Consistent temperature tracking is one of the most crucial steps after a concrete pour. By monitoring the temperature, you will be able to create an optimal curing environment. This will improve the overall strength of your concrete. According to ACI 301-16 standards, maintaining temperatures is also critical for the success of the hydration process. Therefore, before you get ready for your first pour, you need to decide what concrete testing equipment you will use to measure the in-situ temperatures of your concrete elements. This decision will be even more important if you are working on a mass concrete element or in extreme weather conditions. By having a plan and keeping temperatures consistent, you can improve the overall durability of your structure and reduce frustrating thermal cracks.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Learn why concrete temperature monitoring is right for your projects

When Do You Need a Thermal Control Plan?

To begin, it is important to know that if you are working on a mass concrete element, you must have a thermal control plan. Given the mass effect of these projects, the concrete core can have a high temperature, while the surface tends to be cooler because of its exposure to the external environment. However, if the temperature differentials are too high, the tensile stress of the concrete will exceed its tensile strength, leading to cracks. A thermal control plan considers things such as the heat output of the concrete mixture. It sets a maximum temperature at placement and explains how you are going to limit risky temperature differentials.

Another situation that requires close temperature monitoring is a cold weather project. Similar to mass concrete, extreme temperatures increase the risk of thermal cracking. Insulation and cooling pipes are two examples of how you can maintain a consistent temperature. Nonetheless, it is important to ensure you are heating and cooling the correct amount. Otherwise, your efforts will not be successful.

Learn how to avoid 7 cold weather concrete mistakes here!

What Is the Best Concrete Testing Equipment?

Options for monitoring concrete temperature include thermocouples, wired temperature loggers, wired concrete sensors with an external wireless transmitter, and fully embedded wireless concrete sensors. Here is a brief overview of each option in concrete testing equipment, and the pros and cons to help you with your planning.

Thermocouples

A concrete thermocouple consists of two wires of different metals that connect at one end to form an electrical junction. One can purchase them in a bundle and cut them into custom lengths. The reason why is to account for the distance between the location where you want to monitor the temperature of your slab and the location of the measurement equipment. At one end, the two thermocouple metal wires are twisted together, and at the other, they are connected to a plug. The wires must always stay connected to the external device. Usually, this is where the measurements are displayed. At the completion of measurements, the device can connect to a computer to download the data.

Pros

- This method is relatively inexpensive

- As it is an older and less complicated method, it requires less training

Cons

- Time-consuming to install and use

- Low accuracy rate

- Some require manual data analysis, which is labor-intensive

- Wires may be damaged or cut while on-site

Wired Concrete Temperature Loggers

This concrete testing equipment has an electronic circuit board that contains a coin-size battery with an onboard thermistor for temperature measurement. One can record measurements and store them on this circuit board at pre-defined intervals. After concrete pouring, users can connect their hand-held unit or data logger to the end of the wires to download the recorded temperature values.

Pros

- More rugged than thermocouples and less prone to damage

- The external logger is only used to download data, so it is not regularly exposed to potential damages

Cons

- Limited-shelf life

- Like thermocouples, the wires must be properly labeled so they do not get cut or lost

- Difficult to install

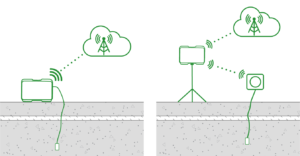

Wired Concrete Sensors With External Wireless Transmitter

Wireless data transmitters remove the hassle of having to collect data with an external device and use a computer to download it. These are a type of concrete testing equipment that use external units connected to the end of the wires coming out of concrete to store and transfer the temperature measurements over a wireless network.

Pros

- Data analysis can be done automatically on the cloud to generate custom alerts and notifications for project managers and superintendents even when they are not on the jobsite

Cons

- The wire connection to the external unit is still prone to cuts

- The wireless unit is prone to damage in a harsh construction environment

- It is a complex system and can be challenging to install

Fully Embedded Wireless Sensors

These are self-contained wireless concrete sensors and loggers that are fully embedded in the concrete. The temperature measurements are stored on the sensor, and that data can be downloaded through various wireless communication protocols. Different products will have their own way of downloading data. Some options require you to be on-site to download any data. However, if you have a wireless local hub, you will be able to access it without even visiting the jobsite.

Pros

- Unlike wired systems, the sensors are not prone to potential damage to the site

- The sensor securely holds data while in the concrete and users can download it with confidence at any time

- The installation and data collection are relatively simpler and faster

- If you have a wireless unit, you do not need to maintain external units, which could lower your overall cost compared to the wired sensor

Cons

- The initial purchase cost of these embedded sensors is higher than wired sensors/loggers

- The wireless signal from these sensors can only transmit data through a couple of inches of concrete. Therefore, for deeper locations, it is necessary to have a temperature measurement cable while the wireless sensor is on the rebar below the concrete surface.

Choosing the Right Concrete Testing Equipment

To summarize, if you decide to go with a fully embedded wireless sensor, there are several commercial options. These concrete testing equipment options vary in price, accuracy, and ease of use. Thus, Giatec is proud to offer SmartRock, the leading wireless concrete sensor for measuring temperature and strength. The real-time data from SmartRock allows you to decide exactly when to take measures to cool or heat your concrete, which will help you build structures faster, safer, and more economically. Moreover, by adding SmartHub, you can eliminate the hassle of visiting your site to retrieve data.

For an in-depth comparison and description of all the equipment listed, click here.

Sources

Beton Consulting Engineers

*Editor’s Note: This post was originally published in May 2020 and has been updated for accuracy and comprehensiveness in May 2022.