It’s been a busy summer already for Giatec, and we’re not slowing down as we welcome four new members to the SmartRock® Plus producer family. These ready-mix producers have embraced technology by integrating wireless concrete sensors into their business models to optimize the performance of their mixes and offer contractors a more efficient way to monitor concrete temperature and strength at jobsites.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Cornejo & Sons – Wichita, Kansas

An industry leader in Kansas and the Midwest, Cornejo & Sons has been associated with quality construction projects and services for decades. Established in 1952, the company has been serving private and government clients in the community for more than 63 years. With over 575 employees and substantial plant and equipment resources, Cornejo & Sons products and services are suitable for a wide range of applications, from ready-mix concrete production and paving to wind farms and stone quarries.

Central Concrete Supply – San Jose, California

Central Concrete is a U.S. Concrete Company that has been operating for more than 60 years and has distinguished itself for its high-performance concrete. The company’s mixes are recognized for delivering high early strength, low shrinkage, and superior permeability—all while achieving a significantly lower carbon footprint than standard ready mixes. With 12 locations across the San Francisco Bay area, Central Concrete has a diverse portfolio that includes commercial and government projects, parking structures, mixed-use buildings, sports facilities, infrastructure, and housing.

Read more about Central Concrete Supply

Thomas Concrete Inc. – Atlanta, Georgia

A member of the Swedish, family-owned company Thomas Concrete Group that was established 1955, Thomas Concrete Inc. has 30 years of experience supplying high-quality ready-mix concrete to the American Southeast. As the largest independent supplier of ready-mixed concrete in its market, the company provides complete and effective solutions for all types of construction projects. With an extensive network of 65 plants, Thomas Concrete is able to provide shorter transportation times and ensure a greater regard for the environment.

Maschmeyer Concrete – Lake Park, Florida

With over 70 years of experience in the concrete industry, Maschmeyer Concrete is one of Florida’s leading American-owned and family-operated ready-mix supply companies. Since its founding in 1948, The company now has 17 locations and a fleet of over 200 delivery trucks serving central and southeast Florida. The company credits its success to consistently delivering quality products and services to its clients.

A Growing Demand for IoT Technologies in Concrete Construction

Our new partners have recognized that SmartRock® Plus is the perfect tool to differentiate their brand in an increasingly competitive industry.

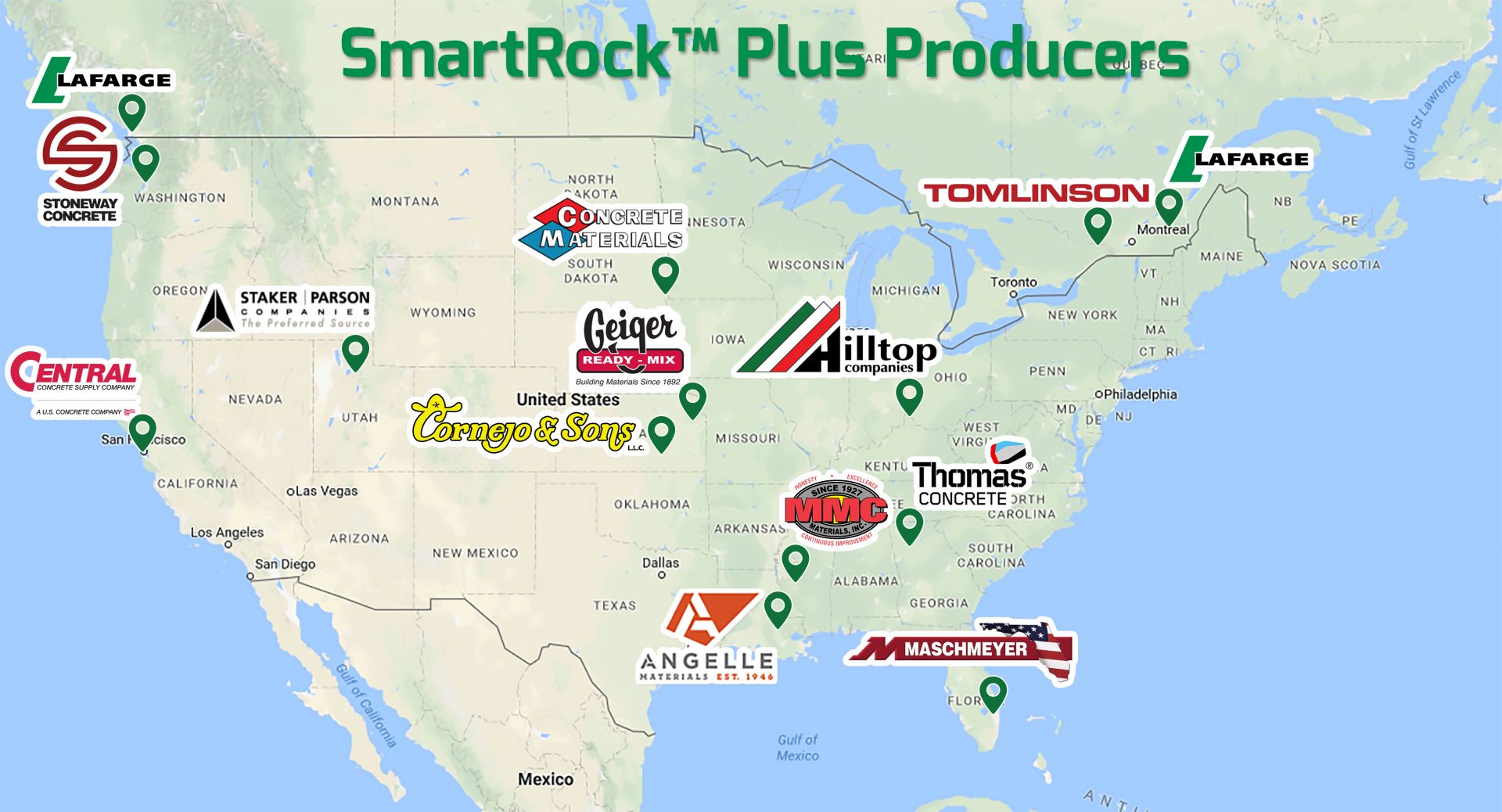

The above-mentioned companies are joining a number of North American ready-mix producers who are already benefiting from the SmartRock® Plus value-added solution, including: Staker Parson (Southwest USA); Lafarge Canada (British Columbia, Canada); MMC Materials (Mississippi, USA); Stoneway Concrete (Seattle, WA); Tomlinson (Ontario, Canada); Angelle Materials (Baton Rouge, LA); Hilltop (Cincinnati, Ohio); and Concrete Materials (Sioux Falls, SD).

Want to see how you can make your concrete “smart”? Download the SmartRock® Plus brochure.