If you’re reading this article, you’re probably getting ready to use wireless concrete maturity sensors, like SmartRock®, on your jobsite to monitor the strength of your in-situ slab. Keep reading to learn all about the concrete maturity calibration and how to apply it on site.

Here’s a Refresher on the Concrete Maturity Method

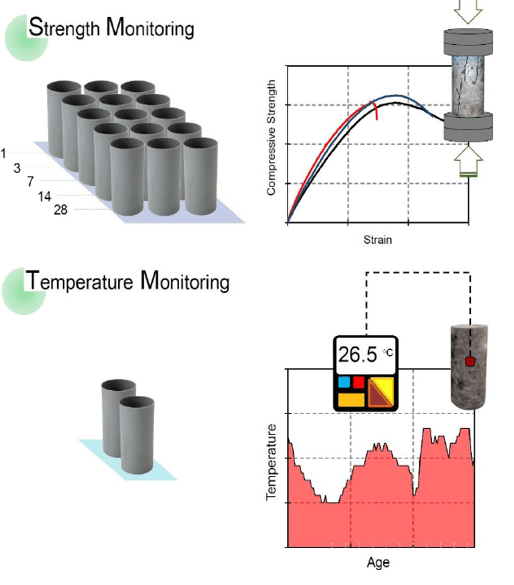

The maturity method (ASTM C1074) is a non-destructive testing approach that allows you to estimate the early-age and compressive strength of in-place concrete in real-time. The technique is based on the principle that concrete strength is directly related to its hydration temperature history. Though this methodology has been used since the 1970s, it has only recently been gaining popularity on job sites with wireless concrete maturity sensors.

The goal of these sensors is to measure the temperature of your slab in real-time and correlate this data to the concretes’ strength. Wireless sensors are placed within the concrete formwork, secured on the rebar, before pouring. Temperature data is collected by the sensor and uploaded to any smart device within an app using a wireless connection. This information is then used to calculate the compressive strength of the in-situ concrete element based on the maturity equation that is set up in the app. This information is updated every 15 minutes, meaning you will know right away when your concrete is strong enough to move on to the next steps in the construction process. This strength data is considered to be very accurate and reliable as the sensors are subject to the same curing conditions as the in-situ concrete slab. Using this method also avoids inaccuracies associated with testing labs when relying on break tests to obtain compressive strength measurements.

If you just read that summary and have no idea what we’re talking about, or just want to revisit more information on concrete maturity sensors, look at these articles:

- Make Your Construction Jobsite Safer and Faster with Smart Sensors

- Cut Down Your Project Schedule by Testing Concrete Strength On Site

- Eliminate Third-Party Lab Expenses & Cylinder Break Tests with SmartRock®

Want an even more thorough explanation of the concrete maturity method? Download our free e-book Concrete Maturity 101: From Theory to Application Here

Through all of your research on the concrete maturity method you’ve probably read a little bit about the calibration process that is required before you start using maturity sensors on site. The goal of the calibration is to associate the strength of your concrete to a maturity index that is at specific times. A maturity calibration only needs to be completed once for a specific mix and its properties. This maturity-strength relationship is developed in the lab, using cylinder break tests, and then correlated to the strength of the in-place concrete on your jobsite.

While this step may seem a little daunting, we promise you it’s not complicated. In fact, the maturity calibration can be done in 5 easy steps:

The Calibration Process Maturity Sensors On Site

- Make a minimum of 17 cylinders; 2 will be used for temperature monitoring while the other specimens will be used for compressive strength breaks. All cylinders must be cured together in a moist environment according to ASTM C511.

- Select a minimum of 5 break times, for example 1, 3, 7, 14, and 28 days. For each day, obtain the compressive strength of two cylinders, break a third cylinder if the results vary more than 10% from the average. Note the time of the breaks.

- At the time on your breaks, also obtain data from the two cylinders that were used for temperature monitoring and make an average of these values. Input these values into either the Nurse-Saul equation or the Arrhenius method according to ASTM C1074 to obtain a maturity value.

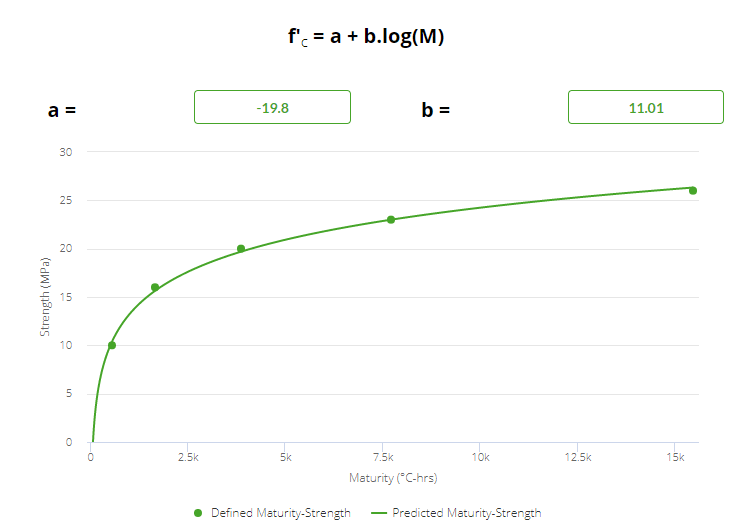

- You will now have a set of at least 5 data points each with a strength associated to a maturity value. Plotting those data points allows you to obtain a curve with a logarithm equation. Here is the formula for calculating the maturity of concrete: Strength=a+ b LOG(maturity)

- Validate your calibration curve by making a couple of additional cylinders on your next pour. Compare the calculated strength obtained from your maturity calculation to the compressive strength obtained in the lab. Up to a 10% difference is acceptable.

