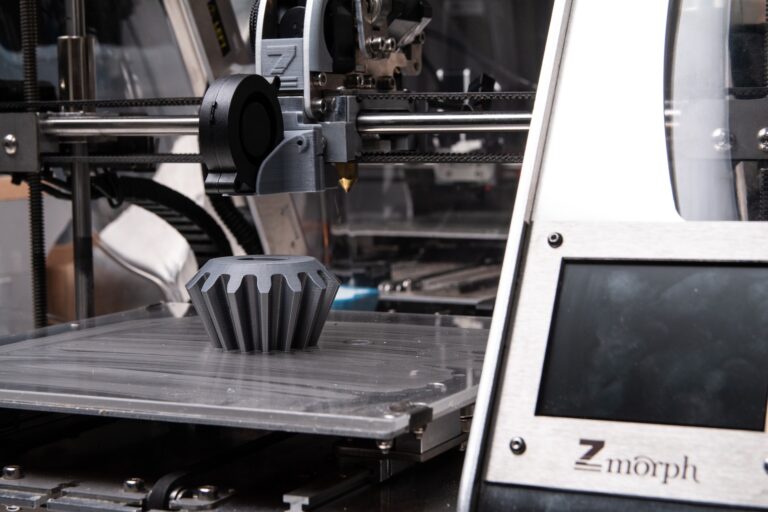

Recently, we discussed how the use of 3D printers at construction jobsites may soon become common practice. Advances in 3D-printing technologies have resulted in the ability to craft anything from chocolate and food to statues and even entire buildings.

Download the full Checklist now and experience smoother, stress-free cold-weather concreting like never before.

Considering the competitive nature of the construction industry, 3D printing offers contractors an innovative way to set themselves apart from their competitors. To prove this point, here are eight advantages that using a 3D printer could give to the construction field.

1. Reduced Injury

One of the biggest benefits that 3D printers have presented to construction workers is a reduction in injuries in the field. Considering that building with concrete is difficult—even dangerous—this is a welcome improvement. Not only do workers have an easier time doing their job, but employers have less worker’s compensation paperwork to wade through due to injuries on the job.

2. Reduced Material Costs

Photo credit: L&S Waste

Another improvement is a considerable reduction of material waste. 3D printers use the exact amount of concrete needed for the wall, floor, or whatever it is that you want to build. Builders and GCs don’t have to order in bulk because they’ll know exactly how much material they need. Not only is this a more sustainable, environmentally friendly way to build, but it also results in reduce costs for the contractor.

3. Quicker Construction

This is where concrete 3D printers truly set themselves apart from traditional construction methods. Where a project may sometimes take weeks–or months—to complete, 3D printers can often finish a project in a matter of hours or days. An entire house was once constructed in 24 hours! This allows contractors to move onto other projects sooner…and with more orders filled, more money is brought in for the contractor.

4. New Markets

Using a 3D printer also allows construction companies to work in markets that might have otherwise been inaccessible to them before. And for new construction companies, having a 3D printer on hand could set them apart from companies that have been around for a few decades and are resistant to change.

Similarly, traditional and established construction companies could utilize 3D printers to make sure they remain relevant in the market. Essentially, 3D printers can be used as a means to enter a new market but also to give an already established company a competitive edge.

5. Cheaper?Construction

Overall, the use of 3D printers costs less than traditional construction techniques and processes. With the reduction of injuries, time, and material cost, companies will see a dramatic increase in their profits. And while some workers will probably have to be let go, others will remain, since someone still needs to be able to put all of the pieces together. By learning the technology, workers have a chance to maintain their job security as well. They’ll earn more, as will the company as a whole.

6. Improved Form

3D printers are renowned for their ability to create seemingly odd and atypical design structures. Now construction companies can utilize that to offer their clients unique buildings designed entirely for them. This can open up their portfolio to certain individuals who may not want the standard rectangular options.

Essentially, being able to create unique architectural designs for a client makes the construction company more desirable to certain clients.

7. Better Durability

While testing concrete during the early stages of construction will continue to be necessary, 3D printers have been found to contribute to the durability of the structural elements. This is due in part to how the materials are made and the manner in which they are assembled. More durable buildings mean fewer repairs need to be made, so construction companies can focus their efforts elsewhere to drive profit. For clients, too, their preferences certainly rest with a building that will last longer.

8. Brand Improvement

Finally, one of the most important impacts that the 3D printer has had—and will continue to have—on the construction industry is increased brand awareness. Construction companies are typically thought of to be wasteful and unsustainable (save for those companies who make it their business to utilize green processes, of course).

Because it reduces waste, 3D printing is an excellent method for a company to improve how they are viewed by those who are concerned about the environmental toll that concrete construction takes on the world. Contractors that could use a little help in their branding could do well to procure and utilize a 3D printer.

Read about other ways to differentiate construction business.

These reasons (and many more) make it obvious why 3D printing can and has helped the construction industry move towards a cleaner, brighter future.

Feature image photo credit: All3dp.com

Author biography

Mohamed Bah handles online media relations for Mecsoft Corporation , and in his spare time, he enjoys swimming, traveling, basketball, and playing with his puppy, Leo. He also volunteers in his local community because he believes in showing kindness to everyone.

5 Responses

Thanks for sharing your thoughts about 3d printing companies in nigeria.

Regards

Hi! I’ve been reading your website for a while

now and finally got the bravery to go ahead and give

you a shout out from Lubbock Texas! Just wanted to mention keep

up the fantastic job!

Incredible points. Great arguments. Keep up the great work.

Hi to every one, the contents present at this web site are actually awesome for people experience,

well, keep up the good work fellows.

Dear friend,

Would you please tell me what are the panels you used in the picture above for the roof.

Thank you, Gil