The Project

Mott MacDonald, the management and consultation firm, has taken over their few shares of big international construction projects, some of which have earned well-deserved awards over the years. Their presence in the UK is stellar as they have actively contributed to the improvement of the transportation sector. One of their most recent projects came in partnership with National Highways for the renovation of the Norfolk transportation network, on the East of England. While setting the groundwork for the project, Mott MacDonald had to evaluate different rapid early strength mixes and compare them to conventional pavement quality concrete. The results of their assessment would allow them to decide on the use of temperature match curing and determine reopening times as efficiently as possible without the need for destructive testing, considering the repair work gets done at night.

How to Deal With Rapid Early Strength Concrete?

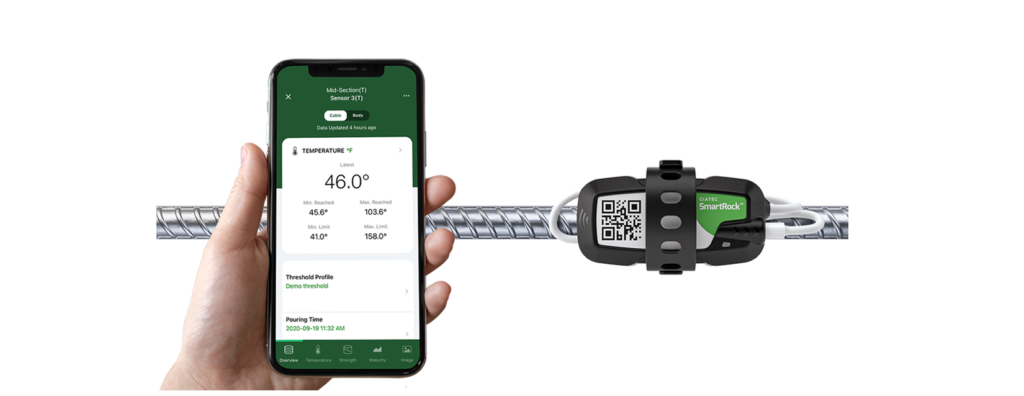

Faced with a demanding timeline and limited nighttime availability, the team operated with a keen focus on precision and efficiency. The nightly closure, running from 10:00 PM to 5:00 AM, left no margin for error. During each night shift, the goal was to replace 25 by 5-meter sections of the road. The critical aspect was performing a swift replacement and ensuring that the newly laid concrete attains the necessary strength for traffic use by 5:00 AM. Supplier assurances dictate that the concrete mixes they employ should achieve the required strength within a four-hour timeframe. In a quest to validate this under real-world conditions, the team turned to laboratory testing and leveraged the innovative SmartRock® technology. The significance transcends mere strength verification; it’s about achieving these goals by diminishing the complexities associated with laboratory procedures like coring or cube crushing. SmartRock emerged as their indispensable tool in efficiently and effectively meeting these stringent demands.

Aiming to Reduce Destructive Testing

Mott MacDonald’s adoption of SmartRock stemmed from its remarkable convenience, granting them access to real-time data on their mobile phones. This technological shift was prompted by a recommendation from a trusted supplier who had witnessed the success of SmartRock. Their primary objective revolved around gauging concrete strength gain without the need for destructive testing, a critical consideration given their repair work often occurred during nighttime closures. The team’s focus was on simplifying and expediting the process, and SmartRock was used to verify in situ conditions, reducing the need to transport concrete cubes to a lab for testing. This was particularly crucial as certain early-strength concretes they used generated high initial temperatures, reaching 30° Celsius. However, the confinement of concrete in cubes dissipated much of this heat, impacting the accuracy of their strength assessments. By directly measuring performance in situ, they aimed for greater precision, reliability, and confidence in confirming the concrete’s requisite strength. This was key for the safe reopening of traffic in the morning.

Adopting SmartRock Technology Ensures Efficiency and Smooth Operations

Mott MacDonald’s team experienced a seamless transition to SmartRock sensors, as they were user-friendly and easily integrated with their systems and mobile devices. The sensors could be conveniently strapped onto the structures and performed exceptionally well. The team meticulously set up the sensors to ensure redundancy within each slab, particularly during their trials at a depot rather than on the road network. They strategically positioned the sensors at various points, assessing both slab corners near the edges and the slab center to gauge temperature and performance variations across the concrete. This approach proved successful, as all the sensors operated without malfunction or variation. The SmartRock technology was smoothly embraced by the entire team without challenges in operation. Most team members, including the engineers, were actively engaged in monitoring and downloading the sensor data using the sensor’s mobile app, ensuring a constant stream of information for their projects. Overall, SmartRock allowed Mott MacDonald to complete the National Highways project with great success, while minimizing the need for destructive concrete testing.