In April 2019, a South African construction company specializing in complex projects began experimenting with Giatec’s SmartRockTM sensors on a major arch bridge project. This bridge would be a fundamental infrastructure improvement to the Western Cape region. Historically, the region is hit by floods where over-topping events can happen. This important tourist route was closed due to these unfortunate events several times. While being localized in this region, flood-damaged repairs were often undertaken with direct impacts on the local economy, due to traffic disruption. The new bridge will ensure that there is no more interruption to the traffic in the region, ultimately benefiting the local economy, and ensuring regionally important tourist routes stay open.

One of the challenges during the construction of this project was to keep the previous bridge open to traffic. The solution was to start the construction on the side and keep the old bridge open. Therefore, an efficient schedule became even more important to the project objective.

Details of the New Arch Bridge

The new bridge has a tied-arch structural form with a single span of 370 ft (113 m). Utilizing a high strength concrete of 50 MPa (7250 psi), the bridge will also have high durability. The arches had a design strength of 50 MPa (7250 psi) and very high cement content, plasticizers were added to the concrete based on the job site setup. Upon achieving the design strength of 50 MPa (7250 psi), the forms could be stripped, and anchor plates placed to withhold the new segments. As the whole operation was conducted from all corners of the bridge; achieving the target strength was critical to the job site schedule.

How to Measure the 50 MPa Target Strength?

Historically, the construction industry utilizes cylinders or cubes cast on-site to perform critical operations. Depending on the country, these samples can be either cured in the lab or the field. Yet, the concept of field cured specimens is not widely utilized in South Africa, being more common in North America.

In countries where field samples are not standardized, lab samples are the choice – as was the case on this project. To decide to strip the arches’ forms, results from lab cubes were necessary. Nevertheless, relying on lab specimens can be overly conservative, especially in mild weather conditions where the in-situ concrete strength can have a much more accelerated pattern, due to the concrete mass effect (FAQ).

By utilizing the maturity method associated with SmartRockTM technology, contractors throughout the world can check concrete strength in real-time and perform critical operations much faster, especially when compared to traditional lab/field specimens.

Pushing the boundaries of the region’s construction technology, the team decided to test and verify the benefits of the maturity method and check its efficiency. With a cost of 600,000 Rands (35,800 USD) per month just for labor work, any project schedule reductions would generate immense savings. These potential savings become even greater when considering equipment rental and energy savings.

To examine the benefits of using SmartRock technology and the maturity method in future projects, the team conducted a thorough test, embedding the sensors at key points on the bridge.

