Roxi, the First Artificial Intelligence Program for Concrete Testing, Helps Reduce Cement Usage with Funding from Sustainable Development Technology Canada

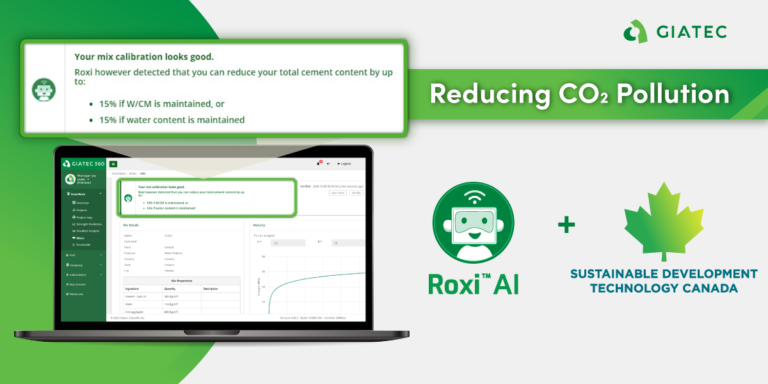

OTTAWA, Ontario, October 13, 2020 (Newswire) -Giatec, world leader in concrete testing technologies, has announced that their artificial intelligence (AI) program, Roxi, has been trained with the help of Sustainable Development Technology Canada (SDTC) funding to reduce cement usage on construction jobsites during concrete testing.

Traditionally, concrete producers do not have thorough visibility into the rate at which their concrete hardens on jobsites or in specific ambient conditions. As a result, they often add more cement than needed to their mixes to ensure specified strength targets are met. Now, Roxi provides more insights regarding the amount of cement that is needed, including the amount that can be removed without compromising the concrete’s setting time or strength development. As a result, CO2 emissions resulting from the manufacturing of concrete will also decrease. This new feature will help decrease the cost of concrete mixtures and improve profitability for producers.

Giatec received funding of $2.4 million from SDTC to help with the training, research, and development of Roxi. This is part of a $58.6 million investment SDTC made in Canadian clean technology companies to help bring clean technologies to market.

“Roxi is the type of cutting-edge technology that has the power to make significant environmental impacts by reducing cement usage while also being a cost-effective tool for construction jobs. We are proud to support the development of this novel AI-enabled cleantech, and to make sure Roxi gets the best training!” says Leah Lawrence, President & CEO, SDTC.

Funding of $800,000 was also received from the National Research Council of Canada Industrial Research Assistance Program (NRC IRAP) to support the research and development of AI applications for predictive concrete analysis.

“Our government is proud to support Canadian cleantech innovators like Giatec. With these investments through SDTC and IRAP, we’re helping businesses lead the way in building a clean and prosperous future for all Canadians.” says The Honourable Navdeep Bains, Minister of Innovation, Science and Industry.

Roxi was the first AI program created for concrete testing, built for Giatec’s patented, award-winning SmartRock wireless concrete sensor. SmartRock has been used in over 6,200 construction projects across 45 countries, giving Roxi access to millions of data points to analyze. As the first truly wireless sensor introduced to the market in 2015, SmartRock is the leading concrete maturity sensor for accurate monitoring of concrete curing and hardening. Unlike time-consuming and error-prone break tests, or cumbersome wired sensors, SmartRock uses a highly accurate ASTM-approved testing method. Together with the Giatec 360™ platform and SmartHub™ remote monitoring device, this has enabled faster, safer, and more economical concrete construction.

ABOUT GIATEC

Giatec is a global company revolutionizing the construction industry by bringing smart testing technologies and real-time data collection to the forefront of every jobsite. Giatec’s suite of hardware & software products has leveraged advanced technologies such as; Artificial Intelligence (AI), and Internet of Things (IoT), including; wireless concrete sensors, mobile apps, and advanced non-destructive technologies (NDT) to drive innovation throughout concrete’s lifecycle.

MEDIA CONTACT

Dobrila Moogk, VP Marketing

+1-877-497-6278

marketing@giatec.ca