During the construction of a concrete building, an essential step in the application of flooring is the importance of monitoring the relative humidity (RH), moisture levels, and the moisture evaporation rate of your slab. If your concrete contains excess moisture and high RH levels this can lead to disastrous flooring failures, resulting in costly repairs and liabilities. But what exactly is the difference between relative humidity and moisture and why should you care?

Relative Humidity vs. Moisture

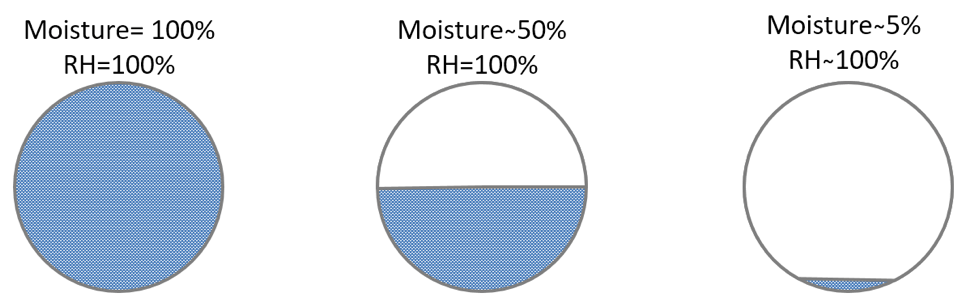

Relative humidity (RH) is often mistaken for moisture; however, these terms measure two different characteristics of concrete. Moisture content represents the amount of water in liquid form, while humidity levels represent the amount of water in vapor form.

Simply put, relative humidity represents the amount of water vapor that is present in the air in comparison to the amount that the air can hold.

To better understand the concept of relative humidity, imagine a glass of water that is sealed.

- If the glass is full of water, the moisture level and the relative humidity level will both be 100%.

- If half of the water is removed, the amount of moisture is now at 50% but RH is still at 100% because the air is still fully saturated with water.

- Now, remove almost all the water from the glass. With lower moisture content, the RH value will decrease as the air is no longer saturated.

The significance of Relative Humidity in Concrete

Even though your concrete may look dry on the surface, that doesn’t necessarily mean it is dry throughout. There may still be sources of water within your concrete in the form of relative humidity. According to ASTM F2170, when drying, concrete slabs have lower moisture levels near the surface and higher levels towards the bottom of the slab. Therefore, measuring RH levels at 40% depth of the slab (20% depth if drying on two sides), is more representative of the overall humidity conditions of the concrete.

Multiple factors can influence the amount of moisture in a concrete slab, thus contributing to high RH levels for up to six months or more after concrete is poured. Sources of moisture in concrete:

- Wet curing;

- The initial amount of water in the concrete (from a high water/cement ratio);

- Ambient conditions such as high ambient relative humidity, cold temperatures, additional sources of water, and limited air movement;

- The use of pozzolans, such as silica fume, which tend to retain water and take longer to dry; and

- Missing or inadequate moisture barriers in a slab on grade, causing outside moisture to penetrate the slab.

When flooring is installed and sealed too early, and not given enough time to dry, an excess of moisture is trapped inside the concrete. This water will try to evaporate, leading to pressure buildup in the concrete below the flooring which can cause damage and deterioration of your material.

Typical concrete failures due to relative humidity include:

- Delamination of the floor adhesive;

- Blistering of the epoxy coating;

- Re-emulsification of the adhesive (stain); and

- Curling, cracking, or bubbling of flooring materials

Prevent Flooring Failures with Concrete Relatvie Humidity Meters

To avoid these failures from occurring, a variety of test methods are used to determine the amount of moisture in concrete before installing flooring. From the 1940s to today, many contractors have relied on surface-based methods for monitoring or evaluating relative humidity levels and moisture content. This includes anhydrous calcium chloride (CaCl) testing, the hood method, the plastic sheet method, and the use of hand-held moisture meters. However, with these techniques, moisture is only measured at or near the surface of the concrete, and RH levels within the slab are not taken into consideration. These testing methods therefore do not give a reliable and accurate assessment of the moisture and relative humidity levels of the slab.

That is why in-situ RH testing has become the new standard for flooring applications. By using methods that analyze the moisture level within the slab, more accurate and reliable RH readings are available. This will allow you to determine the ideal time for placing your flooring.

