When it comes to testing compressive concrete strength, there are several methods to choose from. Field-cured cylinder testing is the most common method utilized for monitoring concrete strength on construction sites. For the most part, it has remained unchanged since its introduction in the early 19th century. However, its longevity doesn’t necessarily mean it’s the best technique to employ as it takes more time than others to complete and involves destroying concrete samples.

Let’s compare two other methods – the maturity method and the pull-out test – and explore their unique set of advantages and disadvantages.

Benefits of the Maturity Method

The maturity method is a technique that measures concrete strength in real-time and is based on the principle that concrete strength is directly related to its hydration temperature history. It is most often used for testing concrete at early ages, usually less than 14 days.

The temperature data is collected with sensors that are installed within the concrete formwork and subsequently uploaded to a smart device where the user can see the concrete’s psi/MPa in real-time.

SmartRock is an easy-to-use tool that allows in-field personnel to monitor concrete strength accurately and quickly while also minimizing costs over the longterm.

Pros:

- Accurate and reliable – Compressive strength data is given in real-time and updated every 15 minutes

- No time is wasted onsite waiting for results from a third-party lab

- Non-destructive

Cons:

- Requires a one-time calibration for each concrete mix to establish a maturity curve using cylinder break tests

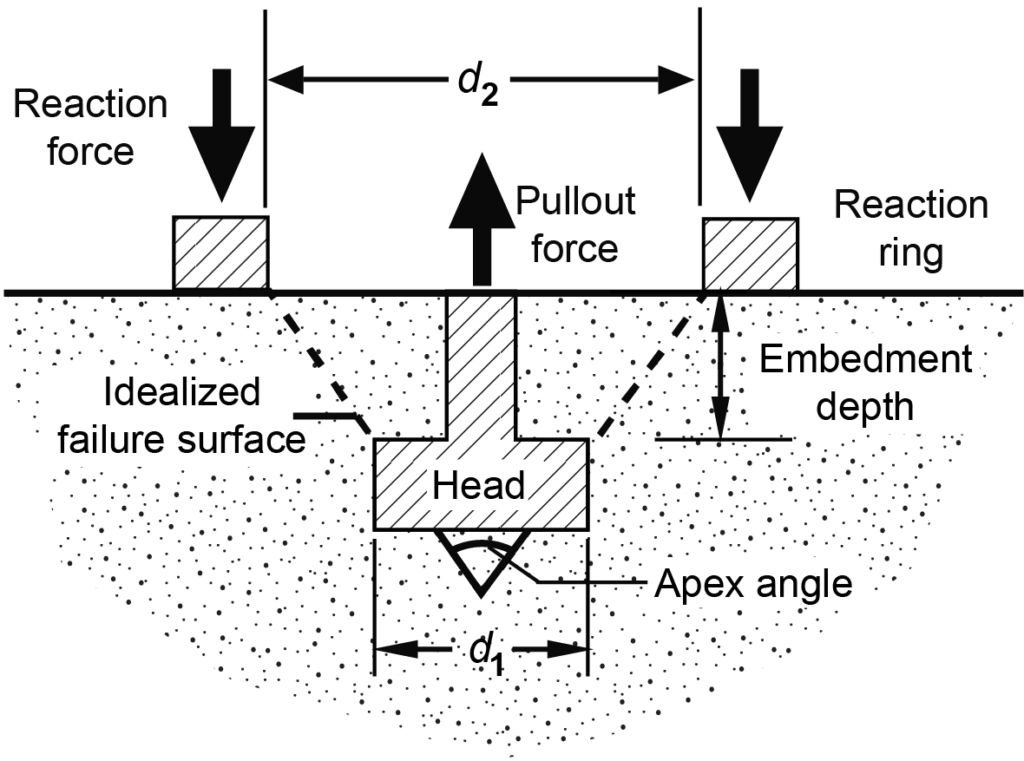

Pull-Out Test for Concrete Strength Monitoring

Pros:

- Easy to employ

- Can be performed on both new and old constructions

Cons:

- Semi-destructive in nature – This test involves breaking or damaging the concrete

- A large number of test samples are needed at different locations of the slab for accurate results, increasing costs and time involved

- Doesn’t measure interior strength of mass concrete as the pullout assembly only extends to about 2 to 3 inches into the concrete

Important Considerations for Concrete Maturity & Pull-Out Testing

What is your project timeline and when does it need to be completed?

Both tests are quick to implement. For the pullout test, a set of 10 pull-outs can be tested and the strength of a 100 m3 slab cleared for form removal in 20 minutes. However, the maturity method provides results in real-time.

How accurate do you need the data to be?

The pull-out test is accurate but requires tests in multiple locations on the construction site. The maturity method is more accurate as it measures the correlation between concrete temperature and strength in real-time.

Is non-destructiveness an important factor?

The maturity method doesn’t require damaging any concrete.

Are you focused on minimizing upfront costs or long-term costs?

The maturity method requires a higher upfront cost but provides more savings over the long term.

Which method is your team most comfortable using?

Discuss with your team which method they’re more comfortable using as this can affect safety, project timelines and costs.

Ultimately, the choice you make comes down to carefully weighing the pros and cons and figuring out which aspects are most important to the successful completion of your project.