Every year, the construction industry goes through a recurring cycle. During summer, construction worksites explode in number and activity. This is the time when concrete strength development occurs at a steady pace. The summer weather contributes and does not slow concrete strength gain. This blog will walk you through some methods commonly used to ensure strength, like a concrete heat blanket. It will also discuss how the maturity method can reduce heat-curing costs.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

The Concrete Heat Blanket Method

Weather conditions largely influence concrete strength on-site. When it is hot, concrete can maintain the expected strength gain and critical operations can be done faster. Formwork can be stripped, lanes can be opened, cables can be tensioned, etc. However, it is when temperature drops and cold weather takes place, that the coin flips. Without proper actions, construction delays are certain, as the concrete will take longer to achieve target strength.

For that reason, projects typically adopt the use of a concrete heat blanket to ensure concrete strength development. In turn, this will maintain the project schedule. Moreover, these types of heaters are a good method to ensure that the concrete structure meets the minimum quality and durability requirements. For instance, according to ACI 306 – Guide to Cold Weather Concreting, item 3.2, concrete protected from freezing until it attains a compressive strength of 500 psi (3.5 MPa) will not be damaged by exposure to a single freeze/thaw cycle.

Want to learn more about cold weather concreting? Check out this blog!

Concrete Heat Blanket’s Purpose

The primary objective of a concrete heat blanket is to provide a minimum ambient temperature so that concrete on beams, columns, and slabs acquires enough strength. Heaters also require the use of tarps or blankets to prevent the hydration heat from dissipating. However, this equipment needs to be carefully placed to properly transmit the heat to the concrete. This ensures that the concrete is gaining enough strength for the job site’s different purposes. For example, if you want to remove formwork, a project might have 3,000 psi (20.7 MPa) as a target. Until your concrete reaches this strength, operations cannot continue.

So, how do contractors and construction companies throughout the world (especially those in the Northern hemisphere) deal with this challenge?

The Field-Cured Cylinder Factor

One way to deal with this challenge is to place heaters and field-cured cylinders in the same location, meaning close to the concrete element. By following this process, one can (with a high conservative range) be sure that the concrete has sufficient strength to move forward with job site operations. Nevertheless, this process is time-consuming and sometimes not realistic. This is because cylinders are small samples and do not represent the real behavior of the concrete element.

The picture above shows an example of cylinders that are not stored properly and have improper finishing. Therefore, they are not representative of the actual behavior of the concrete element. Additionally, sometimes the cylinders are placed right next to the heater, which does not represent reality.

Another point is that any job site is subjected to external factors that influence the concrete strength gain. This is even greater during the cold weather season. Heaters could stop working due to power outages, tarps or the flying off of blankets. Still, contractors would use concrete cylinders as the most commonly used measuring process.

Does the mix design behave the same in a field or lab concrete cylinder as the actual concrete element?

