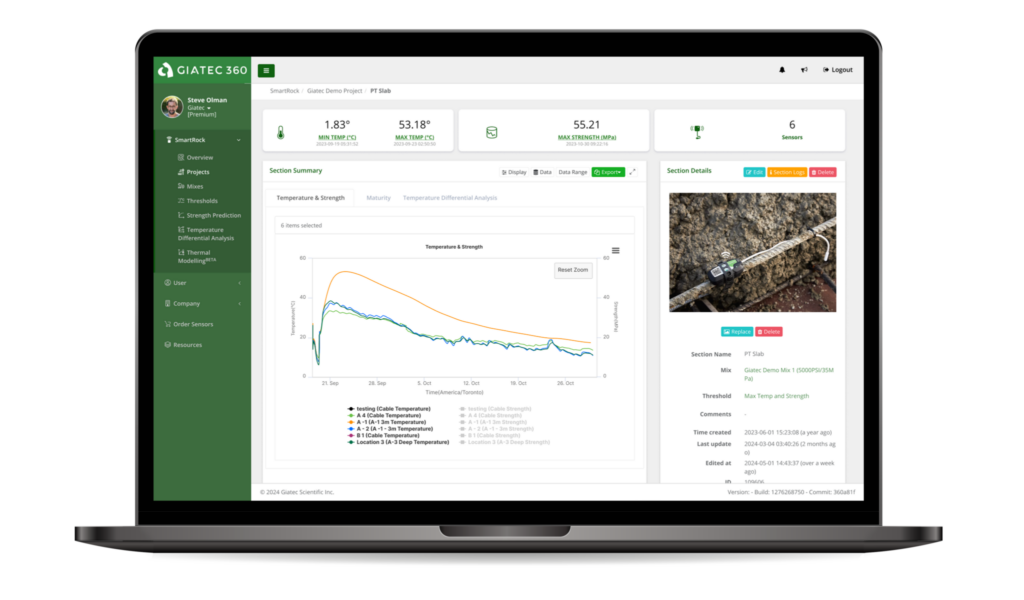

Gain real-time insights into concrete temperature differentials between core and surface using data from the Giatec 360™ platform and SmartRock App.

Dual temperature monitoring of mass concrete with SmartRock Long Range sensors ensures optimal curing and enhances structural integrity and longevity. This prevents thermal cracking and improves concrete quality.

Contractors can have an extended monitoring range up to 1000ft (300 m), giving them full control over concrete temperature data from any devices for their largest job sites.

