Controlling the temperature of concrete on construction sites poses many challenges. It is critical to keep track of your concrete temperature differential to ensure the optimal quality of concrete. It is also important because improper temperature measurement can lead to failed structures, increased project prices, and longer completion timelines. On-site temperature measurement can be tricky and although there are multiple options for temperature measurement, not all are created equal. This article will give an overview of what the ASTM covers and the challenges for on-site concrete temperature measurements.

Download the full Checklist now and experience smoother, stress-free cold-weather concreting like never before.

Why Measure Concrete Temperature Differential On Site

Failing to properly measure concrete temperature can gravely compromise the strength development and the hydration process of your concrete element. If concrete is exposed to temperatures too high or too low or the temperature differential is too high, your mix will not gain strength as intended and you run the risk of developing thermal cracking. Measuring concrete temperature on site gives you a more accurate representation of strength gain than off-site strength testing. Monitoring concrete temperature throughout the curing process will allow you to ensure proper strength gain and to be confident in the quality of your element and its durability.

How to Measure Temperature?

The American Standard Testing Method (ASTM) for concrete temperature outlines different methods of measuring concrete temperature on site. Two of the most popular methods for testing concrete temperature on site are wireless and wired concrete sensors or thermocouples. While both sensors can provide you with accurate concrete temperature data throughout the curing process, both present their own sets of pros and cons.

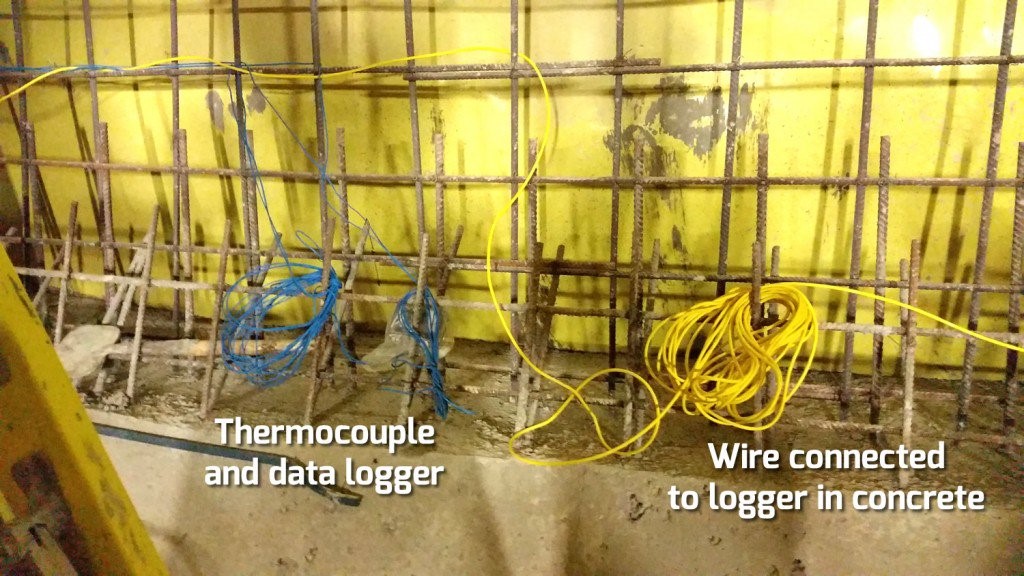

Challenges of Thermocouples

Although thermocouples are widely used on construction sites around the world, they present many challenges and opportunities for errors that could drastically jeopardize the integrity of your concrete structure. The first challenge with hard-wired sensors is the wire itself. In order to ensure accurate data everyone on the jobsite must be aware and mindful not to damage or lose wires protruding from the concrete. Secondly, traditionally wired sensors do not store or gather data automatically. Project managers must carry expensive equipment that is at risk of failure or damage and connect individually to each sensor to gather data at specified time intervals. The data gathered from these devices must be handled with care and it is only stored in the device itself and does not have a backup. These reasons among others, are why newer generations of project managers are opting for wireless concrete sensors over wired sensors.

The Most Reliable Tool for ASTM Concrete Temperature Measurement

With advanced tools like SmartRock®, monitoring the concrete temperature on site quickly and accurately has never been simpler. SmartRock is the most reliable tool to ensure that you know the exact temperature of your concrete at any time. The fully embedded sensor eliminates the aforementioned challenges as there are no protruding elements at risk of being damaged. With proper installation and activation, SmartRock measures concrete temperature every 15 minutes. It also stores the data on its built-in memory until it is easily retrieved by any smart device.