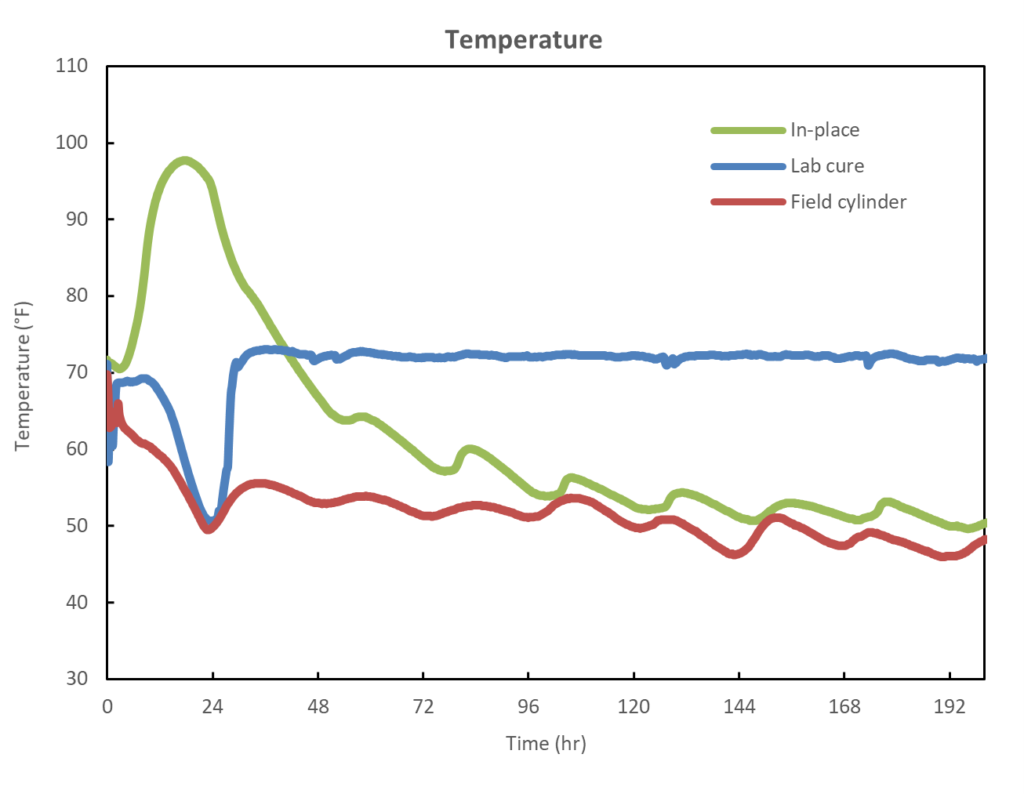

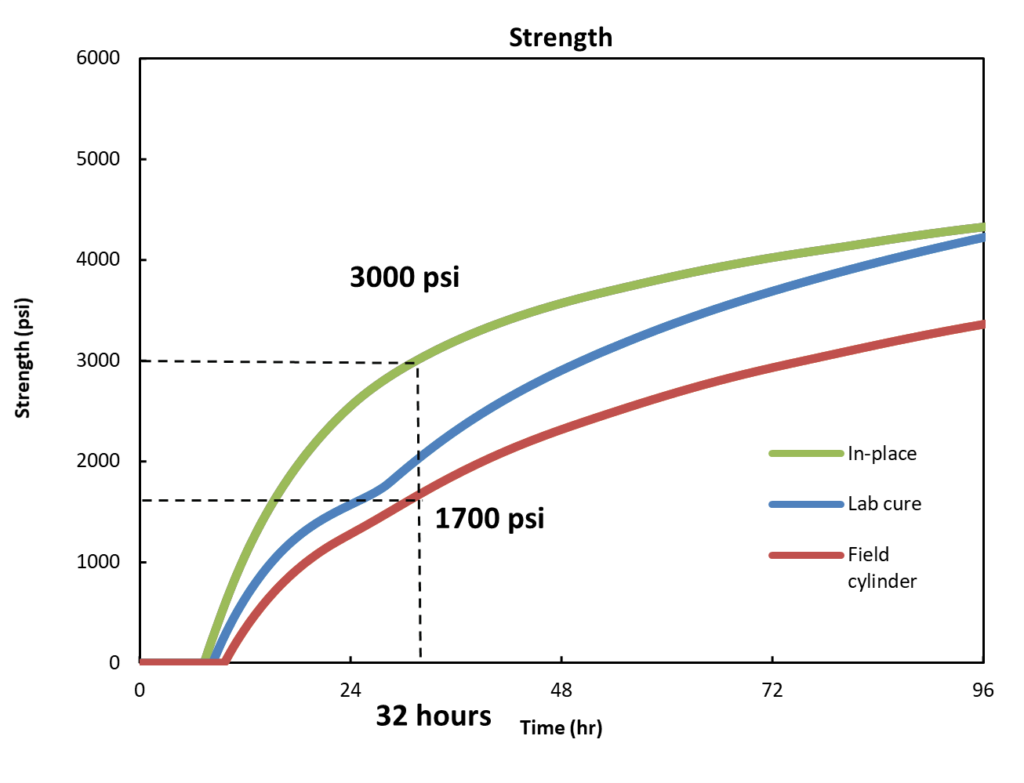

One can use the same mix design to cast field-cured, lab-cured cylinders and the concrete element. However, we can never expect the same results in strength if the curing conditions and hydration process are different from one to another. The chart below represents the temperature and strength of the same concrete, under different conditions: in-place, lab-cured and field cured.