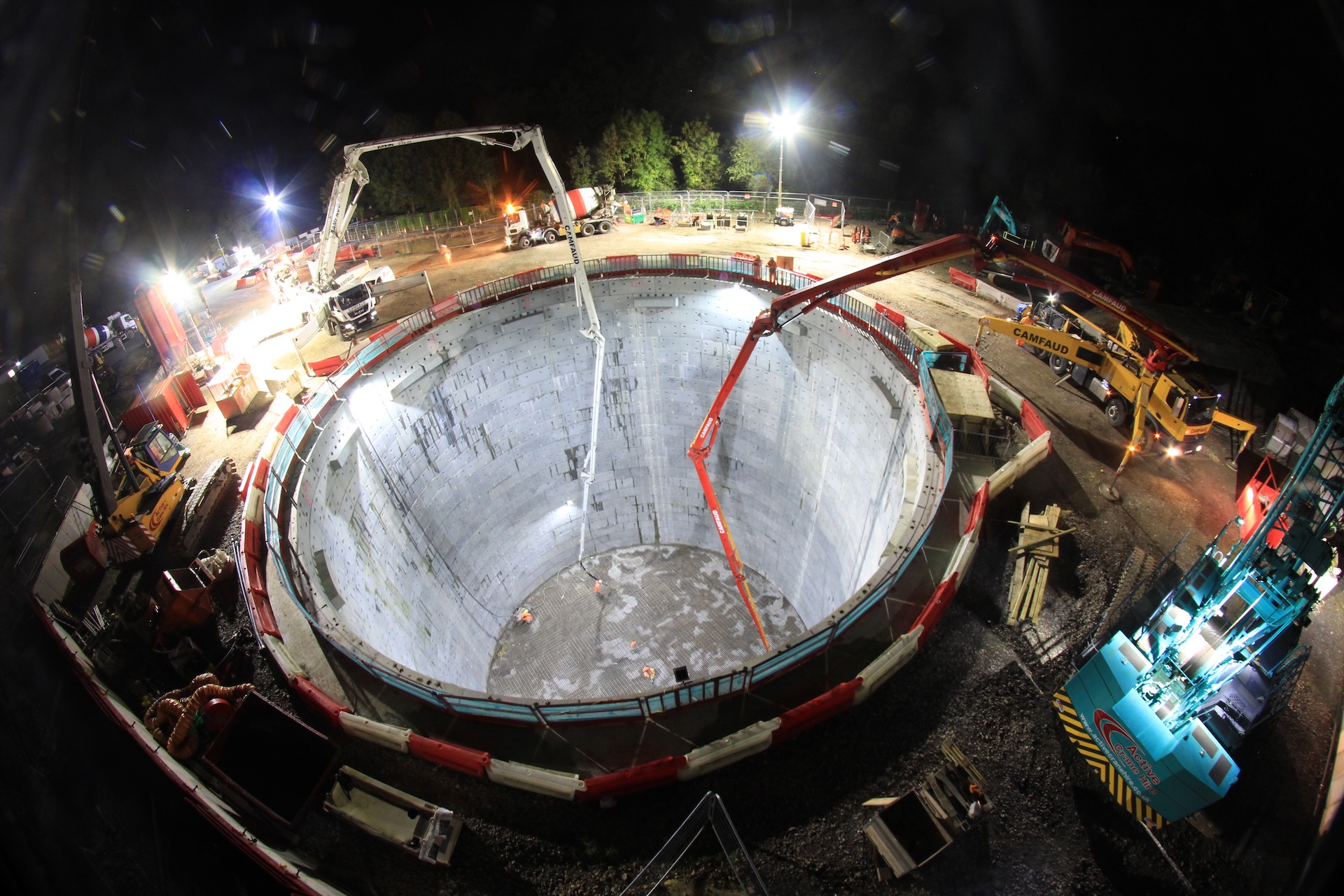

According to the American Concrete Institute (ACI), mass concrete is any volume of concrete with dimensions large enough to require that measures be taken to cope with the generation of heat from the hydration of the cement and attendant volume change to minimize cracking.

Temperature monitoring in mass concrete structures is a critical practice for ensuring the integrity, strength, and longevity of concrete. Due to the exothermic nature of the cement hydration process, large volumes of concrete can experience significant temperature gradients between the core and the surface. These gradients can lead to thermal stresses, which may cause cracking and compromise the structural integrity.

A Long-Range Remote Monitoring Solution for Your Mass Concrete Projects

Boost confidence in your projects with long-range remote monitoring for concrete structures, ensuring reliability and minimizing on-site visits. Now available across North America and select countries.

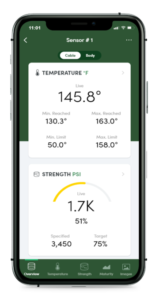

The SmartRock mobile app provides real-time access to concrete data either on the jobsite through direct communication with the sensor, or remotely via the SmartHub system.

