Before we delve into the process of its removal, it is essential to understand what “formwork” means in the concrete sphere. As described by Hunker, formwork that is set prior to pour concrete “serves as a frame for the shape of the concrete, holding the poured material in place as it cures.” So why the question of removing formwork? During the conclusion of its curing stage, concrete reaches a desirable level of hardness which ensures its ability to support its own weight, thereby eventually rendering the formwork unnecessary. This level of hardness, measured in MPa or PSI depending on the country is set out in the project specifications by an engineer. In this blog, we will go over all the steps to guide you through the meticulousness of formwork removal, tips for damage prevention, and the benefits of cycling formwork.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Step 1: Checking the Concrete

- To ensure a firm surface, make sure to confirm that the concrete is cured, in that it is hard and dry to adequate measure.

- Do you want to be confident that your concrete is cured as per the above-mentioned suggestions? We would encourage you to check out Giatec’s SmartRock®, the world’s leading wireless sensor for temperature and strength monitoring that provides results more accurate than field-cured cylinder breaks.

- Weather is a key element to factor in when checking if your concrete is ready because the required concrete removal time in winter is considerably higher than during summer.

Click here to read why you should be monitoring your concrete’s curing temperatures!

Step 2: Tackling the top

- Form removal must always be approached from the top of a sloping slab.

- A hammer comes in handy when dislodging nails that hold the forms together.

- Slabs and beams usually undergo a live load whilst in the construction process, so ensure that the achieved strength is sufficient to manage such loads.

Step 3: Ground and Sides

- The stakes that support the forms from the ground must be removed using a stake puller since this helps avoid any damage to the forms or the stakes.

- Forms can be pulled away from the sides of the concrete slab with the use of minimum strength, but if a form becomes challenging to remove then a pry bar helps to loosen the form in the concrete when pried upwards from the ground.

- Alternate the sides of the slab when removing forms as this helps to preserve the balance of the structure, and make sure to reuse the forms if they can be cleaned and dried, or dispose of them if necessary, instead.

In keeping these points in mind, it is pertinent to plan for contingencies or choose more optimal processes regarding numerous factors––whether they may concern the type of cement, the grade of concrete, or even accelerating the curing process.

Below, we have laid out some of the ways in which you may optimize your formwork stripping process or prevent undesirable outcomes during this procedure:

Tips for Formwork Removal Optimization

Here are some resources, methods, standards, and practices that will help you determine if the concrete has reached the desired level for the formworks to be stripped:

- ACI (1995) In-place methods to estimate concrete strength. ACI 228. 1R-95.

- ASTM (1987) Standard Practice for Estimating Concrete Strength by the Maturity method. ASTM C1074-87

- BS 8110 – Code of Practice for the Structural Use of Concrete

- IS-456 – Plain and Reinforced Concrete – Code of Practice

Here is a formula that will help you calculate safe formwork striking times:

(Dead load + construction load) / (total design load)

= Grade of concrete

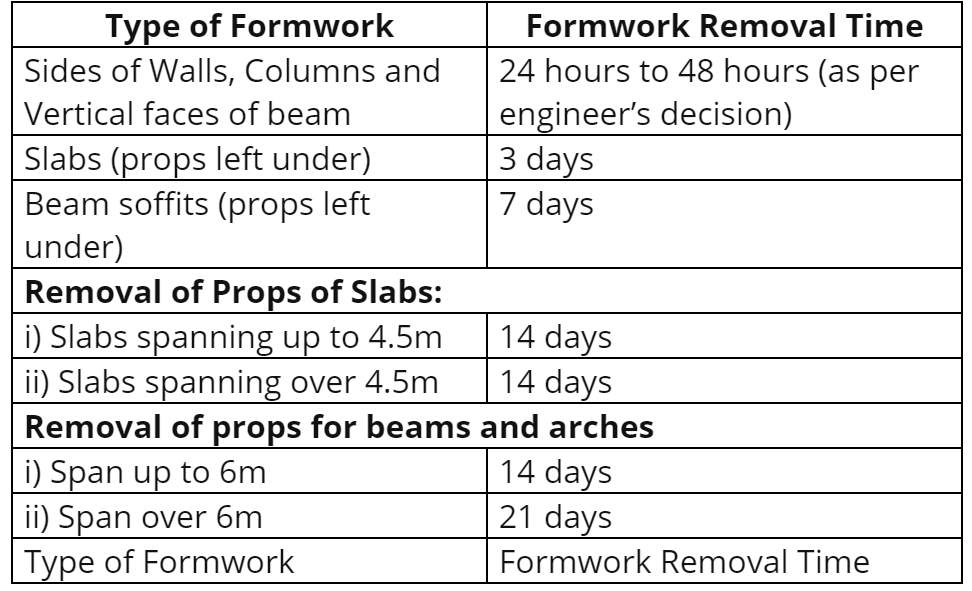

The following is a table obtained from LCETED Institute for Civil Engineers which provides formwork stripping times for reference:

Formwork Removal Time (Ordinary Portland Cement)

Tips for Damage Prevention During Formwork Removal

- Avoid using the force of tools such as crowbars whilst removing the formwork as this may damage the concrete, but a preferable alternative would be wooden wedges.

- There are several risks to removing the formwork too early and these may include: columns and beams sides could bulge or misalign if the concrete is not hard enough, or the structure could collapse without adequate strength.

- It is highly recommended to seek the approval, supervision, and/or expertise of the on-site engineer for matters concerning the organization (pattern/sequence) of formwork removal as well as to confirm the quality of hardened concrete.

The Benefits of Cycling Formwork

Cycling formwork is a great way to make sure your jobsite is as efficient as it is sustainable. Now, why would formwork cycling be optimal for your project? In almost any situation when the reuse of formwork is possible, it can save money and time during a slab’s curing process. These cost and time-saving benefits prove their worth to any project as it eliminates other formwork issues concerning transportation and installation. The simplicity of reusing formwork makes construction better for the environment while improving a project’s scheduling and costs which makes cycling a practice of the future.

Giatec’s SmartHubTM is a remote monitoring system that allows you to access your SmartRock data at any time, from anywhere, aiding you in procedures like concrete formwork removal. Click here to learn more about our product.

Sources

LCETED Institute for Civil Engineers

*Editors Note: This post was originally published in June 2021 and has been updated for accuracy and comprehensiveness in May 2023.