Reinforced concrete structures have shaped our cities for thousands of years, from historical buildings stretching as far back as the Romans to present day, such as the 3-storey parking garage adjacent to the mega shopping mall a few miles from your home. As individuals living in the 21st century, experiencing historical buildings is a blessing and something we are all grateful for – success of architects’ past. These magnificent, sometimes intimidating, structures continue to be built. This includes large spanning bridges, government buildings, multi-use high rises, and much more.

Download the full Checklist now and experience smoother, stress-free cold-weather concreting like never before.

However, behind the photogenic façade lies an engineered system of reinforcement – steel reinforcement. Carefully designed, steel reinforcement is an important part of a multi-functioning system that ensures the structures’ integrity. Each reinforced concrete structure has a designed service-life – “the assumed period for which a structure is to be used for its intended purpose with anticipated maintenance but without major repair being necessary” (1).

The initial construction, specifically concrete pouring, curing, and the concrete mix design, are essential to reach or surpass its designed service-life. Further, it is important to inspect the reinforced concrete structure over time to observe any signs of deterioration, and if required, perform remediation.

Methods of Inspecting Service-Life of Reinforced Structures

The most common method for inspecting reinforced concrete structures is visual inspection. This method includes, but is not limited to, checking for cracks, delamination, disintegration, dusting, leakage, and scaling. Further details can be found in “ACI 201: Guide for Conducting a Visual Inspection of Concrete in Service”. Visual inspection reports, gathered over time, provide valuable information on the structure’s health.

However, visual inspection is just that – visual. These inspections are often supplemented with non-destructive tests, destructive tests, and other investigative techniques. The goal of these tests is to understand the condition of the concrete and steel reinforcement, thus, allowing the inspector to conclude on the structures health after interpreting the data. Defects found during visual inspection may require immediate action.

Destructive tests may include concrete coring to help determine compressive strength, carbonation depths, the presence of sulfates and chlorides, and the concrete’s pH level. These tests, especially when performed simultaneously, can provide a substantial amount of data on the concrete’s durability and the condition of the structure. Carbonation and pH tests assess the loss of alkalinity (the steel reinforcements natural protector). Sulfate and chloride sampling provide visibility on harmful agents that may exist in the concrete cover, the amount in which they exist, and their depth. The latter, chloride ingress, is the most prominent cause of deterioration in reinforced concrete in North America and many parts of the world.

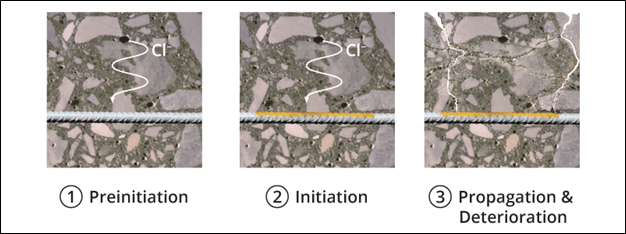

Given the significant affect of chlorides on a structure’s durability, inspectors are interested in a multitude of corrosion parameters. Figure 1 shows a representation of service-life stages for structures exposed to chloride-induced corrosion risk.

Further, correctly understanding the time for chloride-induced corrosion to occur is an important step to assess a structures remaining life. The end of service-life can be generalized as the time to cracking resulting from corrosion products formation.

What is Corrosion Rate?

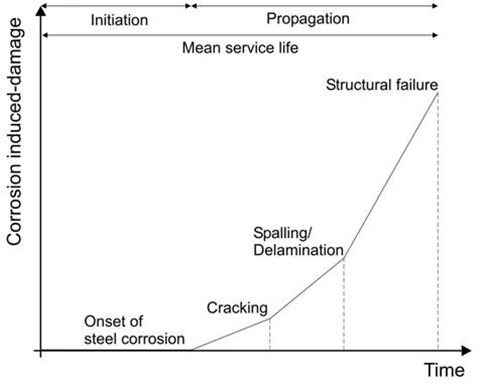

The main challenges of concrete structure inspections are to understand the severity of the corrosion, in other words where in the structure service-life are we located and when the onset of the steel corrosion started. One parameter that is very useful to know is the corrosion rate. Corrosion rate can be defined as the speed at which any metal in specific environments deteriorate (3). Figure 2 illustrates the service-life model of a concrete structure exposed to chlorides.

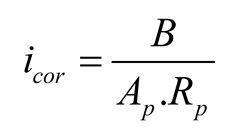

There are different techniques on the market to measure the corrosion rate of reinforcing steel, however, they all utilize the Stern-Geary equation (shown in the equation below).

