A Viable Alternative to Corrosion Causing Road Salt

In Canada and other parts of the world with colder climates, road salt has been used for decades to ease the effects of ice on roads and prevent slipping and traffic collisions. Although salt is effective for melting ice and absorbing moisture similarly to how a towel or sponge would, it is just as effective at damaging concrete roads.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Road Salt and Concrete Corrosion

Sodium chloride for deicing roads is used in granular form or in a brine spray and is extremely damaging to roads made of concrete. It works by lowering the freezing/melting point of water, which results in leaving roads covered in the salty slush we are all too familiar with here in Canada. Although de-icing with salt is effective on most days, it becomes almost completely ineffective as temperatures drop below -20 C as it turns back into ice.

The buildup from ice not only makes it harder to store removed snow since it contains a high amount of sodium chloride and can’t be as easily discarded, it is also damaging to equipment, vehicles, road surfaces, concrete, and aquifers.

Because the salt does not evaporate like moisture, it gets dispersed through melted water, turns into airborne droplets as it gets kicked up by traffic, or remains on the roads after spring has come and snow and ice are no longer a problem. The salt that has been dispersed continues to cause damage to the environment just as the salt that remains continues to cause damage to roads and concrete structures.

As corrosive chloride ions penetrate into the pores of concrete and reach the metal reinforcement, they start the process of corrosion which lasts months or years and worsens with time until the structure is rebuilt. Although this process is nearly unavoidable, salt brine seeping into the concrete is responsible for dramatically speeding up the process. In Canada alone, the use of road salt is responsible for many bridge and structure failures including the collapse of the De La Concorde Bridge in Laval, Quebec and the Algo Center Mall in Elliot Lake, Ontario.

