A Review of Top Wired and Wireless Temperature and Strength Concrete Sensors

Move Data Center Projects Faster

As a leader in wireless concrete sensor technology, Giatec is committed to helping contractors improve efficiency, reduce risk, and gain real-time insights into concrete curing and strength. In this blog, we’ll go into a concrete sensors comparison of a range of commercially available wired and wireless solutions to support better decision-making when selecting the right monitoring solution for your thermal control plan.

Why Concrete Strength and Curing Drive Construction Schedules

In a construction project, concrete is often on a critical path. Most of the jobsite activities cannot be initiated unless the concrete that is placed for building structural elements such as beams and slabs has achieved sufficient strength (typically 75% of the specified compressive strength of concrete). If concrete is not cured properly in favorable temperature ranges (at least more than 5°C or 40°F based on ACI 306) after pouring, it is quite possible to have a slippage in the project plan and timeline due to the delayed strength development in concrete. Curing temperature is also important when it comes to mass concrete placements such as foundations. If the temperature differential between the surface and core of the mass concrete element exceeds a certain level, there is a good chance of concrete cracking due to thermal stresses. Project managers, therefore, have a thermal control plan to ensure that concrete achieves the target strength values as scheduled during the first few days after pouring concrete so they can safely move to the next steps of construction such as formwork removal or post-tensioning with confidence.

Integrating Temperature and Maturity Monitoring into Thermal Control Plans

A comprehensive thermal control plan describes the temperature monitoring procedure that the general contractor or concrete sub-contractor must implement when placing concrete in cold or hot weather conditions, as well as that for mass concrete elements. This plan generally includes details on the minimum and maximum allowable temperature values for different structural locations, maximum allowable temperature differential for mass concrete placements, type of equipment, sensors and tools for temperature measurement, frequency and duration of temperature readings, as well as relevant heating or cooling producers.

The in-situ concrete temperature measurements can also be used to estimate the strength of concrete using the maturity method (as per ASTM C1074) in real-time. The possibility of obtaining field strength of concrete (without relying on delayed lab test results), makes concrete temperature measurement even more important particularly in structural concrete elements. In addition to temperature measurement that is an essential part of every thermal control plan, some contractors have been leveraging the maturity method to optimize their project schedules and prevent delays in critical construction operations such as stripping forms, shoring and re-shoring removal, pulling post-tension cables, and opening traffic on concrete pavement. In addition, the simultaneous monitoring of concrete temperature and strength provides opportunities for the optimization of heating and cooling costs, as well as allowing for higher temperature differentials.

What Are the Different Types of Concrete Temperature Sensors and Maturity Meters?

When it comes to the choice of concrete temperature or maturity measurement sensors and equipment, contractor have many options to select based on the cost, accuracy, and ease of use, and of course how all these considerations would fit their project needs and budget. The measurement systems available in the market are categorized as follows:

- Thermocouples

- Wired Temperature and Maturity Loggers

- Wired Concrete Strength Sensors with External Wireless Transmitter

- Fully Embedded Wireless Concrete Strength Sensors

Each of these temperature/maturity monitoring systems has its own advantages and disadvantages, and it is important for contractors to review these before developing their thermal control plans to maximize their return on investment (ROI). It should also be noted that infrared laser-based temperature measurement tools are not recommended for monitoring concrete curing and hardening, as they cannot capture internal concrete temperature.

What Are Concrete Thermocouples and Are They Accurate?

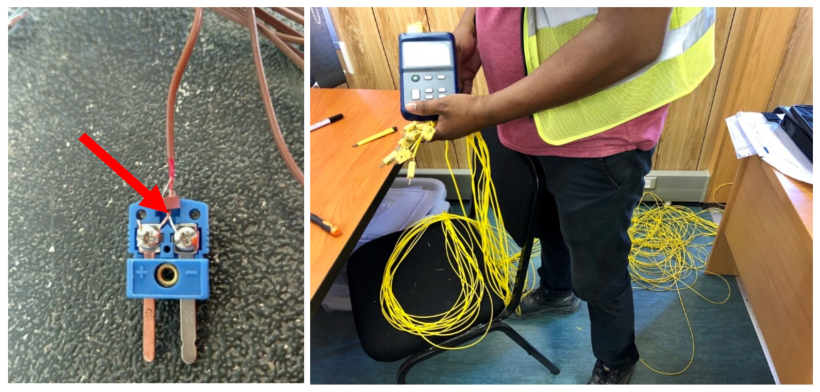

A concrete thermocouple consists of two wires of different metals connected twisted together at one end to form an electrical junction. There is a temperature-dependent voltage that is produced by the thermocouple due to its thermoelectric properties. This voltage is measured by external equipment and is then used to estimate the concrete temperature. The base metal thermocouple types J and K are the most commonly used types of thermocouples in the concrete industry, as they are relatively inexpensive (about $1/ft) and offer a wide range of temperature measurement.

