One of the most talked about trends, not only in the construction industry, but in every field, is the discussion of the role of “big data”, especially when artificial intelligence comes into play. It’s undeniable that AI technology is better at handling large amounts of data than humans. What is done with this information is where the discussion becomes very interesting.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Currently, in the construction industry, artificial intelligence is largely being used to help make document management and project management systems more accessible. For example, to easily scan a PDF document and locate information quickly. AI technology is also being used to gather data collected by drones, recording devices, and internet of things (IoT) technologies, such as sensors.

What is Artificial Intelligence and Machine Learning?

AI is defined as “the theory and development of computer systems able to perform tasks that normally require human intelligence, such as visual perception, speech recognition, decision-making, and translation between languages.”

To achieve this, AI uses forms of machine learning to gain insights into this data. Machine learning provides these AI systems with the ability to automatically learn and improve from experiences without being explicitly programmed. This is done by analyzing algorithms and through pattern recognition. “The primary aim is to allow the computers to learn automatically without human intervention or assistance and adjust actions accordingly.”

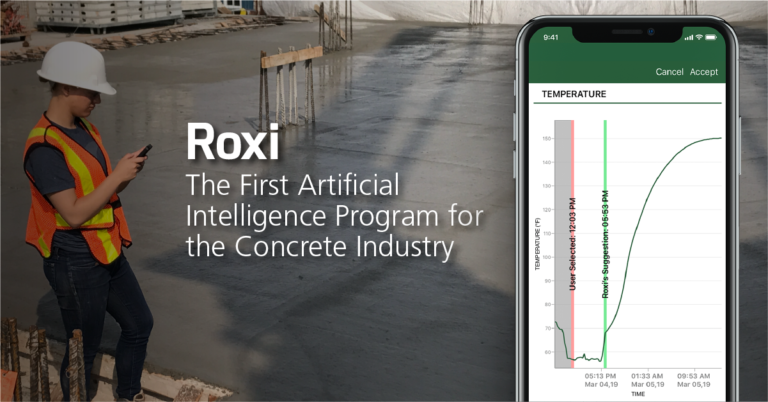

What is Roxi AI? Artificial Intelligence for Concrete Sensors

This year, the first AI program for concrete testing, Roxi, was introduced by Giatec. Roxi was developed in conjunction with Quebec’s AI institute, Mila (Montreal Institute of Learning Algorithms), whose founder of the machine learning laboratory, Yoshua Bengio, was recently awarded the Alan Turing Award.

“Being the leaders in concrete testing technology, we wanted to work with the leading authority on Artificial Intelligence to enhance our in-house machine learning capabilities. Roxi™ is another leap forward for Giatec, ensuring that concrete testing speeds up the construction process, rather than slow it down.” Says Aali R Alizadeh, Chief Product Officer and Co-Founder of Giatec.

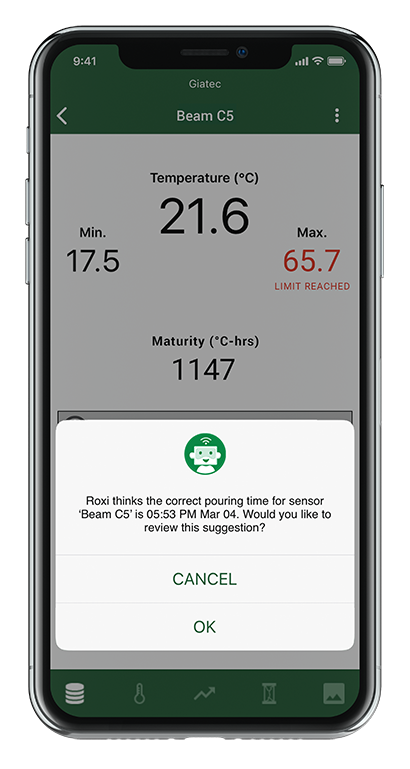

In analyzing the performance of concrete overtime using SmartRock®, Giatec hopes Roxi will become even more intuitive and be able to understand how concrete will behave in the future. This capability will allow the technology to predict in two days, for example, the strength value the concrete will reach. This means project managers will know in-situ strength ahead of their schedule.

What is SmartRock?

SmartRock is a wireless sensor that is placed within the concrete formwork, secured on the rebar, before pouring. Temperature data is collected by the sensor and uploaded to any smart device within an app using a wireless connection. This information is then used to calculate the compressive strength of the in-situ concrete element based on the maturity equation that is set up in the app. This strength data is considered to be very accurate and reliable as the sensors are subject to the same curing conditions as the in-situ concrete slab.

When you use SmartRock® on your jobsite, you get temperature and strength data uploaded on your mobile device every 15 minutes. This is done using a wireless signal, meaning you have to be onsite to collect this information. Equipped with real-time results, contractors can improve the heating process, decrease energy costs, and save time in their project schedule by knowing when to move on to subsequent construction operations, such as; formwork removal or post-tensioning. With the Giatec 360 desktop dashboard you can also check temperature gradients of your in-situ concrete so you can ensure that the core and surface of your slabs are consistently curing.

Learn more about the Giatec 360 cloud dashboard Here

Roxi™ will ultimately begin to detect anomalies at various stages of the concrete life-cycle including; production, delivery, placement, hardening, and while in service. The accurate real-time assessment and prediction of concrete performance during these stages is nearly impossible for humans

Future Benefits of Roxi AI for the Construction Industry

- Reduce the chance of human error

- Detect anomalies at various stages of the concrete lifecycle

- Access millions of data points

- Accurate real-time assessment and prediction of concrete performance

- Know concrete measurements ahead of schedule

- Learn when to move on to construction operations

- Generate new insights and information about concrete

“We’re now getting data on a worldwide basis, and nobody has been able to collect this much data from concrete quality and performance in one place,” says Aali R Alizadeh. “So, with millions of data points collected from SmartRock sensors in different jobsites, it was time to move to the next step and generate even more value from big data and give that value back to the end users.”

2 Responses

Interesting !

Can you further elaborate the AI functioning’s and data management for concrete and share any product brochure or journal.

Hi Umesh, you can read all about Roxi and download articles on the program here: https://www.giatecscientific.com/products/concrete-sensors/roxi/