Running temperature measurements of your pour after placement is one of the most important steps in the construction of a concrete structure. That is why ensuring optimal curing conditions for your element is critical, especially during extreme weather conditions. The hydration process (the chemical reaction between hydraulic cement and water) can be drastically impacted if freshly placed concrete is exposed to temperatures that are too high or too low, compromising the strength development of a mix design. Furthermore, if temperature differentials are too high, thermal cracking can occur. By closely checking temperature measurement variances with concrete temperature thermometers during element curing, you will ensure that the strength, quality, and durability of your structure are acceptable.

Find a concrete temperature solution for your next project!

When monitoring concrete temperature, one of the most commonly-used devices is thermocouples. There are wired sensors also known as concrete thermometers. The end of the thermocouple is placed at a specific location prior to the pour and wired outside of the formwork. Depending on the type of system, thermocouples are then attached to a data logger which is used to record the temperature measurements at certain time intervals.

Another variant of wired systems is a data logger/transmitter that sits outside the concrete in the form of a box connected to a number of temperature sensors. The transmitter uploads the data to the cloud server using wireless or cellular transmission technology. However, with these devices, the process of gathering, recording, and analyzing data is both time-consuming and labour-intensive.

For this reason, game-changing wireless systems, like SmartRock®, are being used on jobsites more often. With this method, temperature data is gathered, recorded, and analyzed entirely in an app. Not only does this save time, but it also reduces labour costs.

Learn more about the benefits of wired vs. wireless sensors for temperature monitoring here.

How Do Wireless Concrete Temperature Thermometers Work?

