Three-dimensional concrete printing (3DCP) is an innovative construction method that employs additive manufacturing techniques to create structures by layering concrete material based on digital designs. This approach offers numerous advantages over traditional construction methods, including enhanced design flexibility, reduced waste, accelerated project timelines, and potential cost savings.

Build Data Centers Faster with SmartRock® Long Range

As the construction industry grapples with challenges such as labor shortages, high material costs, and the imperative for sustainable practices, 3DCP emerges as a promising solution to address these issues. In this blog, let’s take a look at the history, its impact on the concrete industry, the challenges and benefits, as well as the future of 3D concrete printing.

The History of 3D Concrete Printing

The story of 3D concrete printing didn’t begin overnight. It’s built on decades of innovation, experimentation, and engineering breakthroughs. From early attempts at layered construction to the introduction of automated building technologies, these milestones set the stage for what’s now reshaping how we design and build with concrete. Let’s take a look at these early developments:

- Joseph E. Blanther’s Patent (1892): In the late 19th century, Joseph E. Blanther patented a method for creating topographical maps through layered techniques, laying the groundwork for additive manufacturing concepts.

- William Urschel’s Wall-Building Machine (1930s): Inventor William Urschel developed a machine capable of constructing walls by extruding concrete in layers, a precursor to modern 3D concrete printing technologies.

- Stereolithography (SLA) by Charles Hull (1984): Charles Hull introduced stereolithography, a process that fabricates 3D objects using photopolymerization. This innovation significantly influenced subsequent developments in additive manufacturing, including 3D concrete printing.

- Contour Crafting by Behrokh Khoshnevis (Late 1990s): Professor Behrokh Khoshnevis pioneered Contour Crafting, a technique aimed at constructing large-scale structures rapidly through automated layering of concrete, marking a significant advancement in automated construction methods.

- D-Shape by Enrico Dini (2007): Enrico Dini developed the D-Shape printer, utilizing a binder jetting process with sand to create stone-like structures, expanding the possibilities of complex architectural forms in construction.

- Advancements at Loughborough University (Late 2010s): Researchers at Loughborough University made significant strides in refining 3D concrete printing technologies, focusing on improving print precision, material properties, and structural integrity, thereby enhancing the practical applications of 3DCP in the construction industry.

What is 3D Concrete Printing?

