Schmidt Hammer (or Rebound Hammer) Method

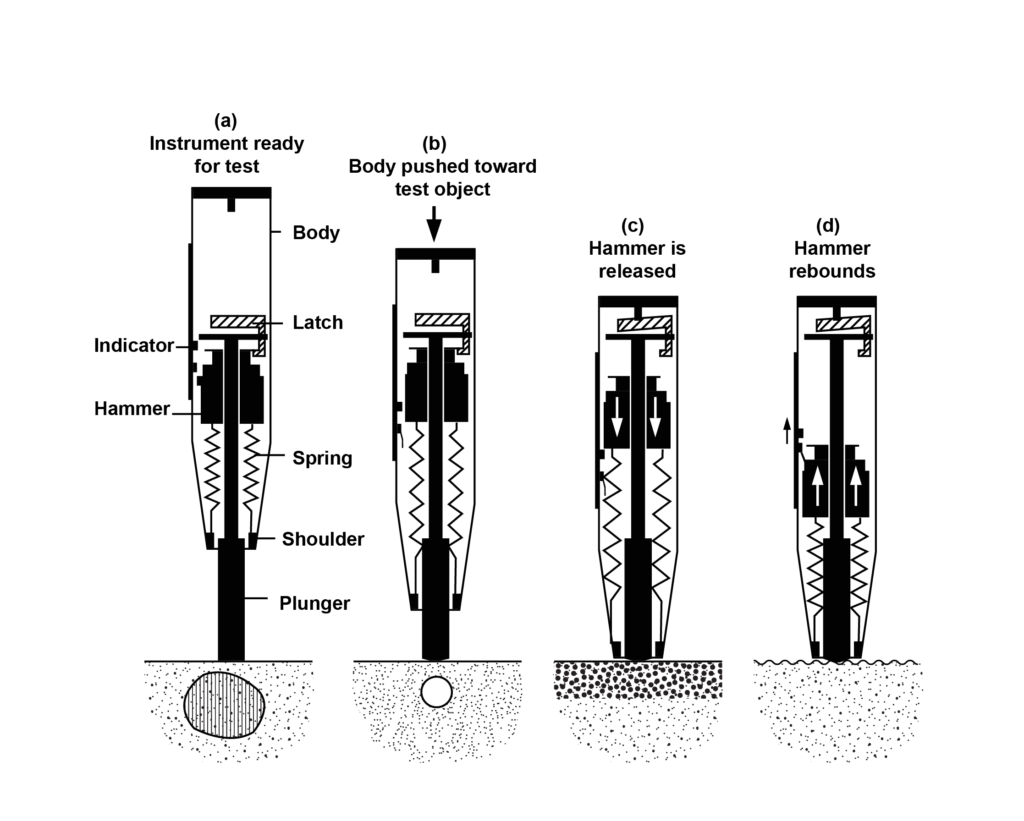

The concrete rebound hammer test (often referred to as Schmidt Hammer) was invented in 1948 and is still a popular choice to test the compressive strength of concrete. To use this method, the concrete rebound hammer must first be calibrated against a steel test anvil. Once calibrated, a spring release mechanism is used to activate a hammer which impacts a plunger to drive into the surface of the concrete. After impact, the plunger is locked in its retracted position and a rebound number is recorded (the numbers can range from 10-100). For accuracy, testers should record several numbers.

In order to establish a relationship between the rebound number and the compressive strength of concrete, experts usually use the following two methods: ACI 228.1: In Place Methods to Estimate Concrete Strength, or BS EN 13791:2019: Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components.

The Principle of the Schmidt Hammer (Concrete Rebound Hammer) Test

According to The Constructor the concrete, “rebound hammer test method is based on the principle that the rebound of an elastic mass depends on the hardness of the concrete surface against which the mass strikes.” In other words, the amount of rebound recorded using the hammer will depend on the hardness of the concrete surface, which will then correlate to the compressive strength of the concrete.

Pros of the Schmidt/Rebound Hammer Method

- The device is easy and convenient to use

- This test can be done directly onsite.

Cons of the Schmidt/Rebound Hammer Method

- This study by Sanchez and Tarranza found that the Schmidt Hammer test is influenced by a number of external factors such as moisture and temperature. They found that this test should not substitute obtaining the actual compressive strength of concrete, and that the rebound curve generally underestimates the actual compressive strength of concrete.

- You often need to use another testing method to confirm the data.

- The device itself requires regular cleaning.

- The results from the test are based on a local point.

- Before testing, the concrete surface needs preparation to be smooth, clean, and dry.

