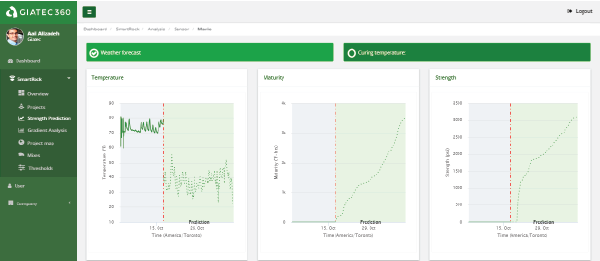

Giatec 360™ is the world’s most advanced web-based dashboard for controlling and predicting the quality of concrete pours. With this latest online concrete monitoring software, you are introduced to the next level in user management capabilities. These range from data reporting and data analytics for your SmartRock® wireless sensors. Once you have installed SmartRock sensors onsite, information regarding the temperature and strength of your concrete is available through the SmartRock mobile app. Furthermore, you can log in to the Giatec 360 dashboard online and gain access to additional features that give you even more insights into your concrete structures.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Learn More About Your Concrete With This Online Concrete Monitoring and Testing Reporting Software

The Benefits of SmartRock Wireless Sensors

SmartRock is a rugged, mobile-based wireless sensor that is fully embedded in concrete to monitor temperature and strength. As the most widely used wireless concrete sensor in the world, SmartRock has helped construction companies in many countries to build structures faster, safely, and more economically.

These user-friendly sensors are easily installed in the concrete formwork (on the rebar) before pouring to monitor in-situ temperature and maturity according to ASTM C1074. The wire-free logger continuously records the measured temperature of any concrete pour in real-time. Subsequently, contractors can download these results and analyze them automatically onsite. Using the free SmartRock app, they can determine the in-place concrete strength.

Finally, the temperature history along with a calibration curve of your slab allows you to calculate the real-time strength of your concrete. When this information is calculated, online concrete monitoring becomes easy. In that context, an analysis of the temperature and strength of your concrete is updated in your SmartRock mobile application at regular 15-minute intervals.

How Can This Help?

With real-time results, contractors can optimize the heating process, decrease energy costs, and save time in their project schedules. They will know precisely when they can move on to subsequent construction operations, such as formwork removal or post-tensioning. Therefore, the use of these wireless sensors eliminates the need for break tests onsite, saving you time and money.

Read more about SmartRock here

Monitor and Control Your In-Situ Concrete with Giatec 360

In addition to the features available on the app, the Giatec 360 desktop dashboard allows you to;

- Gain insights into the performance of your concrete mixes in real-time

- Manage user access levels and sensitive project data

- Assign role-based access to data

- Measure real-time concrete strength prediction

- Monitor multiple projects at the same time

- Analyze temperature gradient data and maturity threshold data

- Plot data between multiple sensors

- Edit your mix calibration data

- Receive push notifications on your mobile device

- Generate PDF/CSV reports for distribution

- View user activity logs and connected devices

- And all upcoming features!

Learn more about the important of temperature monitoring and concrete temperature gradients!

In addition to online concrete monitoring and managing your pours, Giatec 360 gives you control of your project data. With this dashboard you can optimize all of the features of your SmartRock wireless sensors. Thus, it provides valuable insights needed to make fast and efficient decisions on all construction projects.

*Editors Note: This post was originally published in April 2021 and has been updated for accuracy and comprehensiveness in July 2023.