One of our top priorities at Giatec is helping our customers and partners find an environmentally friendly way of building with green concrete. It is no secret that concrete, particularly the cement in a concrete mix, can have a negative impact on the environment due to the CO₂ it produces. There are two reasons for this. First, without cement, concrete cannot be produced as it is the binder of the mix. Second, manufacturing cement produces CO₂ due to fuel burn which keeps the kiln operating because of the calcination process. For every kilogram of cement produced, .81 kilograms of CO₂ is emitted.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Although there are plenty of reasons why green concrete is still an excellent choice for building materials, we want to show you how to improve your concrete construction projects.

What Makes Environmentally Friendly Concrete?

To start, let’s consider what makes a project environmentally friendly. There is no standard definition for this, it is really up to the company in charge to use the available alternatives and practices that will reduce waste and improve sustainability. This blog will explore some of those options. If you want to take your project to the next step in sustainability, you can seek Leadership in Energy and Environmental Design Standards (LEED) certification. You can proudly say that an independent party has verified that your structure “was designed and built using strategies aimed at achieving high performance in key areas of human and environmental health: location and transportation, sustainable site development, water savings, energy efficiency, materials selection, and indoor environmental quality” (Canada Green Building Council).

Click here for FAQs on Sustainable Concrete!

Save CO₂ Emissions with Roxi™

To make your project eco-friendly, start by checking with your producer whether the green concrete mix can be optimized. The supplementary cementitious materials (SCMs) and checking the mix performance allow evaluating if cement content can be reduced. One added bonus to SCMs is that they are often by-products of other industries, so you will be utilizing a material that would have otherwise gone to waste. An example of a common option is fly ash, which is a by-product of coal-fired electric and steam-generating plants. Furthermore, as concrete will always be locally produced, you can ask your producer about green concrete options available within your region and select materials that will bring less impact to the environment.

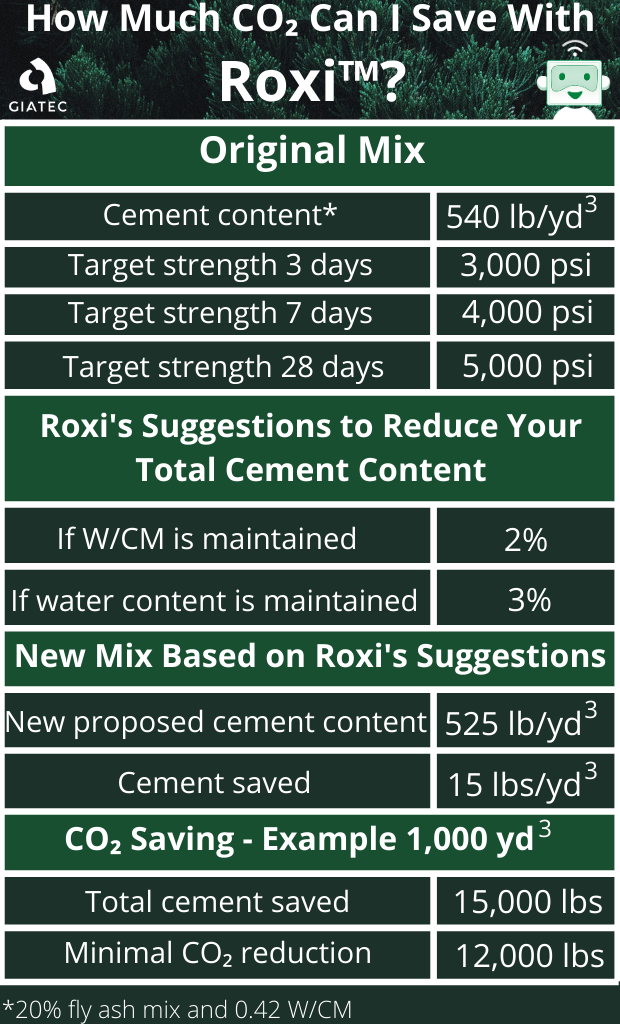

This is where our AI assistant, Roxi™, comes in. Roxi works with SmartRock® wireless sensors, which gives the program access to millions of data points to analyze and learn from. When creating a mix design, there is often not enough visibility into the rate at which the concrete will harden in different conditions. As a result, producers may add more cement than necessary to the mixes. Roxi has been trained with the help of funding from Sustainable Development Technology Canada (SDTC) to suggest the amount of cement that can be removed without compromising the concrete’s setting time or strength development.