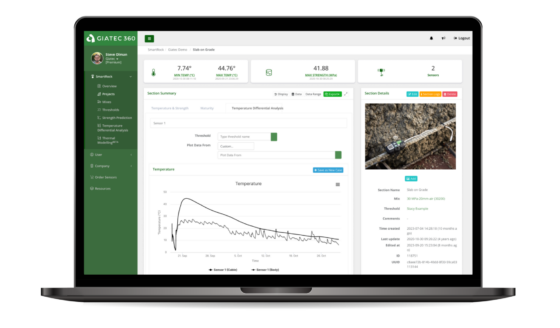

Cloud-Based Project Dashboard

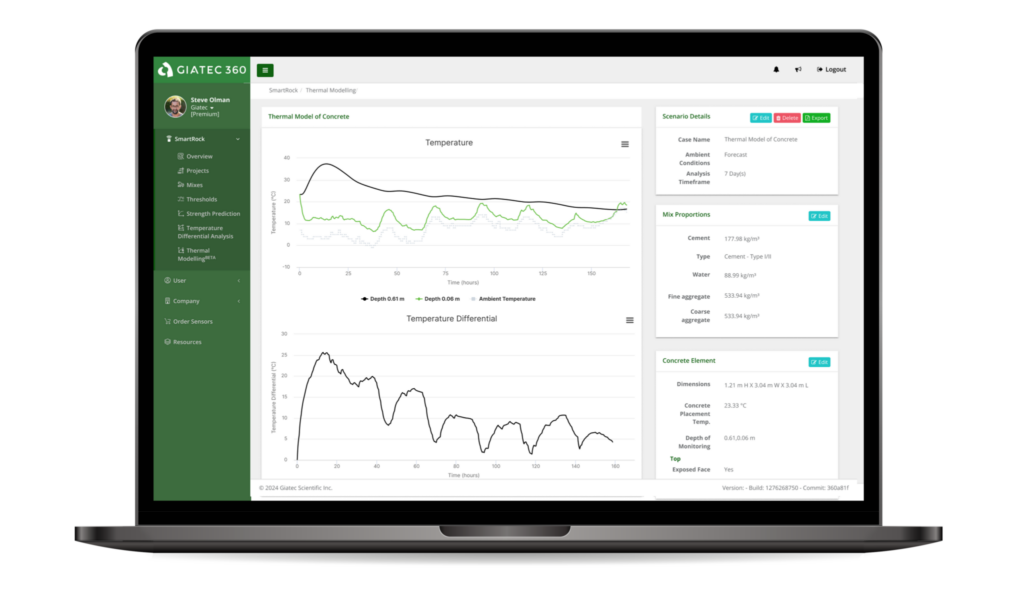

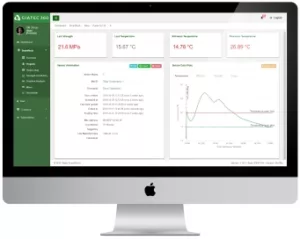

Giatec 360 is a comprehensive project management tool with advanced data analytics for evaluating concrete mixes, monitoring projects, and gaining detailed insights into temperature data with a thermal modelling feature

Built-In Artificial Intelligence Assistant

Roxi is the first machine learning algorithm for concrete materials that has been trained with millions of data points to offer smart suggestions and detect anomalies in concrete performance.

Project Data Integration

SmartRock can be easily integrated with any construction project management software. Automatically populate data on concrete quality on your preferred platform to generate action items and triggers on the next steps of your construction project.

Concrete temperature and strength monitoring is essential to ensure proper curing, strength development, and prevention of thermal cracking in high-rise foundations and heavy civil projects like transition beams.

In mass concrete projects like bridge elements, temperature monitoring ensures uniform curing, prevents cracks, and maintains structural integrity.

Concrete temperature monitoring sensors are essential in piers and large foundations projects to control mass concrete construction, optimize curing processes, ensure quality control, and comply with specifications.

Mass concrete temperature differentials are one of the leading causes of thermal cracking in large concrete pours. When the internal core heats up during hydration while surface temperatures cool, tensile stresses develop that concrete cannot withstand. Without proper monitoring, these stresses result in early-age cracking, reduced durability, and costly repairs. Closely monitoring concrete temperatures is critical for ensuring proper strength development of concrete structures and concrete sustainability regardless of their application or size. However, when it comes to mass concrete structures, we need to consider temperature differentials due to the risk of a large difference between the relatively hot internal temperature and the cool surface temperature. If a too-large temperature differential occurs, the surface of mass concrete will start cracking. This is detrimental to its durability and the length of its service life. In this blog, let’s take a look at why managing mass concrete temperature differentials is important for preventing thermal cracking and ensuring long-term structural durability. What Is Mass Concrete? Mass concrete is not defined by any specific measurements. According to the American Concrete Institute (ACI), mass concrete is “any volume of concrete with dimensions large enough to require that measures be taken to cope with the generation…

Every concrete professional aims to perform critical operations faster and with the highest possible quality. Remote monitoring systems such as the SmartHub™ Long Range developed by Giatec are valuable tools for this need. Following the first part of the long-range series, this blog will delve into the applications of the SmartRock® Long Range. Learn the ins and outs of mass concrete pours Fully Embedded Wireless Systems The proliferation of wireless sensory technology has been incredibly helpful in harnessing vital information from structural elements in the last couple of decades. A lot of construction projects are taking advantage of this technology and have fully embraced embedded solutions. This is because they are reliable and easy to use, giving real-time data of the in-place element. Due to this added value, some project specifications will specifically require the use of fully embedded and wireless systems. However, despite technological advances, there are certain jobsite characteristics where the range of data transmissibility with standard solutions could be a challenge. Also, there could be a demand for real-time monitoring of concrete conditions, which requires constant data acquisition from the sensors installed. Remote project locations and on-site structural elements with limited accessibility of human personnel could hinder…

Thermal Modeling is Giatec 360™’s first-of-its-kind new feature that can be used to predict concrete temperature in a mass concrete element. This helps to limit the potential of long-term and short-term cracking and increases the concrete’s quality and long-term durability.

SmartRock® Long Range helps protect schedule and quality on data center construction. Get a FREE quote today!