Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Giatec continues to uphold the value of bridging the gap between academic research and sustainable construction on the jobsite. Every year, we recognize civil engineering students, researchers and faculty across Canada and the U.S. with the Giatec Best Paper Award for Sustainability in Construction. Below is a summary of the 2020 winning paper submitted by Keshav Bharadwaj, Deborah Glosser, Mehdi Khanzadeh Moradllo, O. Burkan Isgor, W. Jason Weiss under the title Toward the Prediction of Pore Volumes and Freeze-Thaw Performance of Concrete Using Thermodynamic Modelling. Find how you can join the list of winners and showcase your research to a global audience of industry experts while receiving a monetary award of 1,000 USD here.

Summary

Concrete is a porous material consisting of pores ranging from the nanometer scale up to the millimeter or centimeter scale. Many important properties of concrete are related to its porosity and the volumetric distribution of the pores. For example, historically, empirical models that relate the water-to-cement ratio (w/c) of concrete to achieve a target strength were used, as the w/c is often a surrogate for porosity in simple Ordinary Portland Cement (OPC) systems. In modern times, several supplementary cementitious materials (SCMs) are used along with OPC as they offer cost and performance benefits when compared to pure OPC systems. When SCMs are used in concrete, the drawback of empirical approaches that relate the water-to-binder ratio (w/b) of concrete to the strength is evident as the chemistry of reactions of OPC and OPC+SCM systems are different.

So, the question is, how do we predict the strength and other properties of concrete made with OPC and SCMs? One way is to understand the chemical reactions that take place in these cementitious systems. To this end, thermodynamic modeling is a very powerful tool that has been extensively validated and used to predict the reaction products and pore solution chemistry of OPC+SCM systems. Our research group at OSU works on developing models that relate the microstructure of concrete to its engineering performance.