The following table shows examples of how much CO₂ Roxi can save, depending on the size of the project.

Click here to learn more about Roxi!

6 More Ways You Can Make Environmentally Friendly Concrete

1. Try CarbonCure’s Solution

CarbonCure works with concrete producers to create more sustainable concrete. Their unique technology injects CO₂ from industrial emitters into concrete, where the CO₂ then becomes chemically converted into a mineral. The mineralized CO₂ improves concrete performance and compressive strength, making it a safe and sustainable option.

2. Use a Lightweight Concrete Mix

Lightweight concrete has a different composition than a regular concrete mix has. Simply put, the mix uses lightweight coarse aggregates to give it a low density and a high strength. Lightweight Concrete Solutions in Ontario create high-quality concrete that can achieve desired strength in as little as 7 days or less! What’s more, they use recycled content and natural materials, which helps reduce CO₂ emissions and energy consumption on your project. It’s a win-win solution!

3. Use Recycled Concrete

When an old concrete building is demolished, it has the potential to create a lot of waste. However, recycling concrete is now an easy and well-researched process. The old, large pieces of concrete can be broken down into coarse aggregates, as shown in the video below.

These recycled coarse aggregates can then be used in your mix design, instead of using entirely virgin aggregates. If natural sand is used, up to 30% crushed coarse aggregate can be replaced with coarse recycled aggregate. By using recycled concrete in your mix design, you can reduce the number of building materials in landfills and reduce the impact of extracting entirely new aggregates (Portland Cement Association).

4. Source Materials Locally

When it comes to sourcing your building materials, put some research into your supplier. Here are some recommendations from Building Green:

- If possible, choose a local supplier so there is less environmental impact from transportation.

- If there are no local options, look for companies that have transport via rail or ship, as those methods emit fewer CO₂ than a truck.

- Remember that frequent, short trips can have a huge impact. Try to reduce the number of trips you are taking to pick up supplies by purchasing multiple materials from the same company or by picking up all of your supplies from a similar area.

Clearly, there are a lot of variables to consider. Ultimately, the best option will depend on your unique project needs and location.

5. Return Fresh Concrete

Instead of sending leftover fresh concrete to landfills, contractors can send it back to the manufacturer to be re-used in a new batch of ready-mix concrete. The ASTM C1798: Standard Specification for Returned Fresh Concrete for Use in a New Batch of Ready-Mixed Concrete specifies how the materials should be measured, verified, and used. By participating in this process, you can stop usable concrete from going into a landfill. One thing to keep in mind with this process is that the fresh concrete is usually only usable for 90 minutes (ASTM C94: Standard Specification for Ready-Mixed Concrete). In order to help your concrete producer, be sure to have a plan that is quick and efficient so that you can take any leftover fresh concrete directly back to the manufacturer. This is a great way to make concrete construction more environmentally friendly.

6. Create Buildings That Last

One of the best properties of concrete is its long service life. A well-built concrete building has the potential for restoration and repurposing rather than destruction. Before beginning your project, ask yourself the following questions: Will it need to handle extreme weather conditions? How will I make sure my concrete element cures properly? What method will I use to test the durability of my concrete? Plan ahead so your structure will be safe and long-lasting!

One way to improve the durability of your structure is to use a wireless maturity sensor like SmartRock®. This will allow you to monitor your concrete’s temperature and strength in real-time. Furthermore, the SmartRock system will allow you to monitor the in-place strength, rather than only concrete samples. This will bring peace of mind when performing critical operations, knowing that your concrete has attained enough strength to withhold the tensions from service life, avoiding detrimental actions, and improving the durability. Today, over 9,000 projects worldwide trust SmartRock!

Do you have any tips for a more environmentally friendly concrete construction project? Let us know in the comments!

**Editor’s Note: This post was originally published on November 2020 and has been updated for accuracy and comprehensiveness on May 2022.

Sources

CarbonCure