Giatec continues to uphold the value of bridging the gap between academic research and sustainable construction on the jobsite. Every year, we recognize civil engineering students, researchers and faculty across Canada and the U.S. with the Giatec Best Paper Award for Sustainability in Construction. Below is a summary of the winning 2025 paper submitted by Dr. Soroush Mahjoubi and his team, “Data-Driven Material Screening of Secondary and Natural Cementitious Precursors.”

SmartRock® Long Range Savings for Big Projects

Want to see how you can share your research for the 2026 Giatec Best Paper Awards? Learn more here!

Research Background

Concrete is the most widely used manufactured material on the planet, and because we produce so much of it, it has a significant carbon footprint. Most of those emissions come from clinker, the binder in cement that requires energy-intensive kilns and releases CO₂ when limestone is calcined. For decades, the industry has replaced a portion of clinker in mixes with lower-carbon materials such as coal fly ash and steel slag. However, as coal plants shut down and steel recycling ramps up, supplies of these traditional substitutes are shrinking.

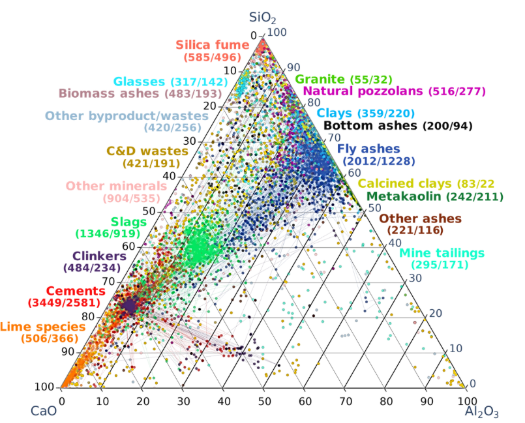

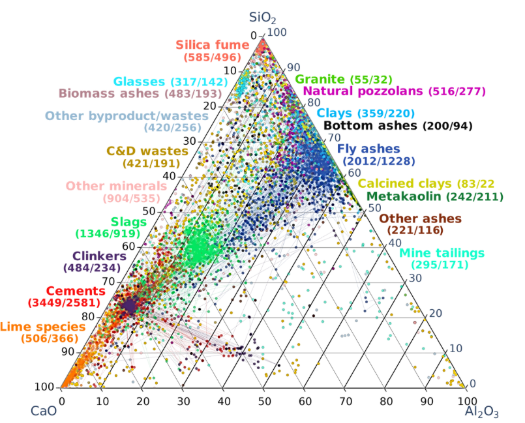

To continue reducing emissions by replacing clinker, the industry needs new supplies of clinker replacements. New research from the MIT Concrete Sustainability Hub and Olivetti Group aims to mitigate this problem with the help of artificial intelligence (AI) and machine learning (ML). The team used large language models (LLMs) to screen over 10,000 scientific papers and over one million rock samples to identify more than 14,000 potential clinker replacements, sorting them into 19 types. This approach aims to expand the pool of materials worth testing, especially those that are locally available.

Important Findings

The team’s models identified several by-products typically thought of as “waste” that have strong potential to serve as clinker replacements. These included materials ranging from biomass ashes to mining byproducts to waste glass. Additionally, in screening rock samples, the study found that many minerals worldwide could have potential as clinker replacements—many can be incorporated into concrete mixes by simply grinding them. Rock types such as ignimbrite, silicic tuff, pumice, anorthosite, and rhyolite appear especially promising and are abundant in volcanic and tectonic regions worldwide.

Beyond cataloging candidates, the research explains why these materials perform differently. Reactivity was strongly influenced by factors such as amorphous content, alumina levels, specific gravity, and calcium carbonate content. These insights provide clearer guidelines for identifying and activating future clinker substitutes.

Together, these findings suggest that a broader and more geographically diverse set of materials could support clinker substitution than previously recognized, opening the door to more flexible and locally sourced low-carbon cement blends.

Further Reading

For more details, readers can refer to the paper “Data-driven material screening of secondary and natural cementitious precursors” published in Nature Communications Materials. This study was conducted by Dr. Soroush Mahjoubi and his team and is freely available online.

Authors: Soroush Mahjoubi, Vineeth Venugopal, Ipek Bensu Manav, Hessam AzariJafari, Randolph E. Kirchain, and Elsa A. Olivetti

Lead author, Dr. Soroush Mahjoubi, is a Postdoctoral Associate at MIT’s Concrete Sustainability Hub and Olivetti Group. He can be contacted at mahjoubi@mit.edu.