Giatec continues to uphold the value of bridging the gap between academic research and sustainable construction on the jobsite. Every year, we recognize civil engineering students, researchers and faculty across Canada and the U.S. with the Giatec Best Paper Award for Sustainability in Construction. Below is a summary of the 2021 winning paper submitted by Ying Wang and her team, Strength Activity Index and Bulk Resistivity Index Modifications That Differentiate Inert and Reactive Materials in Cement and Concrete Composites. Find how you can join the list of winners and showcase your research to a global audience of industry experts while receiving a monetary award of 1,000 USD here.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Research Background

Portland cement is often replaced by supplementary cementitious materials (SCMs) in concrete to increase sustainability (reducing CO2 emissions due to lower cement contents) and durability (mitigation of alkali-silica reaction, reduced sulfate attack, and reduced chloride penetration). Fly ash and natural pozzolans are specified using ASTM C618/AASHTO M295, and an important part of this specification is the strength activity index test (SAI), which dictates that a mortar mixture with 20% SCM replacement should reach at least 75% strength of the control mixture at either 7- or 28-days. The SAI is a potentially flawed test as inert materials are known to be able to pass the test. The early testing age, low SCM replacement level, variable water-to-cementitious materials ratio, and low strength requirements relative to the control mix, all contribute to the inability of the test to successfully distinguish inert and reactive materials. With the continuing limitations in the availability of conventional fly ashes, it is critical that specifications and their proposed test methods accurately quantify pozzolan quality and enable use of natural pozzolans and unconventional fly ashes capable of creating concrete that is sustainable and durable. Therefore, the SAI must be improved.

Bulk Resistivity as a Potential Alternative

The ASTM C618/AASHTO M295 SAI test is flawed because it measures strength under conditions where reactivity is low. Two solutions that may improve the test are to use conditions that increase reactivity or its effects and/or to use a test method that is more sensitive to reactivity. Results from our lab and from the literature have suggested that bulk resistivity could be a promising method as SCMs have been shown to increase later-age bulk resistivity and inert materials do not. Type I/II Portland cement, two Class F fly ashes, one Class C fly ash, two inert fillers (limestone (LS) and basaltic fines (BF)) were used to prepare mortars at two replacement levels (30% and 50% by mass), and two curing temperatures (23 and 50 ºC in limewater). Compressive strength and bulk resistivity were tested on the mortars at 7 and 28 days. Additional cement paste testing was performed using isothermal calorimetry and thermogravimetric analysis to evaluate hydration and reaction in these conditions.