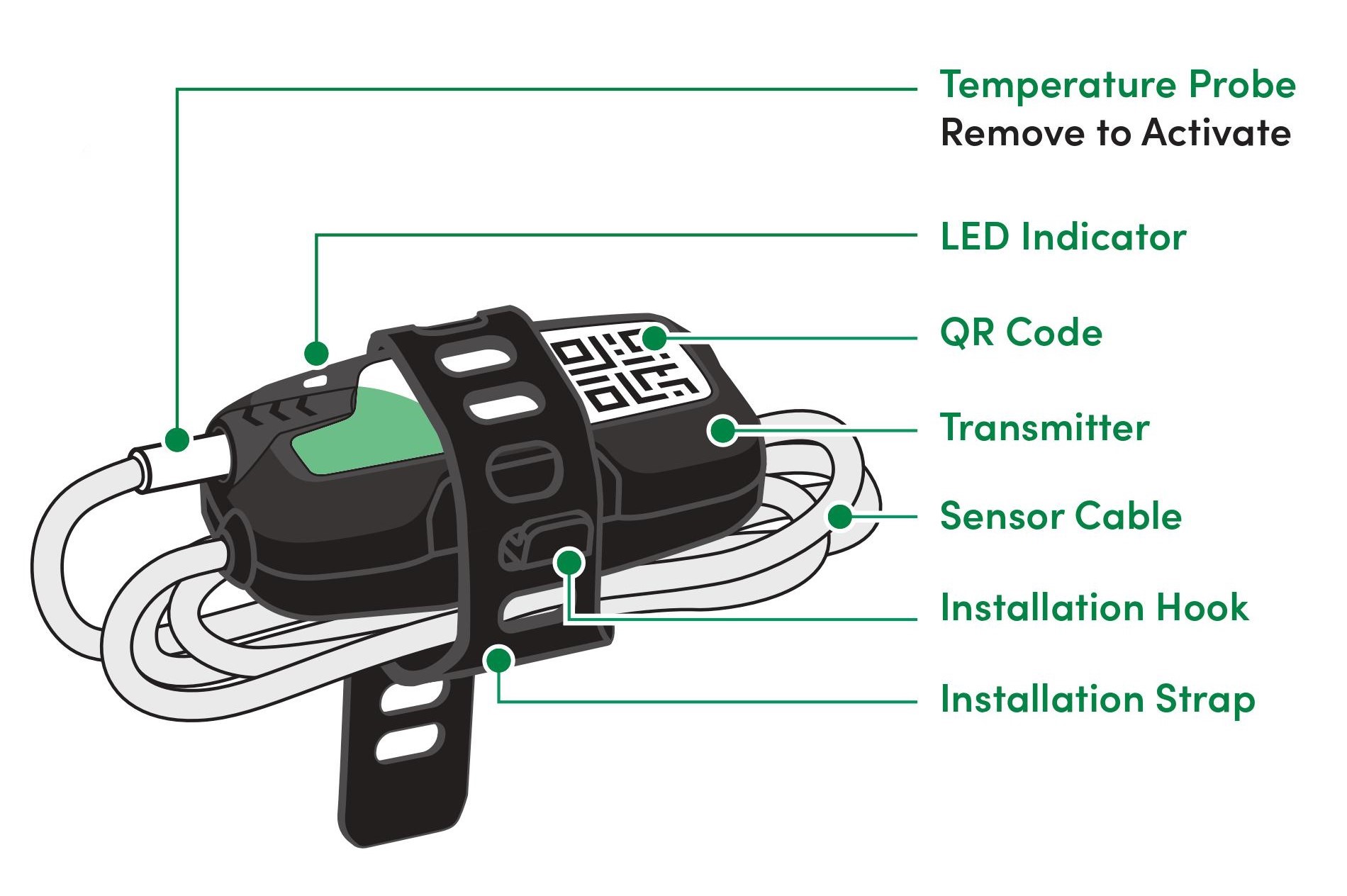

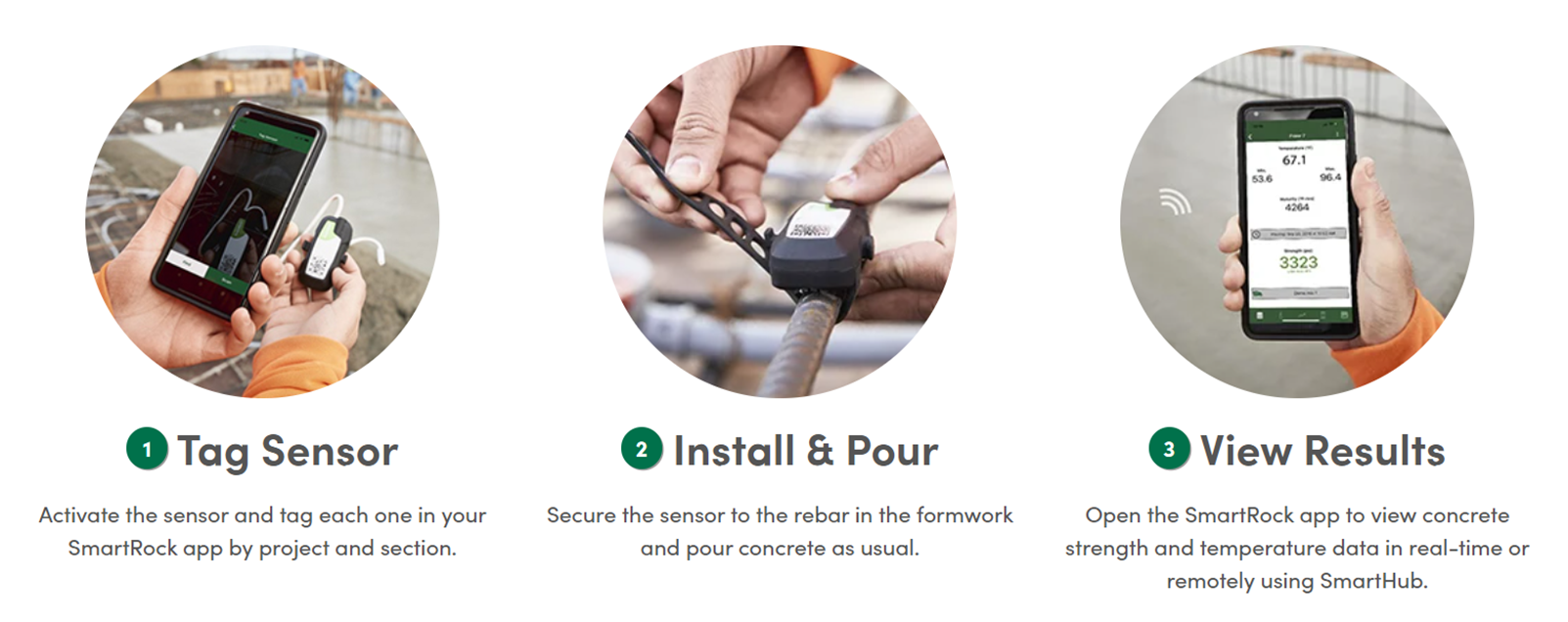

During installation, wireless concrete temperature thermometers, like SmartRock, are attached to the rebar before the concrete pour. Once the temperature probe is removed, the sensor activates and begins logging data. To access this data, the mobile device wirelessly connects to the sensors using the app (Android and iOS). Here, the data is updated every fifteen minutes for a two-month period. Connecting to the sensor and uploading the data is done automatically in your app once you are within 40 feet (12 meters) of any sensor. The sensors’ battery remains active for an additional two months in case additional data is wanted.

This method allows for highly accurate data to be collected and reported. Additionally, it enables project members to make timely and well-informed decisions onsite regarding the temperature of their element during the curing stages.

