How Does Concrete Impact the Environment?

You have probably noticed that we are big fans of concrete here at Giatec. It is an amazing, durable, and cost-effective material used around the world. In fact, concrete is the second most used material after water! Still, we are aware that no building material is perfect, and it is becoming increasingly important to understand how concrete contributes to important issues like climate change. In this blog, learn all about sustainable concrete and how it revolutionizes the concrete industry.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

One of the most important elements in a concrete mix design is cement. When mixed with water, this ingredient binds the mix and allows concrete to set, harden, and gain strength. However, there is one problem with the production of this essential element: it emits CO₂. Cement is produced with limestone, which must be heated at a high temperature (around 2,700 °F or 1,500 °C). The heating process “causes the limestone to chemically decompose, leaving behind a compound called calcium oxide, which is used in the final cement product, releasing carbon dioxide gas into the atmosphere” according to this Scientific American article. As the global population and urbanization grow, so does cement production. Today, the process is responsible for around 8% of global CO₂ emissions (World Economic Forum). To visualize the impact in another way, for every kilogram of cement produced, .81 kilograms of CO₂ is emitted.

Testing is Key

Testing concrete strength is mandatory for concrete construction. Without these tests, there are risks of concrete cracks and loss of structural integrity, which can reduce the service life of a building. Concrete cylinder break tests have been the traditional method in the construction industry for many years. This method tests field-cured or standard-cured cylinders by placing the samples in a hydraulic compression testing machine and allowing the machine to compress the sample until it splinters or breaks. The problem with this is clear: it produces a lot of concrete waste. It also usually requires trips to a lab, further adding to the project’s environmental impact. You can click here to read more about this process.

You might be thinking this is a hopeless issue, but do not worry, it’s definitely not! There are a number of solutions that are beginning to materialize, making concrete much safer for the environment.

What is Sustainable Concrete?

There are a few different ideas about how we can create more sustainable concrete. Sustainable concrete construction should have a minimal total environmental impact, and be durable. In 1987, the Brundtland Commission Report defined sustainability as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

One solution is to increasingly replace the portion of cement with supplementary cementitious materials (SCMs). These materials are often already in your concrete mix and may include fly ash, slag cement, and silica fume. It is important to make use of these materials, as they are by-products from other industries that may otherwise go to waste. By replacing more of your cement with SCMs, you can reduce the overall amount of cement in a mix. Therefore, this reduces the level of CO₂ emissions. In addition to the sustainability benefits, these unique materials can improve workability, flexural and compressive strength, resistance to chlorides and sulfates, and decreased permeability (Lafarge). However, one drawback to using SCMs is that it can slow down your setting time and strength gain of the concrete element (ASCC Education, Research & Development Foundation).

The Importance of Research

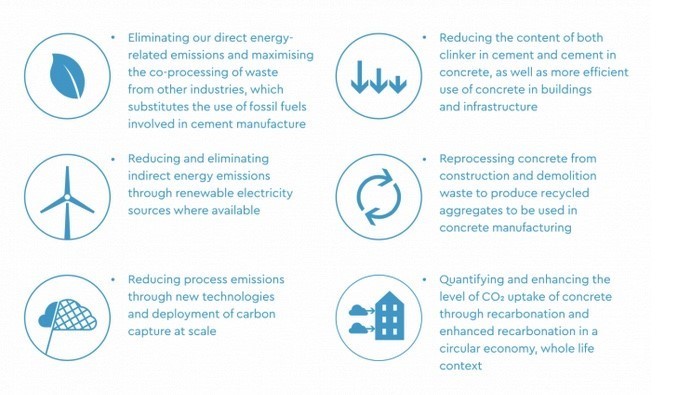

In order to achieve sustainable concrete, we need research, awareness, and the companies that use or produce cement need to work towards the same goal. One organization that is helping the cause is the Global Cement and Concrete Association (GCCA). They have an impressive goal of delivering society carbon-neutral concrete by 2050. Over the past 20 years, they have already achieved a 19.2% reduction in CO₂ emissions per tonne of cementitious material. Here’s how they will continue to work towards carbon-neutral concrete:

Finally, it is important to remember that concrete already has sustainable properties, especially when compared to other building materials. Here are just a few benefits of concrete to keep in mind:

- Excellent thermal insulation properties, which reduce electricity and heat production.

- Long service life. This means that buildings can be restored and repurposed instead of being torn down and rebuilt.

- Concrete mixes use industrial waste like fly ash, which is a by-product of coal production. These materials may end up going to waste otherwise.

- It naturally absorbs carbon dioxide over the course of its (long) service life (Scientific American).

These benefits show that concrete is still a very valuable material, even in terms of sustainability. It is also important to note that there is no other option available to meet the requirements and demand for building material. Click here for more information about the benefits of concrete!

How Does Giatec Make Concrete More Sustainable?

Now that you have an idea of how concrete impacts the environment and what can be done to help, you may be wondering what our team is doing to make concrete environmentally friendly. Here at Giatec, we are passionate about fighting climate change, this issue drives the development of our products.