Analyzing the data above, it becomes clear that temperature has a major effect on concrete strength development. A deeper look shows that at 1.5 days the in-situ strength is at ≈3,000 psi (20.7 MPa), yet the field cylinder is at ≈1,700 psi (11.7 MPa). This is where the differences between the conditions are notorious. In other words, if the job site were to use field cylinders to perform the critical operations, the process would take almost twice as long as by measuring the in-place strength.

Examples such as above are where the maturity method plays a great deal and helps to save time and money. With maturity meters installed in the concrete element, one can obtain more accuracy by tracking down the real strength development. Maturity meters will not only take into consideration the concrete mix but its true behavior in a large element and its higher hydration process.

Want an in-depth explanation of the maturity method? Check out this blog!

Cold weather concreting can bring extra costs because of the potential for lower productivity and the need for additional products such as concrete heat blankets. However, according to ACI 306 Guide to Cold Weather Concreting, it will also allow a project to stay on schedule.

But How Can Maturity Help Me Reduce Heating Costs?

When contractors wait for the call from the lab to proceed with operations, they need to keep the heaters on to ensure the concrete continues to gain strength. This can take longer than expected.

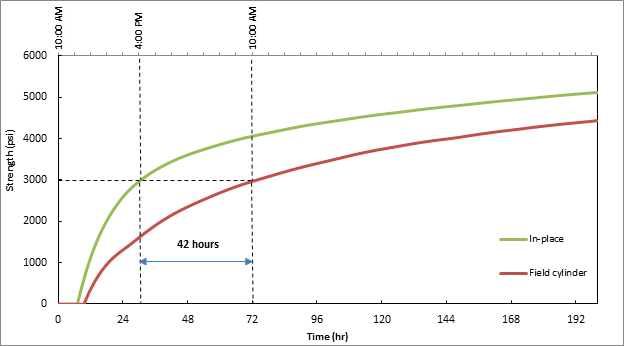

Let’s go back to the chart with the different temperature profiles and only analyze the field cylinder vs. in-place strength. The goal is to achieve 3,000 psi (≈ 20 MPa) to strip forms and continue with job site operations. The pour ends at 10 am on day 0.

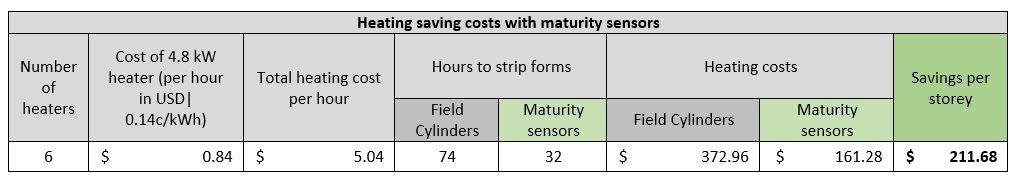

On the one hand, field cylinders would testify that your 3,000 psi (≈20 MPa) target will be reached within 72 hours or at 10 am three days after placement. On the other hand, if maturity sensors were used, the same target would be achieved within 30 hours, or at 4 pm on the next day after the pour. In both cases, heaters would be kept running until target strength was achieved. However, the difference would be 42 hours. Translating these hours saved into USD, the job site could save $211.68 per storey by using maturity sensors.

Other Uses for Maturity Sensors During Cold Weather

Other than the savings outlined above, a maturity meter can play an important role when controlling heaters on-site. When associating the SmartRock® technology with the SmartHub™ solution, contractors throughout the world have 24/7 access to the concrete’s performance and ambient conditions. SmartRock sensors can be installed at a location near the heaters to check if the units are performing accordingly throughout the night.

This application of the sensors saves not only unnecessary travel to the site but also brings peace of mind to make sure no power outages turn your heaters off. Therefore, you can always be sure there was no disruption in the strength gain or freezing of the material. It also allows you to act proactively to prevent damage to the concrete element and ensure its quality and durability.

If you would like to know more about the SmartRock® solutions and their application to cold weather conditions, check out this blog.