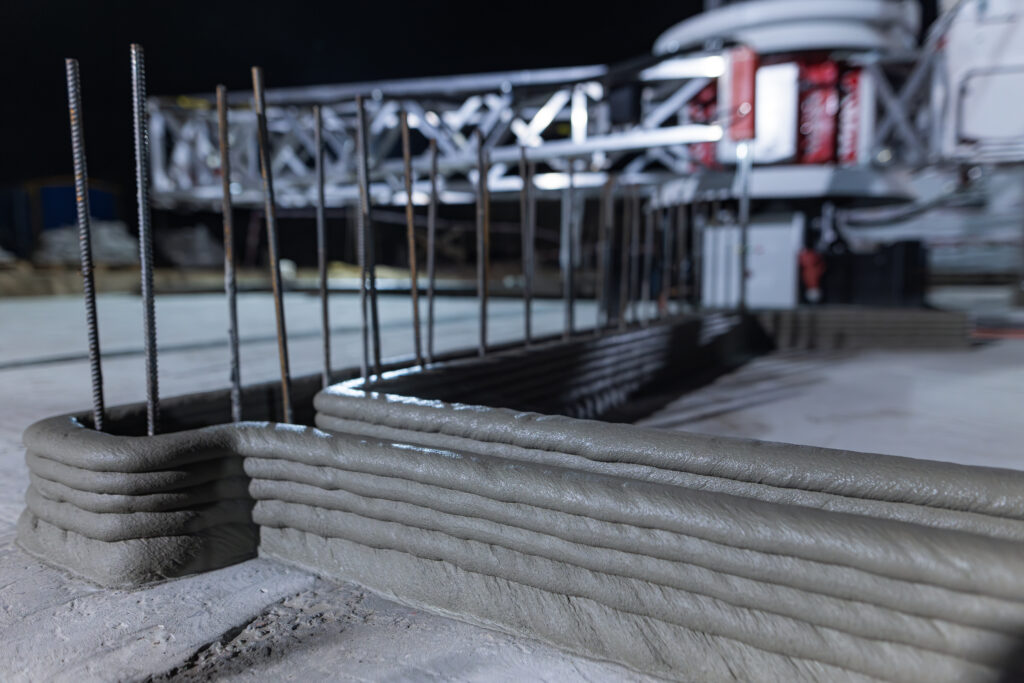

3D concrete printing is a subset of additive manufacturing that involves the gradual layering of concrete material to construct buildings or structural components directly from digital models. This method minimizes material waste, reduces labor requirements, and allows for the creation of complex geometries that are challenging to achieve with traditional construction techniques.

Check out some of the latest techniques used in 3D concrete printing:

- Material Extrusion: The most prevalent method in 3DCP, where a nozzle extrudes a continuous flow of concrete material, depositing it layer by layer to build the desired structure.

- Particle Bed Binding: This technique involves spreading a layer of powdered material and selectively binding it using a liquid binder or other means to form solid structures.

- Material Jetting: Involves the selective deposition of droplets of material, which then solidify to form layers, allowing for high precision in creating complex structures.

Material Must-Haves for Successful Printing

For 3D concrete printing to be effective on a structural scale, the materials used must meet specific performance criteria. These properties ensure that the concrete can be reliably printed without compromising quality or safety. These properties include:

- Extrudability: The concrete mix must be capable of being pumped and extruded through a nozzle without segregation or blockage, ensuring a consistent flow during the printing process.

- Buildability: Once deposited, each layer of concrete must possess sufficient strength to support subsequent layers without deformation or collapse, maintaining the structural integrity of the build.

- Workability: The fresh concrete should retain its shape after extrusion, allowing for precise placement and adherence to the design specifications.

- Interlayer Adhesion: Strong bonding between layers is crucial to ensure the overall structural performance of the printed element, preventing weaknesses at the interfaces.

- Open Time: This refers to the time window during which the concrete remains workable and can effectively bond with new layers, influencing the scheduling and speed of the printing process.

Understanding and optimizing these material properties is key to ensuring successful 3D printing outcomes, from the durability of printed structures to the efficiency of the construction process itself.

What Sets 3DCP Apart From Traditional Construction Methods?

With the increasing adoption of innovative methods, 3D concrete printing is proving to be a ground-breaking force in the concrete industry.

Its advantages extend far beyond automation, reshaping how we think about design, speed, cost, and sustainability in modern building practices:

- Design Flexibility: 3DCP enables the creation of intricate and customized designs that are difficult or impossible to achieve with conventional formwork, allowing for greater architectural creativity.

- Cost Reduction: By minimizing material waste and reducing labor costs through automation, 3DCP can lead to significant cost savings in construction projects.

- Accelerated Construction: The automation and precision of 3DCP can substantially reduce construction times, enabling faster project completion and earlier occupancy.

- Sustainability: 3DCP promotes sustainable construction practices by reducing material waste, enabling the use of recycled materials, and potentially lowering the carbon footprint of building projects.

Taken together, these benefits highlight why 3D concrete printing is gaining traction as a smarter, more efficient alternative to traditional construction methods.

The Roadblocks to Widespread 3D Printing Adoption

While the potential of 3D concrete printing is undeniable, the technology still faces a number of practical and regulatory hurdles. Addressing these challenges is essential to unlocking its full value at scale. Some challenges include:

- Material Consistency: Developing concrete mixes that are suitable for extrusion and possess the necessary structural properties remains a critical area of research and development.

- Regulatory Framework: The lack of standardized building codes and regulations for 3D-printed structures poses challenges for widespread adoption and approval of 3DCP projects.

- High Initial Investment: The acquisition of specialized 3D printing equipment and technology requires significant upfront capital, which may be a barrier for some construction firms.

- Technical Expertise: Operating 3DCP machinery and managing the associated digital workflows necessitate specialized skills and training, highlighting the need for workforce development in this emerging field.

As research progresses and industry standards evolve, many of these barriers are expected to diminish. This paves the way for broader implementation and long-term impact!