The Maturity Method

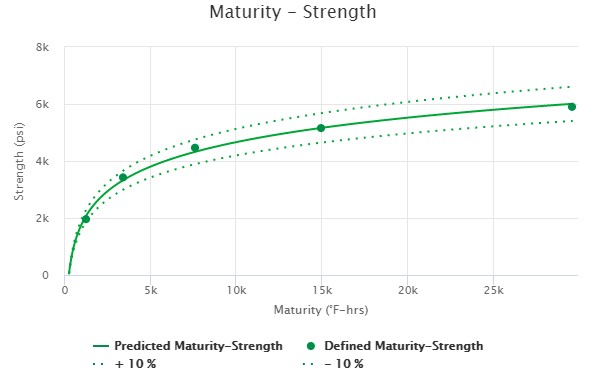

The maturity method is a non-destructive testing method that allows you to estimate the early-age and compressive strength of in-place concrete in real-time. It is defined by ASTM C1074: The Standard Practice for Estimating Concrete Strength by the Maturity Method, as “a technique for estimating concrete strength that is based on the assumption that samples of a given concrete mixture attain equal strengths if they attain equal values of the maturity index.” The maturity index value considers concrete temperature and curing time. Concrete maturity sensors like SmartRock® can be used to collect the necessary data.

Before you can use your sensors or maturity meter on-site, you must complete a calibration process. The calibration creates a unique relationship between the Maturity Index (obtained using the temperature profile) and concrete strength. A maturity calibration is necessary only once for a specific mix and its properties. This blog breaks down the entire process. Once you have calibrated your mix, you can begin your project using the maturity method.

There are many different types of concrete sensors, each with its own set of advantages and disadvantages. SmartRock sensors exist in over 8,200 jobsites worldwide and are a great choice to track maturity. These sensors have 3 easy installation steps:

- Tag your sensor. You must activate the sensor and tag it in your SmartRock mobile app.

- Install your sensor directly on the rebar, and then pour your concrete as usual.

- View your results in real-time using the SmartRock app.

The embedded sensor measures the temperature of the concrete at specific time intervals. It then calculates the concrete’s strength/maturity by using the calibration data previously inputted by the user.

The Principle of the Maturity Method

The maturity method is based on the principle that concrete strength is directly related to its hydration temperature history. ASTM C1074 outlines the most common standards. It provides the Nurse-Saul function and the Arrhenius function. The Nurse-Saul method is the more popular of the two, and it is based on the principle that there is a linear relationship between the maturity and the temperature in real time. The underlying assumption is that the strength development in concrete is a linear function of hydration temperature.

Click here for more details on the maturity method!

Pros of the Maturity Method

- The maturity method proves to be accurate and reliable, providing real-time data.

- Not only does the sensor work in any type of weather or condition, but the data can help you decide when to take measures to heat or cool your concrete. Fully embedded sensors mean no worries about onsite damages, or maintenance.

Cons of the Maturity Method

- Requires a one-time calibration for each concrete mix using cylinder break tests.

Which Method of Testing Should You Choose: Schmidt/Rebound Hammer or the Maturity Method?

Now that you have read the pros and cons of both methods, you have all the information you need to decide what you will use on your next project. You may have noticed that the rebound hammer and the maturity method have a couple of similarities. Both are non-destructive methods, which is a major advantage, but both require a calibration process, which could be inconvenient. However, the Schmidt hammer (concrete rebound hammer) method may not always be accurate. So, it is best to supplement this test with additional methods. The maturity method, on the other hand, is very accurate, and a new standard in a growing number of countries. Therefore, if you want a method that is simple to use, accurate, and works in any condition, the maturity method and wireless sensors may be the best choice for you.

Sources

American Concrete Institute

BSI

The Constructor

Reliability of Rebound Hammer Test in Concrete Compressive Strength Estimation

**Editor’s Note: This post was originally published in September 2020 and has been updated for accuracy and comprehensiveness.

2 Responses

To whom… :

Our developments and construction projects are based out of Chicago; however, we do reach to out to other select metro markets nationally. Please share what projects local to the Chicago metro area and possibly the concrete subcontractor(s) have performed their services with The Maturity Method and the respectable sensors. In addition, which concrete designs; poured-in-place, post-tension, etc.? Additionally, were test cylinders still mandated to support the data for the respective projects and did they prove out?

Thank you, Michael

Hi Michael, thank you for your comment! If you submit a demo request using this form our sales and support team will be able to answer all of your questions. Here you are: https://www.giatecscientific.com/demo/