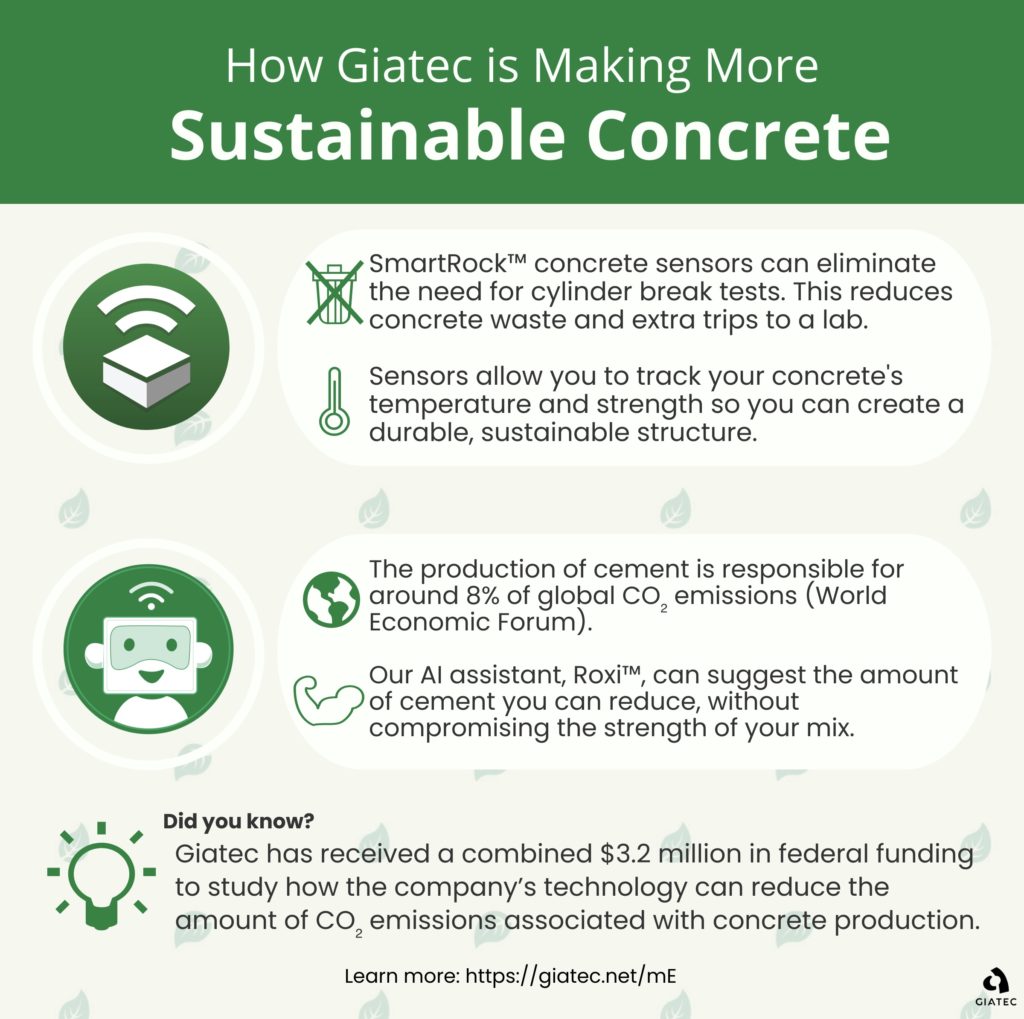

First, the ability to monitor your concrete’s temperature and strength with SmartRock® sensors and the maturity method can eliminate the need for concrete cylinder break tests, significantly reducing concrete waste. You can get the data from the sensors directly on the jobsite, which also eliminates those frequent trips to the lab. In addition, the sensors can help confirm your concrete is at a safe temperature and gaining strength properly, ensuring a long-lasting structure.

Furthermore, our assistant, Roxi™, is the first artificial intelligence program with the ability to evaluate mix designs. Not only can Roxi detect potential errors in your maturity calibration based on your mix design, but it can also analyze and suggest the amount of cement you can reduce, without compromising the strength of your mix. Typically, concrete mixes are over-designed and use more cement than necessary. With Roxi, you can optimize this process by reducing the amount of cement in your mix without any adverse effects on your concrete’s strength requirements.

Revolutionizing the Industry

These are just a few ways we are helping our partners, clients, and customers improve the sustainability of their concrete. To support our research and development, we have received funding of $2.4 million as part of a $58.6 million investment in 14 Canadian clean technology companies. These projects are being funded through Sustainable Development Technology Canada (SDTC), which works with Canadian companies to bring clean technologies to market. Funding of $800,000 was also received from the National Research Council of Canada Industrial Research Assistance Program (NRC IRAP) to support the research and development of artificial intelligence (AI) applications for a predictive concrete analysis.

Sustainable concrete is a major part of our vision to revolutionize the concrete industry, and our team will continue to work hard to reach this goal!

**Editor’s Note: This post was originally published in October 2020 and was updated for accuracy and comprehensiveness in June 2022.

Sources

Cement and concrete as an engineering material: An historic appraisal and case study analysis