Concrete thermocouple wires are purchased in a bundle which is then cut into custom lengths based on the distance between the location of the temperature measurement and where the measurement equipment is placed. At one end, the two thermocouple metal wires need to be twisted together and at the other end, the two wires are connected to a plug. The wires need to be labeled for identification and stay connected to the external device at all times until the measurement duration is complete. The individual measurements are typically displayed on this unit. Once the measurements are completed, the unit can be connected to a computer to download and analyze the data. Recently, wireless devices have been introduced that send thermocouple measurements to the cloud or smartphone.

Although thermocouples are relatively inexpensive, they have several disadvantages that make them not suitable for use in most concrete thermal control plans. Most importantly, the measurement accuracy of thermocouples is low. Type J and K thermocouples have a standard error limit of at least 2.2°C (about 4°F) for typical concrete temperature ranges. This error is more than two times higher than the minimum measurement accuracy required in most concrete temperature measurement specifications (e.g. ASTM C1064 requires an accuracy of 0.5°C or 1.0°F for fresh concrete temperature measurement). Moreover, it is very time consuming to cut the wires, attach them to the plug, and install the setup in the field. Thin thermocouple wires are also very prone to cuts and damage, and thus measurement errors as they are typically not designed for harsh construction environments. In addition, the wires coming out of concrete and the external unit need to be protected throughout the entire temperature measurement period.

Wired Loggers for Concrete Temperature and Maturity Monitoring

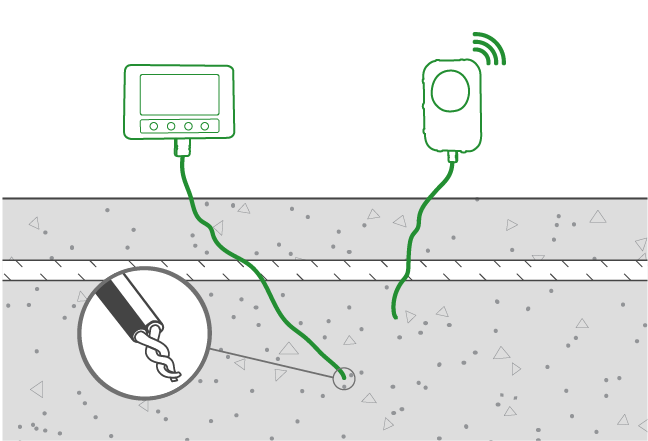

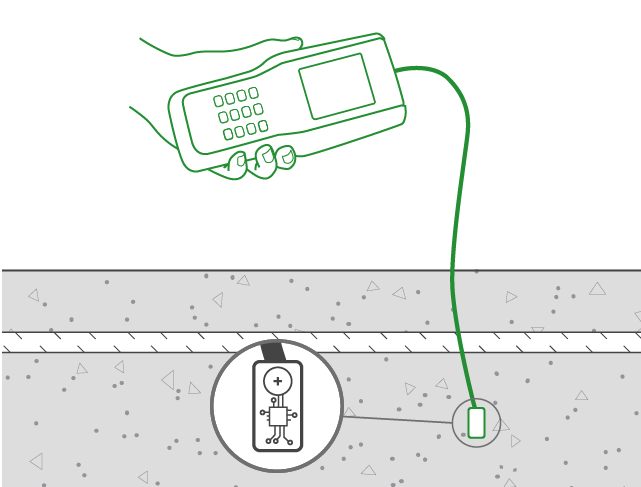

To address some of the deficiencies in thermocouple-based systems, wired temperature and maturity loggers were developed. These loggers and meters have an electronic circuit board that contains a coin-size battery with an onboard thermistor (typically an NTC type sensor) for temperature measurement. The measurements are recorded and stored on this circuit board at pre-defined intervals. The whole circuit board is completely sealed with a connector wire coming out to download the measurements using an external device as needed unlike the thermocouple-based sensors that need to be always connected to an external data recording equipment. For the installation of these systems in concrete elements, the logger (or the sealed circuit board) is placed at the location where the temperature and maturity measurements need to be made. The connector wires are then dragged out of the structural element. After concrete pouring, users can connect their hand-held unit to the end of the wires to download the recorded temperature values.

Learn More About Concrete Maturity

The wires used for these types of temperature/maturity loggers are more rugged compared to thermocouples, which makes them less prone to damage on the jobsite. The external unit is also not exposed to potential damage in a construction environment, as it is used only when downloading the data. External devices can offer various types of data analysis in the field. However, for full analysis and report generation, the data needs to be downloaded later on to a computer.

These types of temperature and maturity loggers don’t have an electrical switch and are always turned on. So, their shelf life is limited. In addition, the industrial-grade connector cable makes these sensors bulky and difficult to install, especially when long wires are used for large structural elements. Similar to thermocouples, the ends of the wires need to be labeled for identification after pouring and have to be protected against potential cuts or other damage to the jobsite. Moreover, finding the cable lead during the first few days after pouring could be challenging as there are many construction tools, materials and components being moved and displaced on the jobsite potentially covering the cable lead.