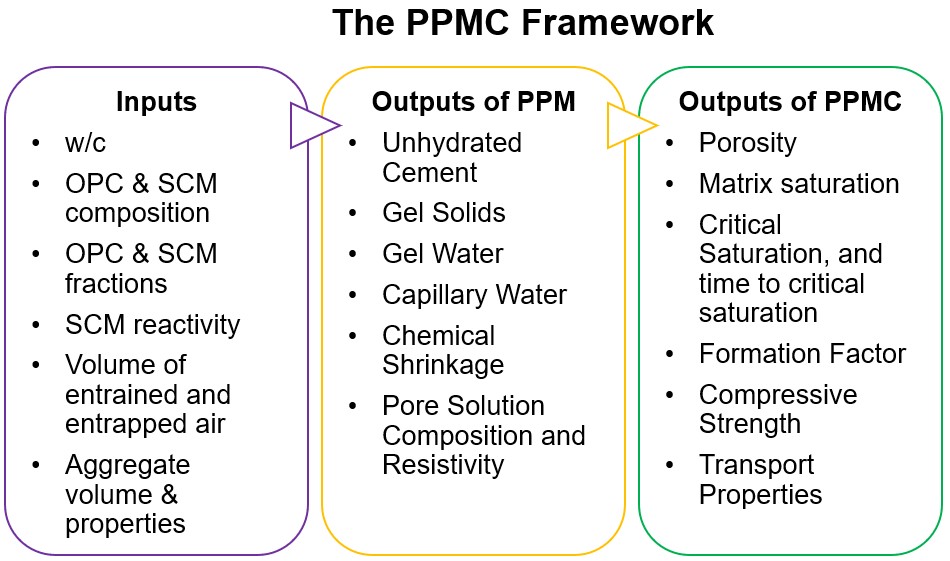

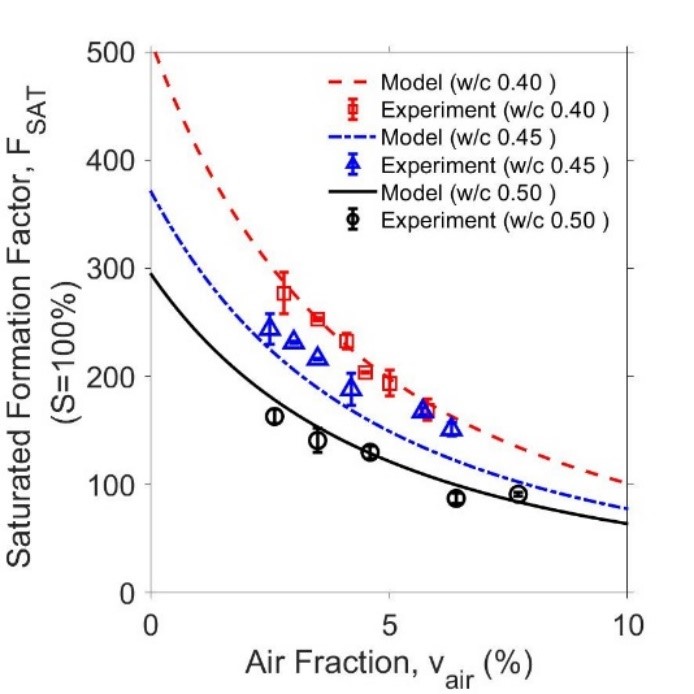

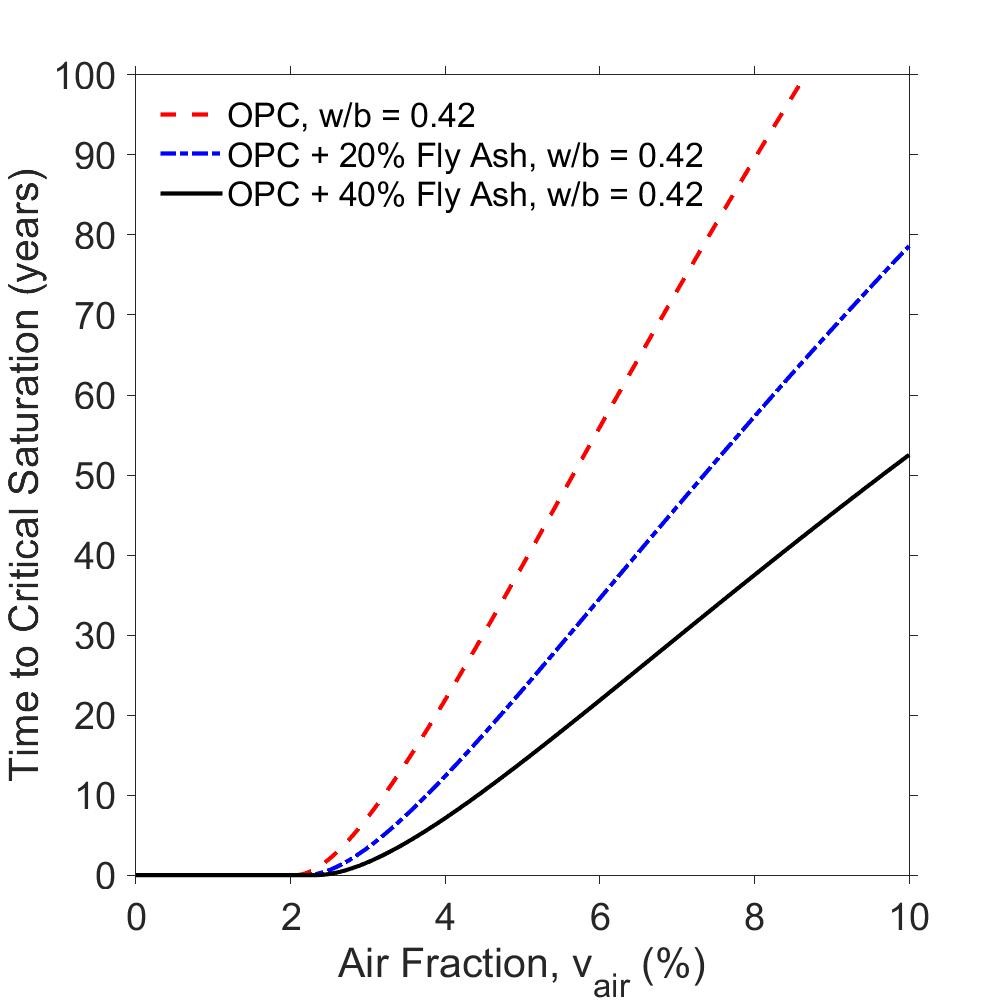

The research group has developed a model called the PPM (Pore Partitioning Model) that calculates the volumes of different sizes of pores in pastes made of OPC+SCMs based on the reaction products obtained from thermodynamic modeling. In this work, a new model is proposed that scales the PPM to concrete. The model, dubbed the “PPMC” (Pore Partitioning Model for Concrete; outlined in Figure 1), can be used to predict the porosity and pore volumes in concrete and predict several key performance properties, such as the porosity, strength, pore connectivity, and formation factor, time to critical saturation. A sample illustration of the capabilities of this model is shown in Figure 2, where the formation factor of saturated concrete of different w/c at varying air contents is predicted.

The formation factor of concrete is a very useful microstructural property to predict, as it is linked to the engineering performance of concrete. The formation factor can be used to predict chloride diffusion, water absorption, bulk resistivity etc. of concrete. In this work, the formation factor is used to predict the time to freeze-thaw damage in concrete systems made of OPC and OPC + Fly Ash to illustrate the power of this model. The predicted time to critical saturation (time to potential onset of freeze-thaw damage) is shown in figure 3 when a typical fly ash is used (composition and reactivity available in the full paper). One potential practical application of the PPMC framework is to determine the required volume of air entrainment to achieve a target life against freeze-thaw damage for a given concrete mixture. For example, a 20% replacement of OPC with the fly ash would require 1%-2% more entrained air to achieve the same freeze-thaw performance. The proposed approach can also be used to optimize the replacement of OPC with SCMs and air entrainment to meet the target durability requirements.

Read the full paper here.

Authors, Keshav Bharadwaj, Deborah Glosser, Mehdi Khanzadeh Moradllo, O. Burkan Isgor, W. Jason Weiss from Oregon State University.