If you want to evaluate and select from the plethora of concrete temperature thermometers available in the market, this is the right blog for you. Before we dive into suggesting some of the best concrete curing thermometers we have come across, let’s go over a few essential questions. Learn in this blog about the importance of testing for concrete temperature, why it may prevent structural damage, and how opting for the correct concrete thermometer may enhance and simplify your project.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Concrete Temperature: Too High or Too Low?

The ASTM C1064-86 prescribes that concrete temperature must remain between 80.1oF – 95oF or between 26.7oC – 35oC. However, this can change according to project specifications. If the concrete mix is poured at a higher internal temperature, it runs the risk of encountering several problems. One of those is that your concrete could crack due to quick and premature evaporation. Alternatively, pouring the concrete mix at a temperature lower than 25oF could make the concrete freeze. This could result in multiple types of problems, including the concrete becoming severely brittle.

All in all, if your concrete temperature is too high or too low, your project is vulnerable to damages that are time-consuming, expensive, and simply avoidable.

Click here to read more about why concrete temperature testing is important during extreme weather!

Commercial Concrete Thermometers

Below, we review a few concrete temperature thermometers that may be ideal for implementation in your next project.

SmartRock®

The concrete testing device manufacturer Giatec offers SmartRock wireless sensors. They comply with ACI and work under the approval of the ASTM C1074. The sensors are fully embedded in the rebar and do not require wires or testing field-cured cylinders. They are easy to use and allow for quick decision-making onsite. This device is also a type of maturity meter. Its dual temperature capability allows the user to closely monitor temperature differentials between the core and edge of mass pours.

The SmartRock app helps you tag sensors quickly via a QR code. Users can receive proactive custom alerts and smart notifications, and provide multiple-company access to project data. The sensor sends data wirelessly to the cloud, and with Giatec 360TM, users can get alerts to follow thermal control and curing plans. Giatec 360 is a web-based dashboard that allows you to manage concrete pours. It allows the prediction of concrete temperature, analysis of temperature differentials, and setups of pour thresholds.

HardTrack

Provided by Wake, Inc., this durable temperature monitoring (per ACI 207.4R-05) device offers both handheld and remote wireless versions. This allows the users to collect concrete temperature logs onsite and offsite. Their sealed wireless concrete temperature loggers contain their own wireless radio frequency identification device (RFID), a chip, and either an internal temperature sensor or an external sensor probe. In addition, they include a remote logger with a cloud connection and one ambient sensor, as well as 4-26 sensor connections allowing external probes to connect with an available lead.

Sensohive

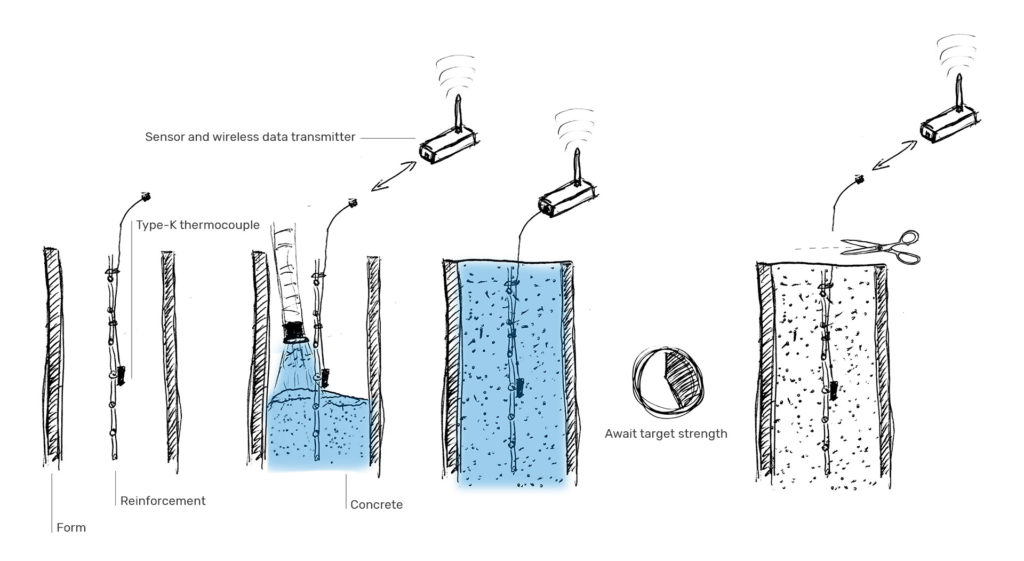

Sensohive’s Maturix uses thermocouple sensors for monitoring concrete temperature. One end of the thermocouple wires is embedded in the concrete. The other end needs a connection to a node, and each wire needs to have a separate node. The nodes record the concrete temperature data and send it wirelessly to the cloud.

HOBO

ONSET’s HOBO provides multiple thermocouple wires that contractors can connect to a HOBO box that goes outside the concrete. It includes a regular logger which records the data that can be processed on a computer. What’s more, it has a wireless logger that records and sends temperature data via Bluetooth to a mobile device. This device has compact, weatherproof housing with built-in mounting, making it compatible with harsher climates. Their free HOBOconnect app lets users observe data in real-time.

Myers Dial Face Concrete Thermometer

If you need to opt for going the more analog route, the Dial Face Concrete Temperature Thermometers (25oF – 125oF/-3.9oC – 51.7oC) from Myers Construction Materials Testing Equipment might be the one for you. It is a dual-range concrete curing thermometer with a plastic protective sleeve. Additionally, another feature included with this device is an adjustable mounting clip.

Converge

Converge Mesh offers wired sensors that connect to wireless nodes. They send data to a local hub, which then goes to a cloud. Their new concrete monitoring sensor, called Signal, is a real-time wireless strength and temperature sensor fully embedded in the concrete. The concrete temperature data can also go to a local hub or mobile device and then to the cloud through a cell network.

Click here to read more about monitoring concrete temperature with wireless sensors!

How to Choose The Right Concrete Thermometer for Your Project

As you can see, there are multiple concrete monitoring devices at your disposal. They range from wired thermocouples and traditional analog thermometers to handheld options and wireless temperature sensors. The concrete thermometer you pick ultimately will depend on a range of factors. They include project specifications, preferring to collect concrete temperature logs onsite or offsite, and compatibility of the project with wired or wireless methods.

In 2024, concrete thermometers continue to be a cornerstone tool for engineers, to facilitate the measurement of concrete temperature and ensure adherence to standards. However, the emergence of innovative concrete sensors like Giatec’s SmartRock combats the limitations of traditional thermometers, especially in their ability for remote monitoring and real-time data acquisition. This advancement enables engineers to efficiently and conveniently monitor concrete strength from anywhere, at any time.

Note: All company, product/service names, and brands used in this article are the property of their respective owners. This article is intended to be used for informational purposes only.