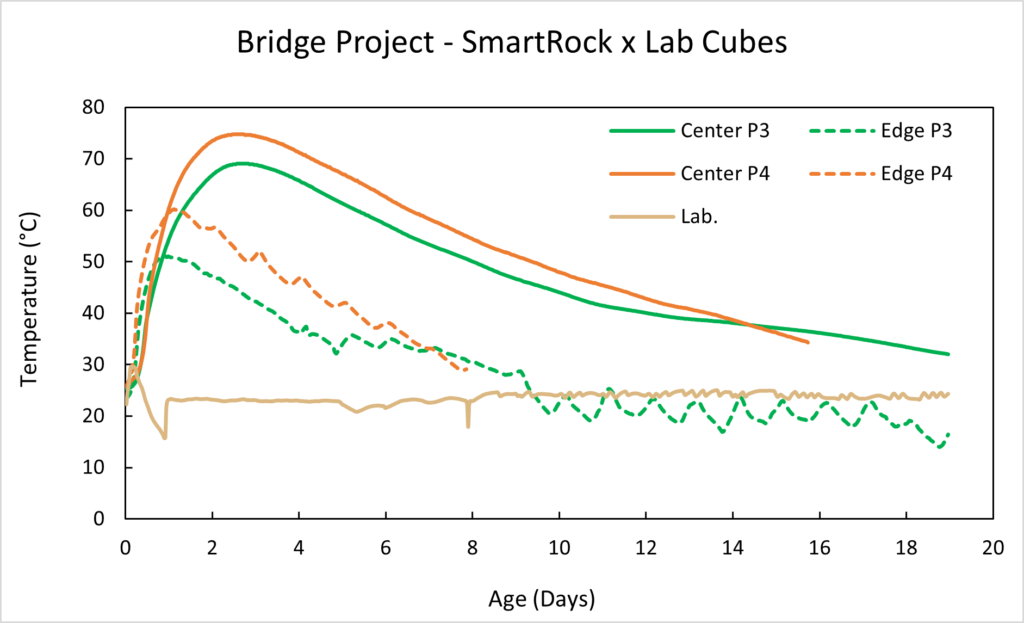

By placing the sensors in the center and on the edge of the arches, strength development was measured at different locations of the concrete element. The sensor placed at the edge captured the lower temperature profile, and therefore lowest strength gain. While the ones placed in the center of the arches measured the point of highest temperature and strength gain. By monitoring these locations, the real strength in the concrete element at a critical location was measured. This is only possible with sensors as lab samples cannot reproduce the real curing conditions of the concrete element.

Outlined below is the difference in the temperature profile of sensors on two different pours and the temperature in the concrete cube.

It was clear to the team that the same mix design when measured in different conditions would gain strength at various rates. With the temperature profiles outlined above, they were able to observe and understand why cubes typically have a lower strength gain when compared to the concrete element.

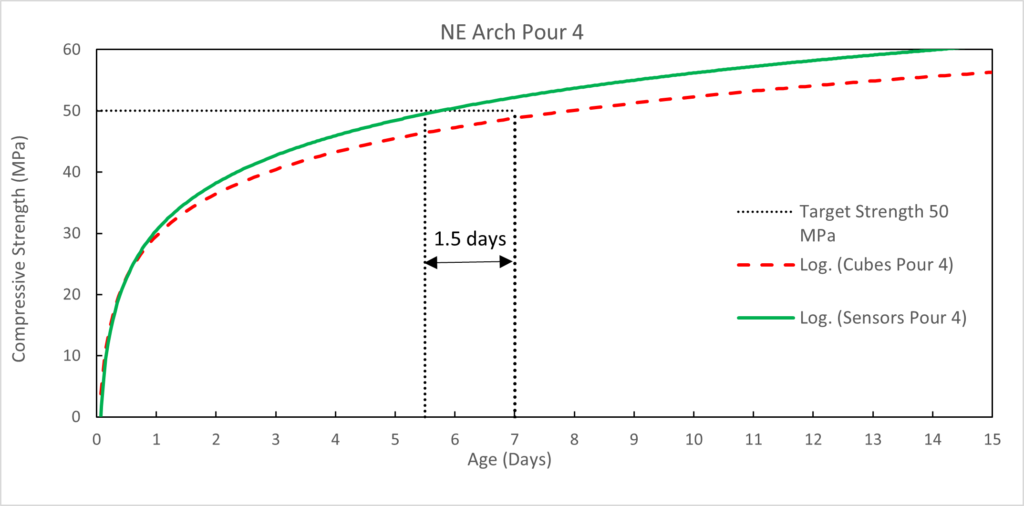

By setting up a maturity calibration (Maturity E-book), using and interpreting the data from the SmartRock sensors, they concluded that the savings could range from 1.5 to 2.5 days per section cast. One of the examples is outlined in the chart below where cubes took 7 days to achieve the targeted compressive strength, while the real concrete element achieved the same result in 5.5 days, resulting in a 1.5 days savings.

From their perspective, using the SmartRock sensors in this project could potentially save them up to 14 days in their schedule. By continuously stripping the formworks earlier, operations onsite would have been much faster with an integrated system.

More than saving time (and money) with the maturity method, they also understand that this technology can be useful from a QA/QC standpoint. The SmartRock sensors confirm the real strength in the concrete element, therefore avoiding any potential damages to the structure such as cracking when critical operations are performed.