The concept of artificial intelligence in concrete is frequently discussed, yet its practical application and effectiveness remain elusive. Despite the buzz, there seems to be a lack of understanding of what industry challenges can be solved with artificial intelligence and how. Hence, there is a need to shed light on its practical implications, bridging the gap between theoretical concepts and tangible solutions.

As a pioneer in artificial intelligence in concrete, Giatec® interviewed quality control professionals from over 20 companies throughout North America. The purpose was to identify primary challenges impacting their businesses and areas where artificial intelligence could effectively apply. The interviews revealed four key issues consistently present across companies of all sizes and market demands:

- Supply Chain Unpredictability: Fluctuating material availability, transportation issues, and unforeseen disruptions continue to drive supply chain unpredictability. These uncertainties often prompt overdesign to mitigate potential risks. While this serves as a protective measure, it can also lead to a significant increase in costs.

- Unreliable Testing Procedures: Testing quality variations and technical expertise gaps can jeopardize concrete meeting specifications, regardless of its actual performance. Consequently, producers often opt for overdesign as a precautionary measure to ensure they meet performance requirements.

- Labor Shortages: Our industry relies heavily on skilled labor for tasks such as mixing, pouring, and finishing concrete. However, a shortage of skilled workers, coupled with an aging workforce, poses significant challenges in recruiting and retaining qualified personnel. To address these challenges, producers often overdesign concrete mixes, sometimes unintentionally, to compensate for gaps created by labor shortages.

- Disorganized Data: Producers are keen to adopt new technology but are challenged by the amount of data living in different silos. Apart from general inefficiency, producers struggle to gauge the extent of their overdesigning and its financial impact without centralized data.

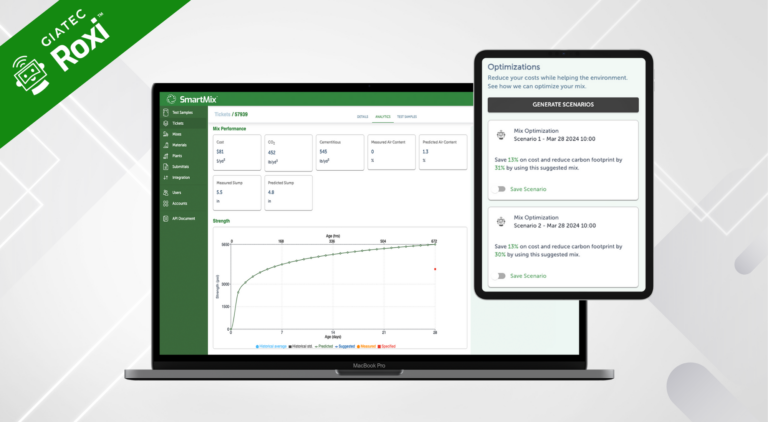

Understanding these challenges better, it became evident that they all converge into a central issue: overdesign. Rooted in a complex interplay of industry dynamics, overdesign leads to excessive material usage, increased costs, and environmental waste. Moreover, it contributes to inefficiencies in concrete production, hindering progress toward sustainability goals and impeding overall industry advancement. Tackling overdesign is essential not only for cost reduction and resource conservation but also for driving innovation and competitiveness in the concrete industry. This is where Roxi™ and Giatec’s SmartMix™ come in; offering a proactive artificial intelligence solution to overcome these challenges and enable producers to optimize concrete mixtures while taking control of their operations.

Introducing the Concrete Artificial Intelligence Solution: Roxi

Who Is Roxi?

Launched in 2019, Giatec’s Roxi marked a significant milestone as the first artificial intelligence program created for concrete testing. It was developed in collaboration with the Montreal Institute of Learning Algorithms (Mila), Canada’s World-Renowned Artificial Intelligence Institute. Roxi’s journey began as a humble AI algorithm integrated into Giatec’s flagship product, SmartRock®. Initially designed to detect pouring times and mitigate human errors, Roxi showed promise in enhancing data accuracy and streamlining processes. Through analyzing thousands of mixes, she evolved to grasp the extent of overdesign and identify areas for improvement while still mitigating risk.

How Roxi Shaped the Journey to SmartMix

After examining over 10 million cubic meters of concrete mixtures, Giatec found overdesign to be alarmingly prevalent, averaging 25%. This data helped quantify the well-known issue, that by erring on the side of caution, producers are overdesigning in excess to compensate for poor visibility and testing. Recognizing these implications, Giatec saw the need for an AI-powered solution to drive efficiency, sustainability, and innovation in concrete material management. This realization marked the beginning of a transformative journey for Giatec, leading to the development of SmartMix.

Initially, SmartMix launched as a mix optimizer, focused on enhancing the efficiency of concrete mixtures. However, as we delved deeper into the intricacies of concrete production, it became apparent that optimization alone was insufficient. We recognized the need for a comprehensive platform to centralize all performance data because the current ready mix operations’ infrastructure would not support the data access and quality needed. This underscored the importance of ensuring accurate and robust data inputs to drive meaningful insights and optimizations.

The Giatec SmartMix Solution-The Right Mix, Every Time!™

Empowered by insights from our concrete artificial intelligence program, Roxi, SmartMix is a groundbreaking solution for transforming concrete operations. Unlike conventional methods, SmartMix is the first AI-powered material management system to integrate directly with your current operations and give you full visibility of your mix performance in real time. Its predictive capabilities enable proactive risk mitigation, helping prevent potential issues before they impact project timelines. Moreover, through optimized mix designs and reduced material waste, SmartMix minimizes carbon emissions and resource consumption, contributing to environmental sustainability. SmartMix isn’t just another software – it’s your economic competitive advantage, as your biggest driver of profit is effective material management. With AI-powered precision, SmartMix empowers producers to stay ahead of the curve in an increasingly demanding industry.

Ready to explore the possibilities of artificial intelligence in concrete? Tune into our ‘Building Better with AI‘ mini-series to learn more about Roxi and follow Giatec’s exciting journey with artificial intelligence!