The quality of your concrete directly depends on proper curing and accurate strength tests. While there are several different methods used to test concrete strength, not all of them are equally efficient. Below, we compare two methods of strength testing: concrete coring and concrete maturity.

For more methods, see our blog detailing seven different ways to test concrete strength!

Concrete Coring

Coring is the process of drilling and extracting cylinders of concrete for testing. These samples are then mechanically compressed to determine the strength of the in-place concrete. These cylindrical samples are intended to be representative of the concrete as a whole, and are generally used to verify or disprove low strength results obtained through other means of testing, such as field-cured cylinders.

The cored cylinders allow for an analysis of the concrete’s:

- Compressive strength,

- Splitting tensile strength, and

- Depth and durability.

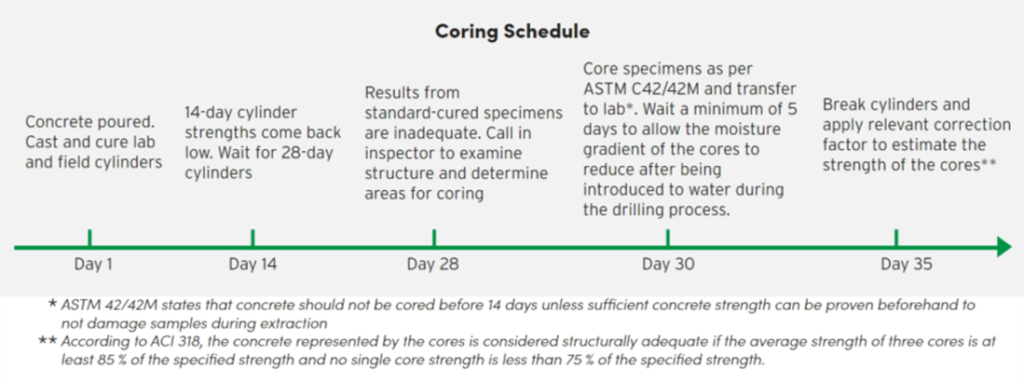

Coring is not an instantaneous process: cylinders must be drilled and transferred to the lab, before a five day wait to reduce the moisture gradient. See the schedule below for an idea of a typical concrete coring timeline.

The Maturity Method

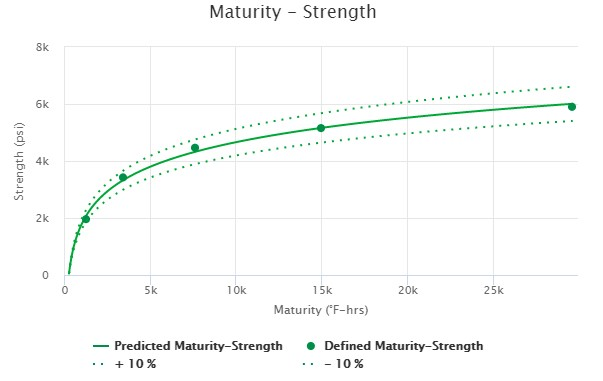

The maturity method is defined in ASTM C1074: Standard Practice for Estimating Concrete Strength by the Maturity Method, as “a technique for estimating concrete strength that is based on the assumption that samples of a given concrete mixture attain equal strengths if they attain equal values of the maturity index.”

To clarify, maturity is an index value that represents the development of curing concrete, as calculated through the concrete’s curing history. Concrete maturity relies on the measurement of time and temperature during the concrete curing process to accurately estimate concrete strength. As each concrete mix cures at different rates, a one-time mix calibration is also required to determine how strength develops in a particular mix as it progresses through the stages of curing.

Want an in-depth overview of the maturity method? Check out this blog!

Monitoring concrete temperature with the use of the right kind of maturity meter is necessary in order to implement the maturity method. This can be done in a variety of ways, but one of the most efficient and easy-to-use tools to monitor temperature is the wireless concrete sensor, SmartRock®. SmartRock is installed directly on the rebar before pouring concrete and wirelessly transmits data to a mobile application.

Maturity vs Coring

- Destructiveness: Coring requires extracting a sample from the concrete, a destructive process which leaves a hole in the concrete that must be repaired. Concrete maturity, on the other hand, is a non-destructive process. As the sensors are fully embedded, nothing is extracted from the structure and so there is no need for structural repairs due to strength testing.

- Accuracy: While coring uses a sample pulled directly from the in-situ concrete (ensuring that curing conditions are identical), what happens between the sample being extracted and being tested leaves room for mishandling which could lead to inaccurate results, costing you time and money. Concrete sensors, which are used for the maturity method, give accurate results in real-time, telling you the properties of the element directly, without the uncertainty.

- Frequency of Testing: Testing a cored sample produces a snapshot of concrete strength at one point in time. Maturity, on the other hand, allows continuous and real-time strength monitoring with no extra work needed to obtain the data (such as extracting a sample and sending it to a lab to be tested).

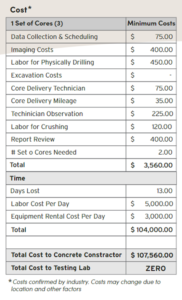

- Costs and Time: Coring can be quite expensive. Between paying for the labor needed to drill, deliver, and crush the cylinders, and costly delays while waiting on lab results, coring costs add up. Maturity sensors, however, are a one-time investment with no additional costs to use the sensors, and no need to pay for additional, specialized labor to analyze strength results. On the whole, the use of concrete sensors can save quite a big portion of your budget and your schedule.

Graham Construction was able to reduce labor costs by 85% using SmartRock! Read the case study here.

Simplifying Maturity With SmartRock

The SmartRock wireless maturity sensor enables easy implementation of the maturity method. SmartRock collects temperature data from two locations – one in the sensor body and the other in the tip of its cable. Then, this data is uploaded to a mobile application every 15 minutes, where strength and maturity calculations are done within the app. Whereas concrete coring requires back-and-forth with testing labs and extracting samples, all SmartRock requires to test strength using the maturity method is a mix calibration, a simple installation, and a mobile device.

By using the maturity method and wireless sensors, you can reduce the need for coring, and take back control of your project with data that is easier to obtain, more accurate, and non-destructive.