The Stern-Geary equation calculates the corrosion rate by measuring the polarization resistance (Rp), which is the slope of a current-voltage plot, generally from an applied current, and the measured change in potential of the metal in an electrolyte (concrete). Ap represents the area of polarization. B is a corrosion constant calculated from the anodic and cathodic Tafel slopes (4).

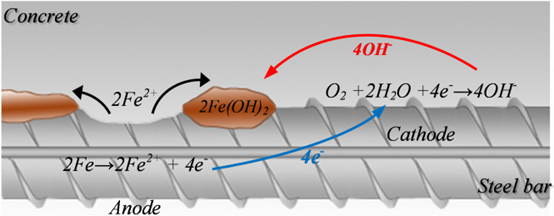

The objective of corrosion rate measurement devices, such as the iCOR®, is to measure the corrosion current on the surface of the rebar due to the transfer of electrons from anode to cathode. This is illustrated in Figure 3. Corrosion rate values are typically outputted in two units: corrosion density (uA/cm2) and corrosion rate (um/year). It’s important to note that the value being measured is the corrosion current occurring on the rebar at that point in time. It can be understood as a snapshot of the corrosion activity at a certain point in time in the structure’s service life.

What Can I Do with Corrosion Rate Values?

Generally, as an inspector, the more analysis and online concrete monitoring techniques at your disposal the better. Other techniques such as half-cell potential and concrete resistivity are often used in conjunction with corrosion rate measurements. The higher frequency of testing (within reason) the better. Performing measurements over time is critical when understanding the state of the structure and estimating its remaining service-life.

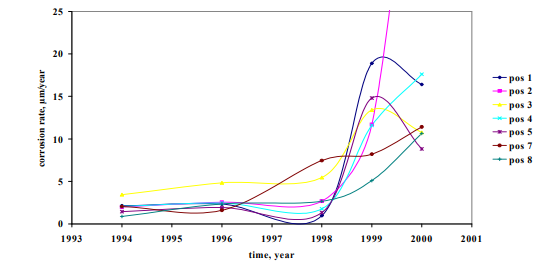

A 6-year study conducted on a highway-bridge pillar exposed to de-icing salts in Copenhagen illustrates a great example of the importance of corrosion rate testing, factors that influence measurements, and how to interpret the results (5). A portion of the study took corrosion rate measurements at the same locations over a 6-year span as seen in Figure 4. It can clearly be observed when the corrosion propagation period started.

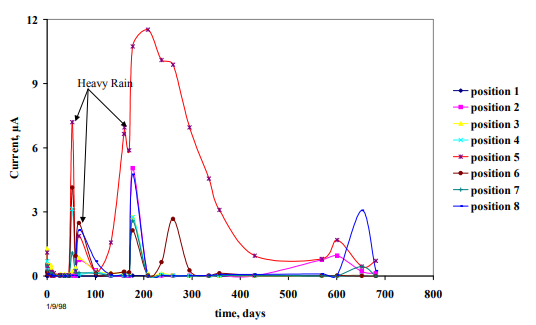

Humidity and temperature will affect the corrosion rate results. Dryer and warmer months are going to slow down corrosion activity, where seasons of heavy rain are more conducive for corrosion activity, as seen in Figure 5. Based on the factors that can impact corrosion rate values, the increase in corrosion rate over time will not always be linear. Figure 5 shows how corrosion activity can change at different time in the year.

The goal of the corrosion rate testing is to understand the speed at which the rebar is corroding and also to understand how much reinforcement diameter has been lost over time, where 20% of mass loss is a critical threshold for structural failure. In order to understand the total mass loss, it is important to know the corrosion rate activity over time. The integral of the corrosion measurements can be calculated to provide an approximation of the mass lost. It is also important to understand the time at which corrosion started to provide good estimation.

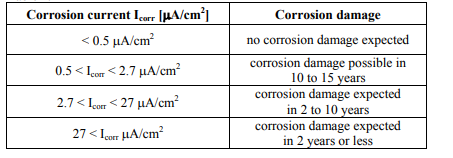

Lastly, with this data, the inspector can predict the service-life of a structure. One way of interpretation can follow the guidance of K.C. Clear (6), whose model is based on the combination of outdoor exposure, laboratory, and field studies.

Sources

- Corrosion monitoring in concrete

- Probability-based durability design of concrete structures in marine environment

- Corrosion Rate

- Measuring Rate of Corrosion of Steel in Field Concrete Structures

- Rebar Corrosion Rate Measurements for Service Life Estimates

- Measuring Rate of Corrosion of Steel in Field Concrete Structures