Giatec continues to uphold the value of bridging the gap between academic research and sustainable construction on the jobsite. Every year, we recognize civil engineering students, researchers and faculty across Canada and the U.S. with the Giatec Best Paper Award for Sustainability in Construction. Below is a summary of the 2019 winning paper submitted by Mo Li and her team, Unveiling Electromechanical Behavior of Cementitious Materials for Diagnosing Health of Concrete Structures. Find how you can join the list of winners and showcase your research to a global audience of industry experts while receiving a monetary award of 1,000 USD here.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Synopsis

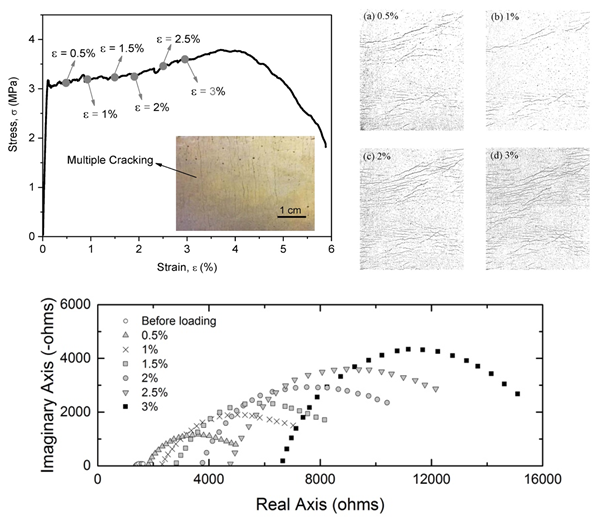

This work elucidated the effects of damage and self-healing on the frequency-dependent electrical response of strain-hardening cementitious materials. Electrical impedance spectroscopy was conducted before material cracking, during single crack opening, sequential formation of multiple microcracks, and subsequent self-healing of the microcracks. The results revealed that the material complex impedance was strongly influenced by crack opening and crack number; both changed during mechanical straining as well as the self-healing process. A new equivalent circuit model was formulated for predicting the frequency-dependent electrical response of the material during damage evolution and self-healing process. Analyzing the changes of model parameters revealed the mechanisms that contribute to the frequency-dependent electromechanical response of the material. This study generated new experimental data and analytical model coupling the electrical response with damage level in cementitious materials. The new understandings are critical for the next step of realizing damage sensing in strain-hardening cementitious materials through frequency-dependent AC measurements.

Summary

Health monitoring of concrete infrastructure is critical to prolonging structural service life through timely maintenance, ensuring safety and preventing failure. Current management practices of concrete structures rely on visual inspections, which can be subjective and are limited to accessible locations. For critical structures, structural health monitoring systems are installed and based on point sensors such as strain gauges, thermocouples and accelerometers. This indirect, point-based sensing approach is costly, requires complex analytical models to correlate the local measurements to structural mechanical state, and is highly difficult to provide spatial information on damage such as concrete cracking and deterioration, or reinforcement corrosion.

The AM3 Lab led by Dr. Mo Li at the University of California, Irvine aims to tackle these long-standing challenges through a direct and spatial sensing approach enabled by novel multifunctional strain-hardening cementitious materials. We encode the multifunctional cementitious materials with a distributed microcracking damage process coupled with self-sensing functionality. The sequential formation of steady-state microcracks enables a prolonged and controlled damage process with extraordinarily large tensile ductility, while allowing detection of strain and sequential damage long before localized fracture failure occurs. Through surface electrical probing and advanced tomography method, we are able to realize spatial damage sensing and visualization in reinforced concrete structural components. The advantage of the multifunctional cementitious material is thus two-fold. First, it provides high damage tolerance for improving infrastructure durability under service conditions and safety under extreme events; Second, it offers capacity for direct sensing of damage with spatially continuous resolution wherever the material is located, without the need of installing sensors.

How can we turn cement-based structural materials into spatial sensors? The key is to achieve a strongly coupled electromechanical behavior during material elastic, inelastic and cracking stages. However, this is not possible unless we have a fundamental understanding of the true electrical response of cementitious materials. Questions arise as to how the damage process affects the frequency-dependent electrical response, and how such effects can be captured in analytical models capable of explaining and predicting the electromechanical behavior of the material system experiencing cracking or deterioration. Although the past efforts have largely focused on resistance measurements of concrete under DC, resistivity cannot be a suitable measure for probing the true electrical behavior of concrete that possess a highly heterogeneous microstructure and often incorporate steel reinforcements.

To answer these key questions, the AM3-Lab at UCI performed frequency-dependent AC electrical impedance spectroscopy and equivalent circuit analysis on cementitious specimens. This work integrated experiments and modeling to unveil the effects of different mechanical damage stages on electrical impedance spectra. They included (1) the elastic straining stage; (2) single crack opening, representing localized fracture; (3) multiple microcracking, representing increasing damage levels; and (4) self-healing of cracks, representing a reversed damage process. Through impedance spectroscopy, we modeled the frequency-dependent electrical behavior of cementitious materials containing cracks by an idealized model circuit consisting of discrete electrical components, which describe the physical processes taking place in the material-crack system. Analyzing the changes of model parameters due to cracking and healing processes revealed the mechanisms that contribute to the overall electromechanical response and its AC frequency dependency of cementitious materials.

Our study was published in the journal paper titled “The effects of damage and self-healing on impedance spectroscopy of strain-hardening cementitious materials” in Cement and Concrete Research. We are honored to receive Giatec’s best paper award for this paper. The new knowledge will enable technologies that engage structural materials as spatial sensors to diagnose and protect structural health towards intelligent and more resilient infrastructure.

Read the full article in “Cement and Concrete Research” Volume 106, April 2018, Pages 77-90 Here

Authors, Mo Li, Shuai Fan, & Xiaopeng Li

Lead author, Mo Li is the director of AM3 Lab (Advanced and Multifunctional Materials and Manufacturing Research Laboratory for Infrastructure) and an associate professor at UC Irvine. She can be contacted at moli@uci.edu