By now, you might have noticed that we recently released a newly re-engineered version of our leading concrete sensor. This flagship product, SmartRock®, was introduced to the market back in 2015. In September of 2020, we were thrilled to release the third generation. The purpose of this blog is to guide you through the differences between the second and third generation of the SmartRock sensor. Usually, we refer to our product simply as SmartRock, but to help us compare, we will be referring to the second generation as SmartRock 2, and the third as SmartRock 3.

First, some background. Giatec developed SmartRock with the purpose of revolutionizing the concrete industry. The construction industry is slow to adopt new technology, yet outdated methods increase costs and timelines. Today, cylinder concrete break tests are the most widely used compressive strength standard for concrete construction. While this method has certainly allowed construction to prosper for many years, there are many problematic uncertainties that come along with it. These include errors such as low breaks, inaccuracies due to human error, and frequent delays, particularly from third-party labs.

SmartRock uses the maturity method according to “ASTM C1074: Standard Practice for Estimating Concrete Strength by the Maturity Method”. In short, the sensor is designed to help you build concrete structures faster, safer, and more economically. Continue reading to learn more about the benefits of SmartRock!

Read all about the maturity method here!

The Similarities

Before highlighting what is new with SmartRock 3, let’s take a look at some of our best features that have remained the same.

- As mentioned above, SmartRock was developed according to ASTM C1074. SmartRock 3 still fully complies with this standard.

- SmartRock is completely wireless and is designed to be fully embedded in the concrete. This way, you do not have to worry about damaging the sensor or tripping over wires.

- Both generations of SmartRock give you access to real-time data and 24/7 remote monitoring capabilities. This feature allows you to keep track of the status of your pour at all times directly on your smartphone.

- SmartRock can be connected to the SmartHub™ for remote monitoring. This allows you to check on the status of your concrete pour without going to the jobsite.

- You can use Giatec 360™, the world’s most advanced web-based dashboard for controlling and predicting the quality of concrete pours, with both generations of SmartRock. This platform allows you to monitor multiple projects at the same time, generate PDF/CSV reports for distribution, analyze temperature differential data and maturity threshold data, plus more!

How the Concrete Sensor Has Improved

Finally, we will look at what is new with SmartRock 3. The Giatec team has worked hard to improve our sensor in as many ways as possible, so we hope you like these new features as much as we do!

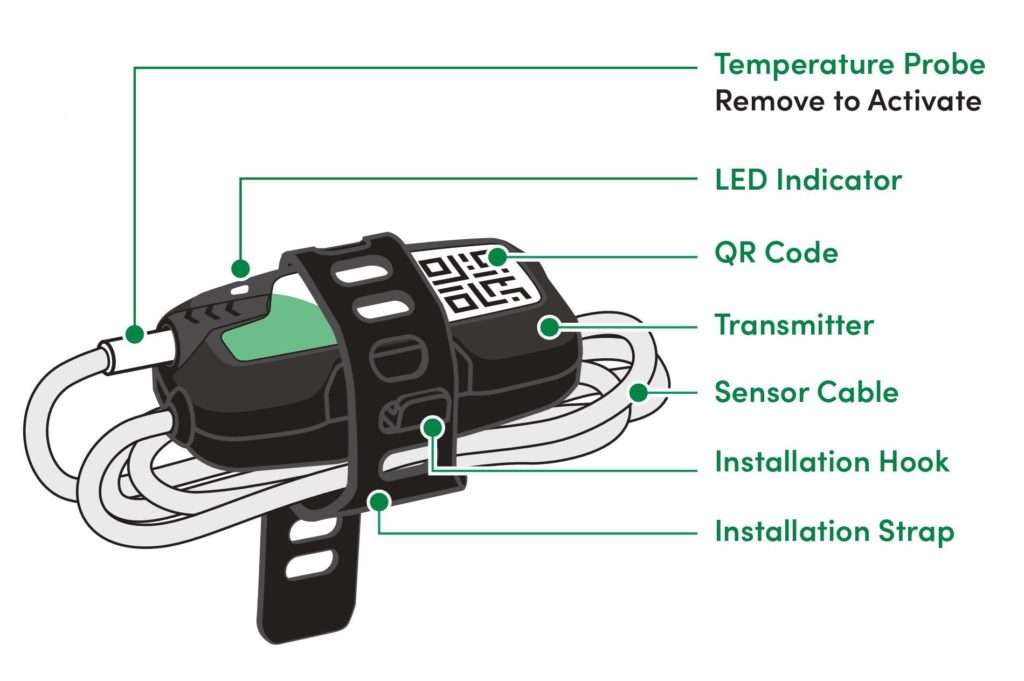

- Brand new design: SmartRock 3 has replaced the twist-tie wires on SmartRock 2 with an adjustable rubber strap that can withstand up to 40lbs of weight. Overall, this has made the sensor more durable and fit to handle any jobsite conditions.

- Longer range: Our sensor-to-phone signal range has increased from 26 ft (8 m) to up to 40 ft (12 m).

- Dual-temperature monitoring capabilities: An extra temperature probe has been added to each SmartRock 3 sensor for easy temperature differential analysis. With this new feature, you collect temperature data from both the body of the sensor and at the tip of the temperature cable, which is extremely helpful in monitoring mass pours.

Have you tried the latest version of our concrete sensor? Let us know what you thought of the new features in the comments!