Take a look at this video “Real-Time Concrete Strength Monitoring – Maturity Method” for a more thorough explanation on how to perform this calibration process.

Looking for an even easier way? Try our maturity calculator here

Frequently Asked Questions About Concrete Maturity

As the maturity method increases in popularity worldwide, more standards are adopting this method. As a result, more questions are being asked about how maturity can be used for different applications and its limitations can be addressed. This section focuses on answering the questions typically asked by engineers, ready-mix producers, contractors, and testing labs regarding the maturity method and its applications.

Is the calibration still valid if there is additional water or air added to the mix?

A calibration is specific to one mixture design with specific properties. Any additional changes in materials or mixture properties would affect the strength (or rate of hydration), which would make the calibration invalid. For any change in the mixture, a new calibration should be created.

Unfortunately, it is unrealistic to assume that the exact same mixture used for calibration is used in an actual construction jobsite. It is normal that some additional water or variation in air content occurs in the mixture. For this reason, it is recommended to use concrete that is delivered to the jobsite for the calibration curve which minimizes some of these potential sources of error. Another approach would be to build the calibration curve with a mixture that still meets the specifications but with slightly higher w/cm and air content. This will, subsequently, incorporate some safety margins to the calibration.

Is the calibration still valid if retarders or accelerators are added to the mix?

The goal of the retarder is to delay the setting time. This will affect the rate of strength development by shifting the hydration to a later time. On the other hand, the goal of accelerators is to expedite the setting time and strength gain at an early age. There exists multiple types of chemical admixtures, some with or without water, reducing specifications. Retarders and accelerators can affect the compressive and flexural strength properties of the concrete specifically at an early age. For this reason, it is important that the maturity calibration be done with the accelerator or retarder incorporated into the mix. If the dosage of the chemical admixture varies from the one used during maturity calibration, a validation of this measurement is necessary and recalibration could be required. Depending on the admixtures, it’s possible that a different dosage of the admixture has only minimal effect on maturity calibration.

How long is the calibration valid for?

Technically, the calibration is valid until an element from the mix is changed. In general, validation should be done periodically, or before/during critical operations. During validation,if the differences consistently exceed 10%, a new maturity calibration needs to be developed. This is particularly essential for the general contractors who are doing the mix calibration as they do not have full control over the mixes. However, ready-mix producers who are performing maturity calibrations have better knowledge and control of their mixes.

What should be expected when comparing the results from field-cured specimens and in-place strength calculated by maturity?

One should expect a difference between the results of the cylinders and the in-place concrete. In general, the maturity method would produce higher strength results because of the larger size of the structural elements compared to concrete cylinders, which makes the process of heat dissipation slower. The in-place concrete is able to retain more heat for a longer period of time compared to the cylinders, even if the cylinders were placed under the same curing conditions. In general, the maturity method will allow you to perform critical operations faster than the break test.

It is also possible to observe the opposite effect, where the cylinders reach the required strength while the in-place elements do not. Those cases occur more frequently in cold regions or during seasons when the cylinders might have been cured in different conditions than the structural element. An interruption to the heating system or exposure to colder temperatures would make the structural element cure slower compared to the cylinders.

Editor’s Note: This post was originally published in November 2017 and has been updated for accuracy and comprehensivenest

4 Responses

That’s interesting that concrete maturity is determined by their strength and the temperature. This is good to do since you wouldn’t want to use concrete on a building that could break later on. It would also be good to use on concrete cylinders used for light posts since it would be best to have that strong as well so a car can’t destroy it and the light during an accident.

Why would you ever want to “estimate strength” testing with so many variables?

Compressive or destructive testing is representative testing…not an estimation.

Unless you can guarantee that the water to cement ratio is accurate at the locations of the sensors then all is good…at that sensor.

I’d prefer testing multiple locations and perhaps achieving a usable average.

This product should be marketed as a way to save time on the negative items mentioned for destructive testing such as breaking lab tests too early because of cold temps etc.

Hi Mark,

The primary issue with determining strength of cylinders is that the temperature history of that cylinder may significantly differ from that of the actual structure. This is quite significant for elements with relatively large dimensions. Such elements can retain the heat produced during hydration for prolonged periods of time. On the other hand, due to the small volume and the large surface area of the cylinders, the heat is dissipated rather quickly compared to the actual element. This generally leads to the cylinders having lower compressive strength than the element under consideration. Therefore, it can not just be stated that “Compressive or destructive testing is representative testing”; because it is not representative for every case.

Due to the accuracy of the method, ASTM allows it (in the ASTM C1074 standard) to be used for critical activities such as: (1) removal of formwork and reshoring; (2) post-tensioning of tendons; (3) termination of cold weather protection; and (4) opening of roadways to traffic.

We certainly agree that you need to test multiple locations and achieve an average and this is generally recommended by us. Getting a specific maturity index at one location does not guarantee conformity at other locations (just like cylinders). This can also be used to determine if the concrete used for different location has the same mix design and composition (can be determined from the temperature history as well).

Its great work to add step of validation for calibration maturity curve (step number 5) especially in next poor stage…

Again many thanks to R&D department giatec represented in Ms Sarah De Carufel…

Regard