Probes and wired sensors are examples of these in-situ methods. However, these techniques require you to drill multiple holes into your slab and continuously monitor the condition of the flooring, taking up time and costing money. In addition, drilling a hole in the concrete floor would change the flow of moisture, affecting the accuracy of RH measurements. That is why more and more contractors and project managers have turned to wireless relative humidity and temperature sensors, like BlueRock.

Place Your Flooring with Confidence Using This Wireless Relative Humidity Sensor

BlueRock™ is the most advanced wireless relative humidity and temperature sensor on the market. The sensor is fully embedded in your concrete (secured on the rebar) to measure internal RH and temperature variations overtime. Unlike current time-consuming methods that measure only one data point at the time of testing, this wireless sensor continually collects data. This information can be used for quality control and quality assurance purposes, allowing you to optimize the time in which you place your floor covering material. It also helps monitor:

- Drying levels in concrete floors,

- Effectiveness of curing conditions,

- Optimization of flooring installation,

- Water penetration in concrete, and

- Relative humidity gradients.

Interested in measuring relative humidity and temperature of concrete? Learn More Here!

Editor’s Note: This post was originally published in June 2018 and has been updated for accuracy and comprehensiveness.

6 Responses

It was interesting when you talked about how moisture levels in concrete can change up to six months after it’s poured. My husband and I need to find a contractor to put in a large concrete patio in the backyard of our new home before this summer. Asking about humidity in the concrete should help us find a knowledgeable contractor for the job, so thanks for giving me the idea!

You can prevent flooring failures also with Vapor Barrier, special epoxy or polyurethane primer.

Understanding RH in concrete

… cannot be done with your “explanation” above! You have to explain that

– RH above a curved water meniscus slower than 100 %; lower the more curved the meniscus is,

– curved menisci occur in porous materials when they are dried; the pore water is bound in smaller and smaller pores by menisci.

You should also show the relationship between moisture content and RH in a material. This is done with a (de)sorption isotherm. The shape and magnitude of such an isotherm depend on the pore size distribution of the material. Consequently, it is different for different concretes.

Lars-Olof Nilsson, Moisture engineering institute

Thanks Dr. Nilsson for your constructive comment and contribution to this blog post. It is, indeed, understood that the relationship between moisture content and RH (adsorption/desorption isotherms) is not a unique one and does depend on concrete pore size distribution. One can obtain such adsorption/desorption isotherms empirically (Xi et al., 1994) or using a knowledge of the pore size distribution, through a simple Kelvin’s law and Brunauer-Skalny-Bodor (BSB) model. A further complication in such isotherms occurs from the associated hysteresis observed (presumably due to an ink-bottle effect) which can be predicted through, for instance, Mualem’s or Rubin’s model. It would, certainly, be beneficial to present Kelvin’s effect or the influence of the water meniscus curvature on vapor pressure and, subsequently, the equilibrium between vapor and liquid phases.

Nevertheless, it has to be noted that the primary objective behind the vast majority of these blog posts is to simplify some of the common concepts and not to provide an exhaustive summary of the state of knowledge. A knowledge of the aforementioned illustrations is typically not available within the construction industry (and in fact a number of other practical fields dealing with porous materials). This, generally, provides a challenge in generating content that is both informative as well as simple for readers with little to no background on such topics. For a more scientific and globally valid discussion of such phenomena, the reader can refer to the relevant textbooks or articles (e.g. Daian, J. F. (2014). Equilibrium and Transfer in Porous Media 1: Equilibrium States. Hoboken: Wiley.)

If you would like to contribute to our daily blog posts or suggest some ideas for future articles with a more technical content, yet relatable subjects to non-academic readers, feel free to contact us at knowledge@giatecscientific.com, we would certainly be glad to publish your article on our blogpost page.

With the increase and demand for more housing, in a shorter period of time, coupled with the use of laminated flooring systems, the failure rate of these flooring systems, being MDF or Ply based, or vinyl, has increased dramatically.

We are al aware of the need for more housing, but left unchecked/regulated, without describing a minimum time lapse and testing for moisture content, prior to being allowed to laying a floor on concrete, will only result in product and possible concrete base failure claims against builders to rise in a very short period of time.

This is already being seen in ten year old homes that have been fitted with carpet. Upon removal of the carpet and under, moisture build up causing mould is clearly visible. This in it’s self is a concern for the health and well being of both the occupants and the installers.

Nice article….. Thanks Sara…