As global initiatives to go carbon-neutral continue to push the demand for sustainable and renewable energy sources, many are looking to wind farms as a green solution to energy needs. Wind power has been used as an energy source for centuries – from windmills grinding grain to sailboats traversing bodies of water. However, as more and more of the world depends on electricity to function, wind is now being harnessed as a source of electricity.

Wind turbines, usually grouped into “wind farms”, operate by converting kinetic energy from the air into electricity. This electricity can be used locally or directed into the power grid to fulfill more remote electric needs. Because wind farms require no fuel and create no pollution, they are becoming increasingly popular as an environmentally-friendly way to produce electricity.

How Are Wind Farms Built?

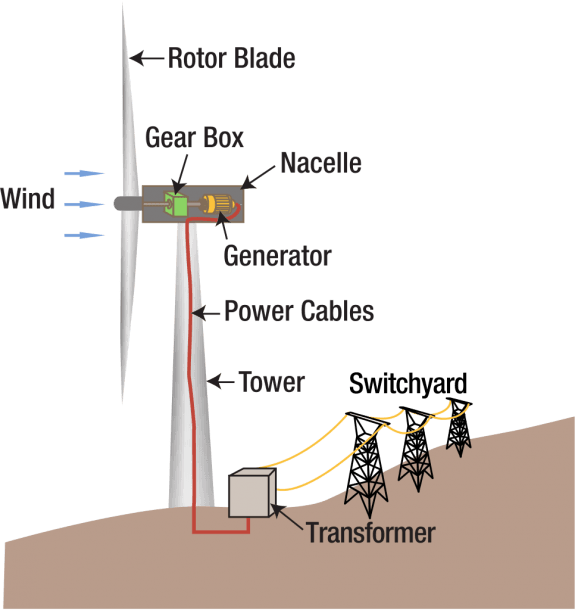

A wind turbine is composed of a tall tower with a nacelle and rotors at the top. The nacelle is a box-like structure at the top of the shaft that contains a generator, which the rotor blades power by catching the wind and spinning. The tower contains power cables that transfer the electricity to the transformer and, eventually, into the electricity grid.

This large structure often requires a sizable concrete base to support it. The construction of this concrete base can be classified as a mass concrete pour. While there are no strict volume requirements to define a construction project as mass concrete, the term encompasses any volume of concrete large enough to require measures to be taken to control the immense generation of heat that comes from the hydration of a large volume of concrete.

Monitoring Temperature in Mass Concrete

To create a stable and safe base for the wind turbine, measures need to be taken to ensure that the heat generated by the process of hydration does not cause thermal cracking. Thermal cracks may form if the temperature differential (the difference in temperature between the core and surface of the concrete) is too high. Since a larger volume of concrete generates more heat during hydration, mass concrete is at a higher risk of developing thermal cracks, which damage overall structural integrity.

Learn more about monitoring temperature differentials in mass concrete here.

To mitigate the risk of thermal cracking and gain control over your concrete, temperature monitoring is a must. There are a few different ways to monitor concrete temperature, including traditional methods like wired sensors or thermocouples. However, these methods can be cumbersome and time-consuming – involving easy-to-damage data loggers and messy lengths of wires around the jobsite. An even more effective way to monitor temperature in mass concrete is by using wireless concrete sensors.

Read an in-depth comparison of wired and wireless sensors in this blog!

The Best Way to Monitor Concrete Temperature

Rather than relying on inefficient tools to monitor temperature, contractors and project managers can take advantage of advanced technology such as the SmartRock® concrete sensor and monitor concrete temperature in real-time. These easy-to-install sensors are placed on the rebar prior to your pour and wirelessly transmit data to any mobile device. Temperature readings are taken from both the sensor body as well as the tip of the temperature cable, which can be extended deep into the concrete structure. This enables the measurement of concrete temperature in two locations simultaneously, per sensor, making it easy to analyze temperature differentials and control concrete temperature.

Once data is collected by the fully-embedded sensor, it is sent to your mobile device, where real-time temperature readings can be viewed and are updated every 15 minutes. You may also set temperature thresholds which will send you alerts in the app if these temperatures are reached.

On the topic of green energy, SmartRock’s AI Assistant Roxi ™ has also been trained to analyze concrete mixes and suggest the amount of cement needed, giving clarity into mix design and curbing the overuse of cement in mixes. As cement production is a key contributor to global CO2 emissions, Roxi’s ability to reduce the amount in a concrete mix while maintaining required strength makes her an asset to concrete producers looking to reduce cement usage, cut carbon emissions, and save money!

Read more about Roxi’s capabilities here!

Concor’s Experience with SmartRock

Concor Construction is one of the largest construction companies in South Africa. They began construction on the Roggeveld wind energy facility in 2019, a wind farm which aims to improve South Africa’s carbon footprint by supplying clean electricity to the power grid. Between the remote location and the extreme heat conditions, this project presented a challenge and, having had previous negative experiences with wired sensors, Construction Manager Marritus Bezuidenhout decided to turn to SmartRock wireless sensors.

SmartRock allowed Concor to realize significant time savings on the project: “Over the course of the Roggeveld project to date, which is about half the bases, I’d say we have saved almost a month by relying on SmartRock’s strength data for backfilling.”

Read more on Concor’s use of SmartRock here!

In 2020, Concor Construction won the Civil Engineering category in Construction World’s Best Projects for their work on the Roggevald Wind Farm.