According to ASTM C125 – 20: Standard Terminology Relating to Concrete and Concrete Aggregates, the concrete setting is “the process, due to chemical reactions, occurring after the addition of mixing water, that results in a gradual development of rigidity of a cementitious mixture.”

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

In other words, the concrete undergoes a process called hydration, in which the major compounds in cement form chemical bonds with water molecules. Hydration causes concrete to harden and become durable enough for its intended use. The setting period begins when the concrete is placed and continues until it has developed the desired properties.

Depending on the specific application for which the concrete will be used, it should have a relative humidity of more than 80% and a temperature of more than 10°C (50°F) for 3 to 14 days. This can be tested using a concrete setting sensor.

The setting has a significant impact on the properties of hardened concrete including:

- Strength

- Permeability

- Abrasion resistance

- Volume stability

- Propensity for early-age cracking

- Resistance to freezing and thawing and de-icing chemicals

The Impact of Weather on Concrete Setting

Construction projects would be much easier to complete if they were subject to perfect weather conditions for pouring and setting all year round. The reality is, contractors, engineers and project managers have to adapt to different weather conditions in order to build structurally sound concrete structures. When extreme weather conditions are present, it is essential to monitor the temperature of your concrete in order to avoid damaging the structural integrity.

In the American Concrete Institute (ACI) 306: Guide to Cold Weather Concreting, “cold weather” is defined as three or more consecutive days of low temperatures, specifically outdoor temperatures below 40°F (4°C) and air temperature below 50°F (10°C) for more than any 12-hour period. If the ambient temperature is too low, the hydration of the cement will drastically slow down or completely stop.

Cold weather slows down the setting process or stops it completely, negatively impacting the concrete’s strength gain. Furthermore, if it sets while being exposed to freezing temperatures, the water in the concrete will freeze and cause it to crack, significantly reducing its durability and the service life of the structure.

Hot weather concreting is no exception and poses risks to damaging your concrete as well. High temperatures lead to rapid water evaporation, and as a result, higher early strengths. Higher early strengths create less durable structures over the long term and compromise the structural integrity of your concrete. The concrete will experience a reduction in strength gain and potentially crack. However, the cause in this case is rapid water evaporation.

Click to learn more about concrete temperature during extreme weather!

How Mix Design Affects Concrete Setting

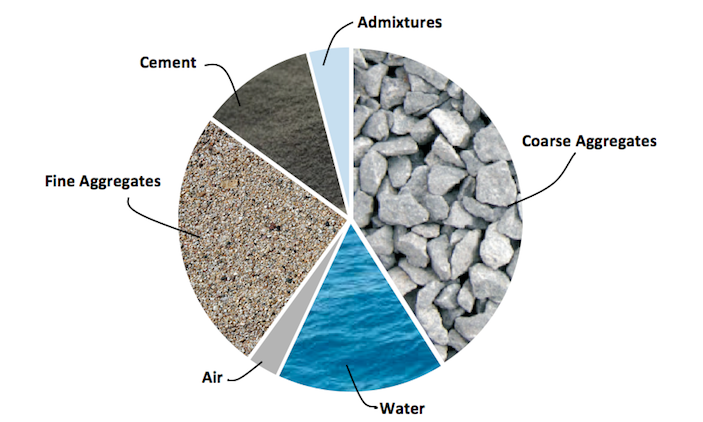

Your concrete’s mix design is composed of cement, coarse aggregates, fine aggregates, admixtures, water and air. Each of these elements plays a huge part in setting. Here are a few tips for your concrete mix design that will optimize your concrete setting:

- Using larger coarse aggregates is more economical as it reduces the amount of cement per unit of volume, but it may cause issues with the workability of the mix.

- A lower water/cement ratio will increase the strength of the concrete and provide better durability. However, it can also significantly reduce the workability of the concrete.

- When a concrete structure is exposed to freezing or de-icing salts, increased air content will increase concrete durability because it allows the water to expand in the entrapped air when it freezes.

- Using pozzolanic material, such as fly ash, silica fumes, or slag, to replace a portion of the cement is more ecological and economical. Typically, it slows down the setting process and provides enhanced properties to the concrete.

Concrete mix design is an essential part of your concrete project. Finding the right combination of elements will ensure you optimize your concrete mix giving your structure strength, durability, workability and other desirable properties. Giatec’s SmartMix ™ software is a web dashboard that enables producers to optimize concrete materials and predict the performance of their mixes. With the SmartMix dashboard, producers can adjust the proportions of their concrete mixes, such as the use of chemical admixtures and amount of cement. With the help of Roxi ™ (an artificial intelligence program), the dashboard’s suggestions ensure that these adjustments will meet a mix’s designed compressive strength and other performance criteria.

Click here to learn more about concrete mix design optimization!

How to Test Concrete Setting

Testing and monitoring the temperature of your concrete using the appropriate web concrete monitoring device throughout the setting process is essential to your construction project. There are many ways to do this, one of the most efficient ways being utilizing the maturity method and a concrete setting sensor!

The maturity method is an accurate and non-destructive way to measure the cumulative effect of time and temperature on concrete properties and thereby allows for the estimation of the strength of in-place concrete. Application of the maturity method requires monitoring in-situ concrete temperature in a structure over time and calculating the effect that time-temperature history has on the maturity of the in-situ concrete.

Using a concrete setting sensor like SmartRockTM allows you to collect the required data accurately and in real-time without having to employ more costly and time-consuming methods. Simply install it directly onto the rebar without cumbersome wires or expensive data loggers. Once the concrete is poured and set, temperature and strength readings are immediately sent to the mobile app for viewing.

To give you more power on the job site, you can even use SmartHub™, a remote monitoring system, to access SmartRock sensor data, anywhere, anytime. It automatically collects data about your concrete so you can analyze it without even having to be physically on the job site.

With SmartRock being installed in over 8,000 job sites worldwide, wireless sensors are quickly becoming the preferred method to measure concrete setting due to their cost-savings over the long-term and optimization project schedules.

**Editor’s Note: This post was originally published on August 21, 2020 and has been updated for accuracy and comprehensiveness.