With a newly refined technology of concrete curing thermometer, the data can be accessed from any smart device through wireless communication. This capability allows for more freedom and security by removing the risk of damaging wires, mislabeling sensors, and general human error associated with data acquisition and interpretation. Throughout the data-gathering process, there is no need for last-minute repairs or adjustments once the sensor is placed in the concrete. The installation process is fast and simple, enabling nearly anyone onsite to implement temperature monitoring.

Look at this simple three-step process for installing wireless SmartRock temperature sensors:

Additional SmartRock Features

Giatec 360™: Web-Based Cloud Dashboard

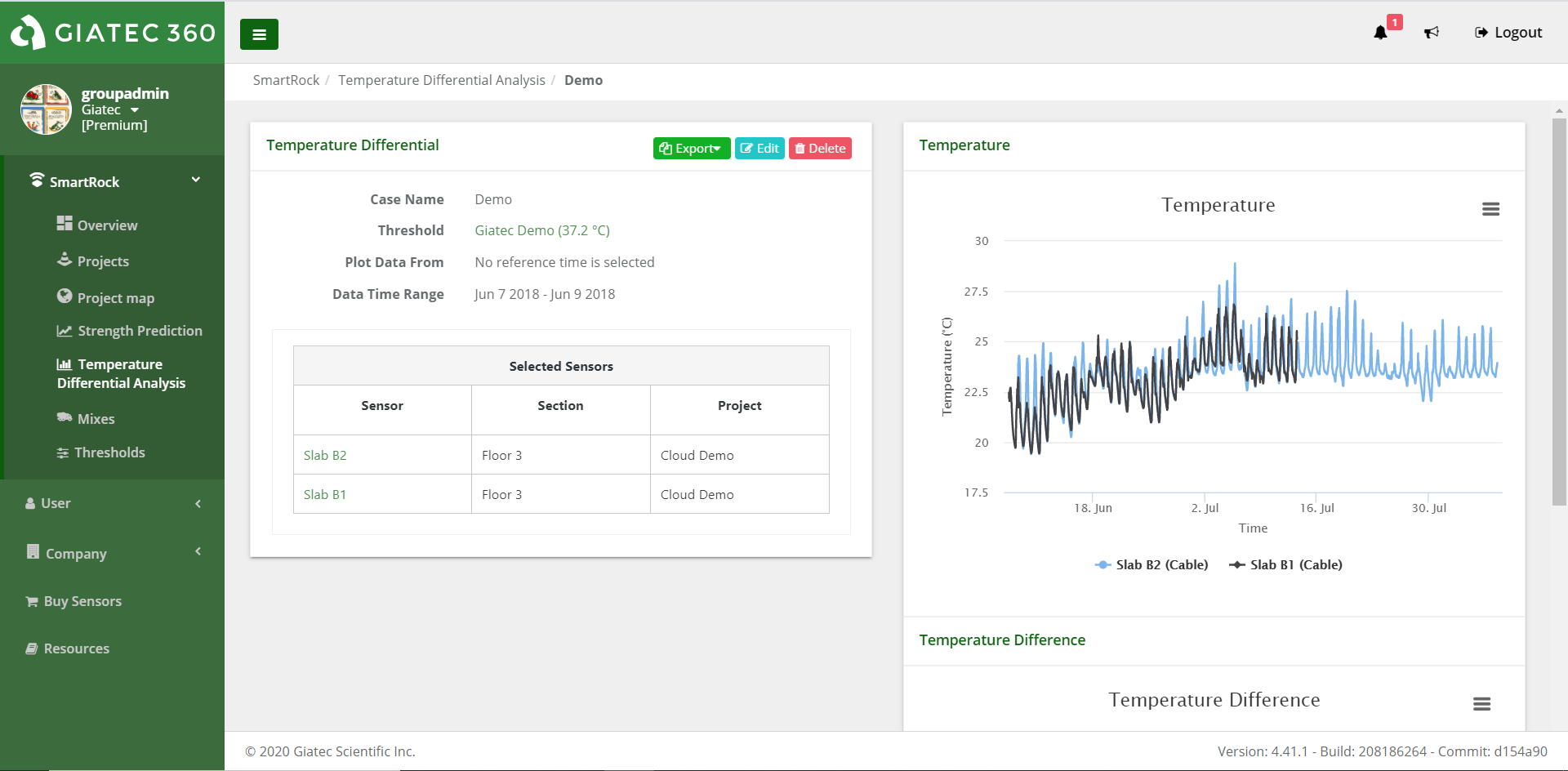

Giatec 360 is a web-based cloud dashboard where users can readily access all their project’s data in one place. The application allows you to monitor progress on multiple projects at the same time. This includes advanced analytical features such as temperature differential analysis and threshold settings. These features create a robust all-in-one product which enables project managers to generate reports and share data with ease while receiving vital updates on the curing conditions of their in-place concrete.