Build Data Centers Faster with SmartRock® Long Range

Building a Greener Future With 3D Concrete Printing

Beyond the immediate benefits of reduced material waste and labor efficiency, 3DCP aligns with broader sustainability objectives, including several of the United Nations’ Sustainable Development Goals (SDGs). By enabling the construction of affordable housing, reducing resource consumption, and promoting innovation in industry and infrastructure, 3DCP contributes to sustainable urban development and responsible consumption and production patterns.

Notable Examples of 3D Concrete Printers

- WinSun’s 3D-Printed Apartment Block (Jiangsu Province, China): In 2015, Chinese company WinSun constructed a five-story apartment building using 3D printing technology. This project showcased the potential for high-rise structures built through additive manufacturing, highlighting significant advancements in construction technology.

- Wolf Ranch 3D-Printed Community (Texas, USA): A collaboration between ICON and Lennar has led to the construction of a 100-home neighborhood in Texas, demonstrating large-scale residential application of 3D printing.

- Dubai’s “Office of the Future” (UAE): The world’s first fully functional 3D-printed office building was completed in 2016 using robotic arms and specialized concrete, setting a precedent for commercial 3D-printed structures.

- Europe’s First 3D-Printed House (Eindhoven, Netherlands): In April 2021, a Dutch couple became the first inhabitants of a fully 3D-printed house in Eindhoven, Netherlands. The 94-square-meter residence features energy-efficient design with extra-thick insulation and a connection to the heat grid. This milestone demonstrates the potential of 3D printing technology in providing habitable and sustainable housing solutions.

- TECLA Eco-Friendly 3D-Printed Homes (Italy): Developed by Mario Cucinella Architects in collaboration with WASP, TECLA is an innovative housing prototype that integrates research into vernacular construction practices, climate studies, and bioclimatic principles. It utilizes locally sourced clay, making the structure biodegradable and recyclable, effectively creating a zero-waste building. The project aims to provide sustainable housing solutions adaptable to various environments.

Want to learn more about sustainable construction practices? Download our guide here.

Standards and Regulations for 3D Concrete Printing

To ensure the safety, durability, and quality of 3D-printed structures, various standards and guidelines have been proposed:

- ASTM WK89706: Covers fresh and early-age properties of printable concrete to ensure material consistency and reliability.

- ASTM WK89707: Focuses on the construction process and documentation for additively manufactured concrete components.

- ASTM WK90347: Details curing and extraction methods for sample testing in 3D-printed structures.

- ASTM WK90348: Specifies the determination of hardened mechanical properties of 3D-printed concrete elements.

While these standards are still evolving, regulatory bodies and research institutions worldwide are working to establish comprehensive codes for 3D-printed buildings.

Future Trends of 3D Concrete Printing

As 3D concrete printing continues to evolve, the technology is expected to address critical global challenges, including:

- Affordable Housing Solutions

With increasing housing shortages worldwide, 3DCP can provide faster and more cost-effective solutions for building affordable homes, particularly in disaster-stricken or developing regions. - Sustainable Construction

The integration of recycled materials and eco-friendly binders in 3D printing will further reduce construction’s environmental impact, aligning with global sustainability goals. - Automation and AI Integration

The future of 3DCP may see increased use of artificial intelligence and robotics, enhancing precision, efficiency, and customization in construction. - Larger and More Complex Structures

Advancements in material science and printing technologies will allow for the construction of high-rise buildings, bridges, and other large-scale infrastructure projects. - On-Site vs. Off-Site Printing

While current 3DCP projects often involve off-site prefabrication, future developments may enable fully autonomous, on-site printing for faster and more adaptable construction.

The next chapter of 3D concrete printing will be driven by cross-disciplinary innovation and a shift in how we approach the built environment. With continued momentum, this technology has the potential to redefine construction as a platform for smarter, more resilient, and adaptive infrastructure.

Conclusion

3D concrete printing is revolutionizing the construction industry by offering a sustainable, cost-effective, and highly flexible alternative to traditional building methods. From residential homes to commercial buildings and infrastructure, the technology is proving its value in diverse applications worldwide. As research progresses and regulations mature, 3DCP is poised to become a mainstream construction method, shaping the future of architecture and urban development.

Interested in exploring other innovative construction technologies? Check out SmartRock wireless concrete sensors®!