Important Findings

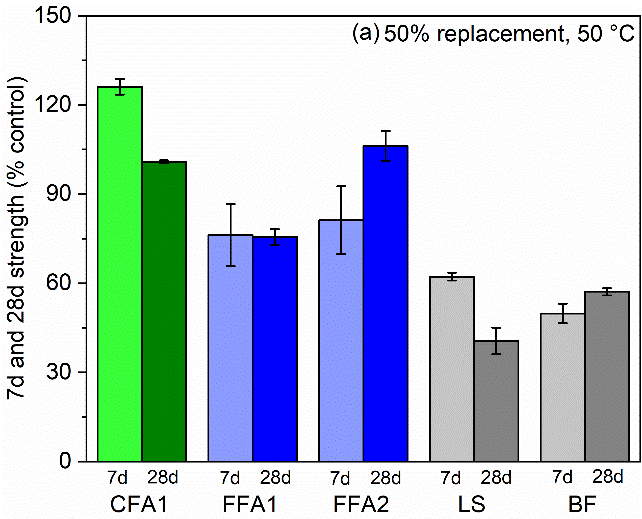

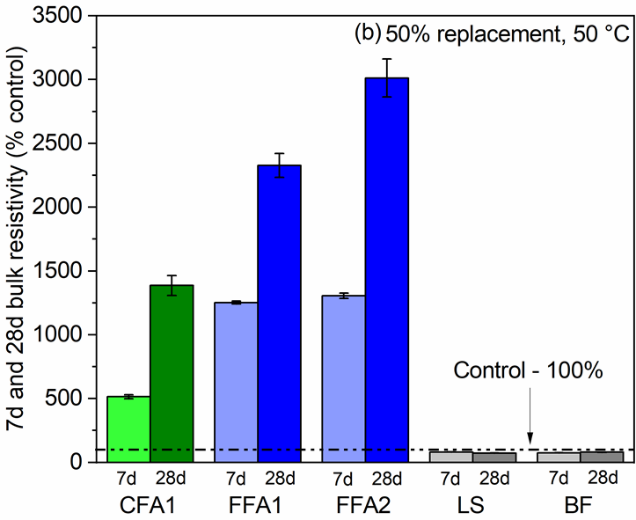

Using higher replacement levels and higher temperatures does provide improved differentiation of inert and reactive materials when using the SAI, however, the magnitude of differences is small when considering variability in strength measurements (Fig. 1a). On the other hand, higher replacements and especially higher temperatures result in substantial increases in bulk resistivity for the reactive fly ashes but not for inert materials (Fig. 1b). Therefore, the bulk resistivity index test (BRI) carried out at higher temperatures provides for clear differentiation between inert and reactive materials and it should be considered for specification in ASTM C618/AASHTO M295.

The calcium hydroxide content and heat release measured in corresponding cement pastes show that increased temperature enhances fly ash reaction but does not affect inert materials. At higher replacement levels, greater effects of fly ash reactions are manifested, resulting in better differentiation from inert materials than at lower replacement levels. Bulk resistivity is more sensitive to the increased reaction when compared to strength. The mortar bulk resistivity values are correlated to paste calcium hydroxide contents and the results suggest potential pore depercolation at higher temperatures for reactive materials.

Fig 1. (a) SAI modification and (b) BRI modification results for 50% SCM replacement level at 50 ℃.

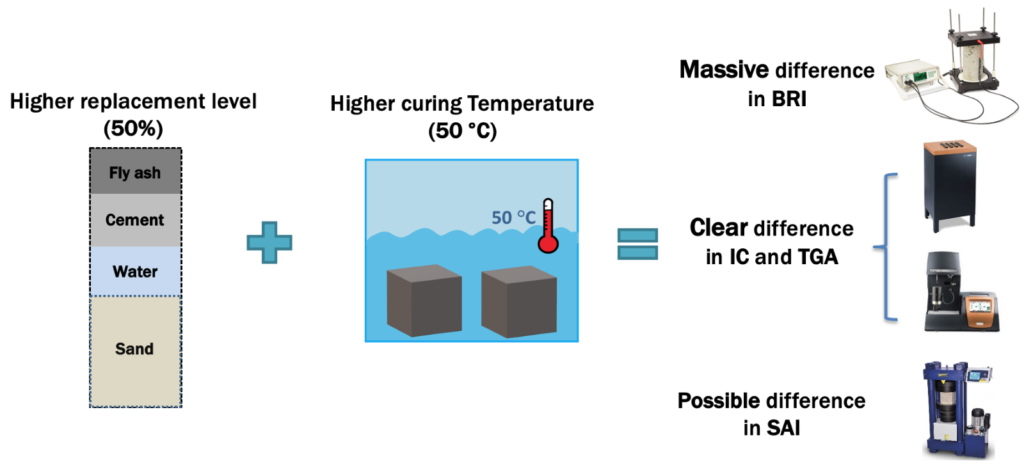

This work was carried out as part of a funded NCHRP project on modifying US fly ash specifications to allow for the incorporation of unconventional fly ashes. The results clearly show that the BRI is a better indicator of reactivity than SAI and it can be used to replace the SAI in ASTM C618/AASHTO M295. A graphical abstract of this work is shown in Fig. 2. BRI robustness and round robin testing are planned in the near future to validate our findings and to identify optimal parameters for the ‘standard’ BRI test.

Fig. 2. Graphical abstract of our results showing the BRI test.

The results of our research were published in a paper titled Strength activity index and bulk resistivity index modifications that differentiate inert and reactive materials in Cement and Concrete Composites. We are truly delighted and honored to receive the Giatec Best Paper Award for this publication. We hope that our findings will improve SCM specifications and lead to greater utilization of novel SCMs and (more) sustainable and durable concrete.

Ying Wang, Lisa Burris, Christopher R. Shearer, Douglas Hooton, Prannoy Suraneni

Lead author, Ying Wang, is a Ph.D. student in Civil and Architectural Engineering at the University of Miami. She can be contacted at yxw1218@miami.edu.