Summer is a busy time for the construction industry. The warm months present a chance to get a lot done, and avoid the extensive challenges that come with cold weather concreting. However, hot weather concreting can also affect the safety and durability of your structure if you do not take measures for concrete cooling in summer. Since the temperature of your in-situ concrete during hot weather directly affects its strength development, here we share five tips that will help you these summer months.

Why Is Concrete Cooling in Summer Important?

ACI defines hot weather concreting as “one or a combination of the following conditions that tends to impair the quality of freshly mixed or hardened concrete by accelerating the rate of moisture loss and rate of cement hydration, or otherwise causing detrimental results: high ambient temperature; high concrete temperature; low relative humidity; and high wind speed.”

When hot weather concreting, there may be serious consequences that can be irreparable under drastic temperatures. Your structure can lose durability if the temperature during hydration is too high due to an early peak in strength gain. One risk you may encounter during hot weather concreting is concrete shrinkage. Shrinkage may be defined as “the reduction of concrete volume due to the loss of moisture” (The Constructor). This problem occurs when concrete loses moisture after it has hardened, and it can cause cracks and create an unsafe structure.

5 Tips for Hot Weather Concreting

There are a variety of methods and tools for concrete cooling in summer. Here are some tips to keep in mind:

- Keep coarse aggregates cool by storing them in the shade or with mist,

- Use cold mixing water,

- Substitute some water with ice,

- Cool down the cement – cement is stocked in silos, and often retains high temperatures from the factory,

- Pour concrete at night/outside of peak temperatures.

Learn more about monitoring curing temperatures in hot and cold weather here!

The Giatec Solution for Hot Weather Concreting

The temperature of your concrete is not the same as the ambient temperature. Factors like humidity, hot weather, and wind can also impact the curing process. When concreting in hot weather, you want to keep the temperature of your concrete under 160°F (70°C). For this reason, finding a solution to accurately monitor the temperature of your placed concrete and choosing the right web concrete monitoring device is very important.

SmartRock®

The easiest way to track the changing temperatures when concrete cooling in summer! The sensors are fully embedded and easy to implement and highly reliable, logging internal temperatures every 15 minutes. With real-time data, you can make the right curing decisions for your structure. Gilchrist Construction Company utilized SmartRock sensors on a major bridge construction project, helping them shorten their timeline by 4 months! They began their project in March and were able to open the bridge by October of the same year. The sensors helped them consistently monitor concrete temperatures throughout hot weather months while reducing the amount of needed labor and break tests.

Read the full Gilchrist Construction case study!

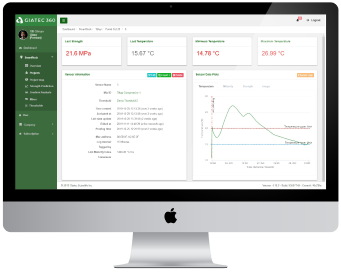

Giatec 360™: Cloud-Based Dashboard

To further improve efficiency, you can use Giatec 360, the world’s most advanced web-based dashboard for controlling and predicting the quality of concrete pours. This platform is an extension of the SmartRock app, and it allows you to plot data between multiple sensors, edit your mix calibration data, generate PDF/CSV reports for distribution, and monitor multiple projects at once. This includes temperature gradient analysis of mass pours. By implementing these technologies into your project this summer, you can achieve more with less time.

SmartHub™

Finally, by adding SmartHub you will be able to access all of the data from the SmartRock sensors, without actually being present on the jobsite. This can be a huge game changer, particularly if the jobsite is in an inconvenient location. In addition to this, SmartHub’s alert system will work with our Artificial Intelligence assistant, Roxi™, to provide you with smart notifications when your concrete reaches certain temperature or strength thresholds. This will allow your team to move through the project quickly, but it will also keep your jobsite safe by notifying you of critical problems as soon as they occur.

Implementing the full Giatec Solution will help you finish your project faster and with less stress – so you can actually enjoy those summer months on and off the jobsite.

Sources

**Editor’s Note: This post was originally published on June 2020 and has been updated for accuracy and comprehensiveness on June 14th, 2023.