Learn more about Giatec 360 here

Collect and Access Data Even More Easily With the SmartHub™ Remote Monitoring System

Learn more about SmartHub here

Practical Applications for Wireless Concrete Temperature Thermometers

Temperature Monitoring for Mass Concrete Elements

Temperature differentials refer to the difference in concrete temperature thermometer, measuring sections of your concrete element, such as the inner core compared to the surface. In mass concrete elements, temperature differentials require continuous monitoring during curing. It must also adhere to a thermal control plan, as outlined in the project’s specifications. ACI 207.2R-07: “Report on Thermal and Volume Change Effects on Cracking of Mass Concrete” provides guidance on calculating the maximum allowable temperature differential based on the properties of the concrete and specifications for a structure to prevent thermal cracking. Typical temperature differential thresholds are in the range of 35°F (20°C).

SmartRock sensors come in two lengths to aid in monitoring both the core and the surface of mass elements. The real-time monitoring and data management provided by this product line assists in informing decision-making for the curing process. Furthermore, the addition of temperature differential thresholds enables project members to receive automatic push notifications in the Giatec 360 dashboard when concrete temperature measurements have met these thresholds. Also, if team members are not present onsite, the Hub will enable them to receive real-time updates on the status of in-place concrete.

Cold Weather Concreting

By providing added value in determining optimum heating conditions, SmartRock sensors allow you to create the ideal curing conditions for your projects. This can drastically reduce costs associated with the hoarding process. Added precautionary measures can be secured through our Giatec 360 dashboard, which allows the user to set temperature thresholds. When temperatures exceed these set parameters a push notification will be sent to project members. More information on concreting in cold weather conditions is specified in ACI 306R-16: “Guide to Cold Weather Concreting.”

Read these 7 tips for monitoring temperature during cold weather conditions here

Hot Weather Concreting

During hot weather, temperature and thermal conditions need to be constantly monitored to ensure proper concrete placement. Project specifications outline the maximum allowable delivery and curing temperatures of your element. The purpose of limiting the maximum temperature is to ensure that the concrete has enough moisture for the hydration process. To achieve optimal curing one can take many temperature reduction precautions. For example, adding ice and cooling aggregates to a batch. More information can be found in ACI 305.1-14 “Specification for Hot Weather Concreting”.

SmartRock provides added insight into the curing cycle of your element during hot weather concreting. With the ability to generate temperature data in real time you can see how your concrete is curing. This allows you to proactively determine if any cooling solutions are needed to control your concrete curing.

Using Wireless Temperature Sensors Onsite

“It was very easy and self-explanatory. No need even for training. It took me 30 minutes to install 10 sensors. Anyone on my jobsite could do it.”

– Frank Hoffman, Superintendent, Graham Construction

Read more about Graham Construction’s use of SmartRock sensors here

Following Industry Standards with SmartRock Temperature Sensors

- ASTM 1064 Standard Testing Method of Freshly Mixed Hydraulic Cement

- ASTM 1074 Standard Practice for Estimating Concrete Strength by the Maturity Method

- ACI 207.1 R-05 Guide to Mass Concrete

- ACI 207.2R-07 Report on Thermal and Volume Change Effects on Cracking Mass Concrete

- ACI 301-16 Specifications for Structural Concrete

- ACI 305.1-14 Specification for Hot Weather Concreting

- ACI 306R-16 Guide to Cold Weather Concreting

- ACI 306.1-90 Standard Specification for Cold Weather Concreting

- CSA A23.1/A23.2 Concrete Materials and Methods of Concrete Construction/Test Methods and Standard Practices for Concrete

Learn more about SmartRock wireless temperature sensors here

**Editor’s Note: This post was originally published in July 2019 and has been updated for accuracy and comprehensiveness.

2 Responses

Thermal Integrity profile testing in Piers? Do you have the equipment to do this type of testing?

Hi Marc, thank you for your comment. The SmartRock sensors come in two different length, 40cm (16 in) and 3m (10ft). It is possible to install temperature sensors at different depths in the structure to monitor the in-situ temperature every 15 minutes for a 2 months period. The SmartRock system is not explicitly made for thermal integrity profiling, TIP usually measures temperature very closely spaced along the shaft/pier length and the data is also used to detect irregularities in the concrete. If you are simply looking for temperature monitoring at specified depths, SmartRock would be a great solution for you. Feel free to contact support@giatecscientific.com with any other questions.