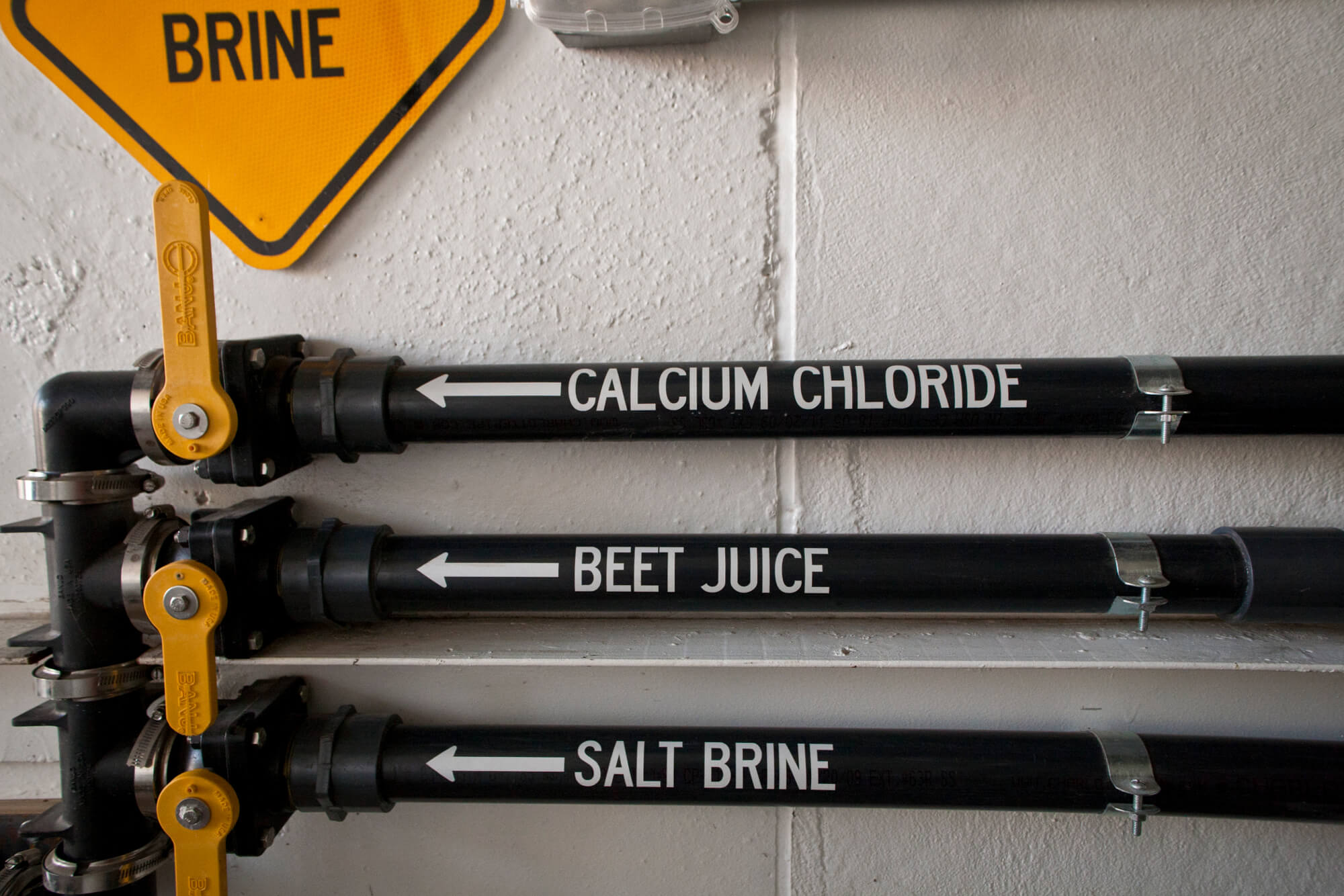

The Introduction of Beet Juice

For years engineers have been working to find ways to counteract the reaction caused by road salt on concrete and have developed new recipes for concrete that contain less calcium hydroxide meaning they produce less of a damaging chemical reaction. They have also been working to find alternatives to road salt which cause less damage to the environment, population, and infrastructure. One of the newer ingredients they’ve started using is beet juice—yes, like the root vegetable.

In December 2017, the city of Calgary started using a mixture of salt and beet juice to de-ice roads. Other cities such as Laval and Cowansville in Quebec, and Toronto in Ontario have used their own mixtures of beet juice and salt. This mixture is not only more eco-friendly, causing less damage to the environment, infrastructure, and personal property, but is also more cost effective.

How it Works

As mentioned above, salt is used as a de-icer due to its ability to lower the freezing point of water surrounding it. As ice has a thin film of liquid water on its surface, when salt comes into contact and mixes with that liquid, it raises the temperature by lowering its freezing point and causes surrounding ice to melt, then creating a chain effect. Increasing the salt concentration causes this process to become even more effective as a higher concentration of salt reduces the water molecules’ ability to come together and form ice.

Salt, or sodium chloride, isn’t the only molecule capable of causing such a disruption that ice crystals can’t form. The sugar molecules from beet juice cause a similar reaction. When beet juice is mixed with the salt solution used for de-icing, it can lower the melting point even further. The Canadian cities mentioned above have started to mix a waste byproduct of the beet sugar refining process called beet molasses with traditional de-icing solutions mainly containing salt. This has allowed them to reproduce the same effects of ice melting while drastically cutting down on the concentration of salt necessary for doing so. The use of the beet molasses is not only more effective than the use of beet juice as the stickiness helps bond the salt to the road surface, but the fact that beet molasses is generally discarded after the sugar production process means this method could also be beneficial for waste reduction.

A Viable Solution?

It would be impossible to find a solution to road salt that comes with zero downsides. In 2014, National Geographic reported that run off from this sugary beet solution can end up in streams where it attracts higher levels of bacteria, which in turn depletes the oxygen supply in the water and is problematic to the animals that rely on it.

Another downside is one you might have asked yourself about while reading this article. Yes, the beet juice solution does leave the roads stained with red and brown, which can be unappealing to many. That being said, Laval, one of the earlier adopters of this solution, have started to use the juice from white beets to avoid the mess and others have decided to turn a blind eye in favor of the many benefits of this new de-icing solution.

What are your thoughts? Would the pros outweigh the cons and would you consider using beet juice as an alternative to road salt? Comment below!

Photo credit: deeproot

10 Responses

DOES BEET JUICE NEED SECONDARY CONTAINMENT WHEN USED FOR DE-ICING STREETS?

Hello Micheal, thank you for your question. When beet juice or beet molasses are used to de-ice the roads it could cause secondary consequences, as there is no perfect solution with zero downsides. As described in the article, it has been reported that runoff from this sugary beet solution can end up in streams where it attracts higher levels of bacteria, which in turn depletes the oxygen supply in the water and is problematic to the animals that rely on it, so secondary containment would be necessary. Hope this helps!

The beet juice molasses also is better at sticking to vehicles, and it is nearly impossible to get it off of the paint. When it is mixed with salt brine, does it not allow that brine/beet mixture to adhere to my vehicle better? When before all I had to do was go to the car wash and wash off the salt.

I wonder how many city, county and state highway departments will be fending off lawsuits from angry motorists with ruined paint, like on my new vehicle?

“Every action has an equal and opposite reaction”

One other downside to using beet juice is the odor – in my town (Lexington, MA, USA) it smells like dead fish after it is applied. I don’t know what the exact mixture my town uses, but I’ve heard that beet juice is being used. We do NOT have problems with the asphalt being stained – the fluid seems to be colorless.

It’s awesome to come across a blog every once in a while that isn’t the same out of date rehashed information.

great idea….let’s keep them coming, to eventually find the “perfect” solution….

Good Stuff!

We need a cheap alternative to salt. I’m tired of watching our infrastructure crumble because of something preventable.

I live in Cameroon, a country where there is not problem of snow for road users. However, I was very impressed by this finding: partial replacement of NaCl by by beet juice to keep Streets Healthy and Clear from ice!

Very cool! love it!

Awsome information! THANKS!!!