Wired Concrete Strength Sensors with External Wireless Transmitter

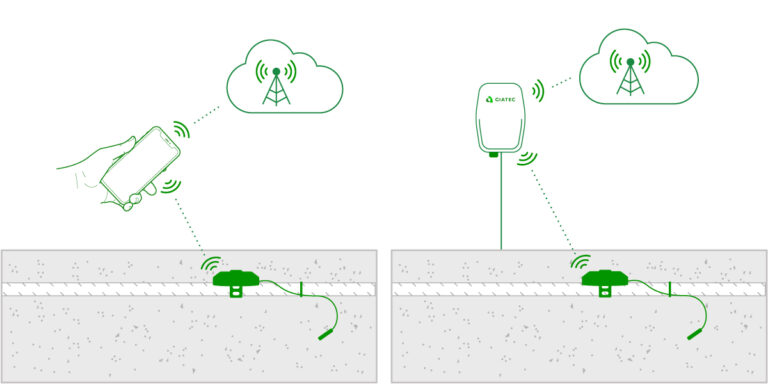

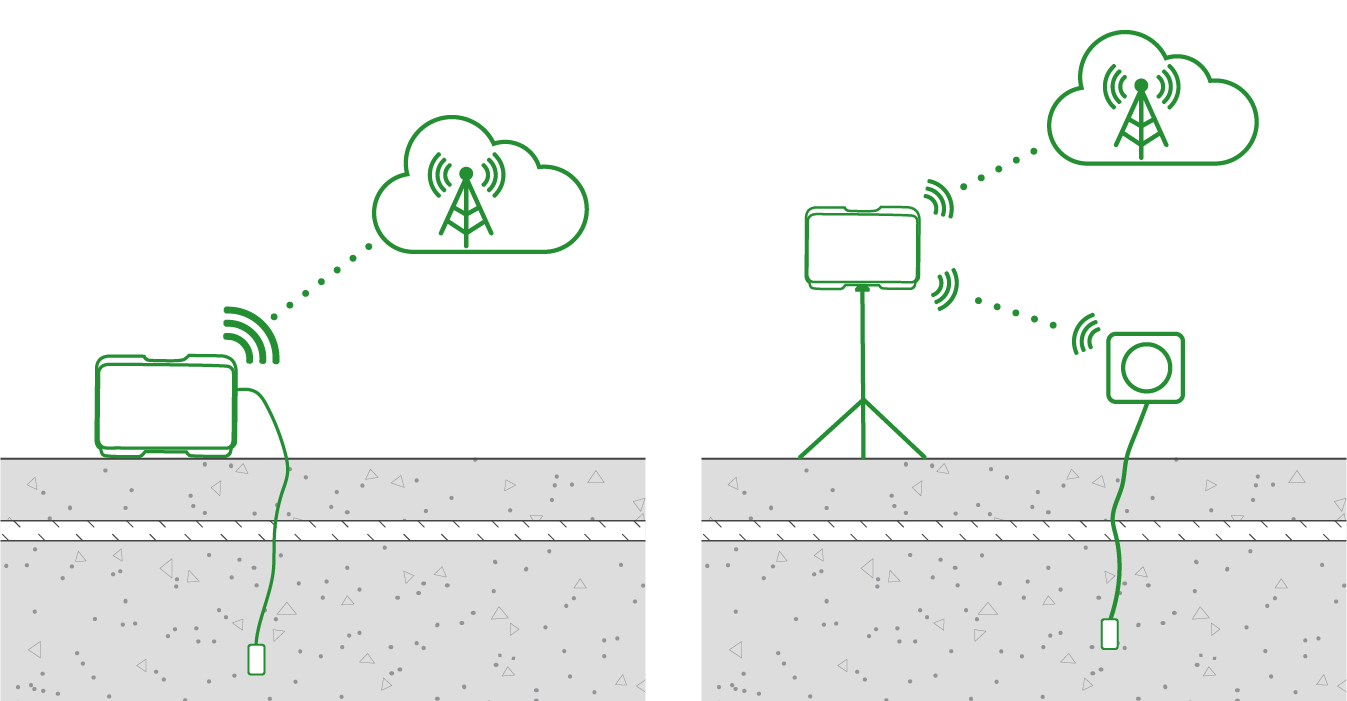

Whether using thermocouples or wired loggers for concrete temperature monitoring, the hassle of connecting an external device and the need to visit the jobsite to collect the data and later downloading it to a computer have prevented these types of sensors from wide industry adoption. With electronic advancements, wireless data transmitters were developed to address the above challenges. These external units are connected to the end of the wires coming out of concrete to store and transfer the temperature measurements over a wireless network either:

- To a computer connected to internet,

- To a local wireless hub or gateway that then transfers data to cloud, or

- Directly to cloud through networks such as LTE or Sigfox.

A great advantage of these wireless systems is that data analysis can be done automatically on the cloud to generate custom alerts and notifications for project managers and superintendents, even when they are not on the jobsite. However, the wire connection to the external unit is still prone to cuts, and the wireless unit located close to the concrete placement can be damaged in a harsh construction environment. Moreover, a complex system comprising wires, external transmitters, and a local hub can be challenging to install and configure as it has several different components. In addition, in remote jobsites where cell network connection is not available or if any of their components are damaged, these systems may not function properly.

Fully Embedded Wireless Concrete Strength Sensors

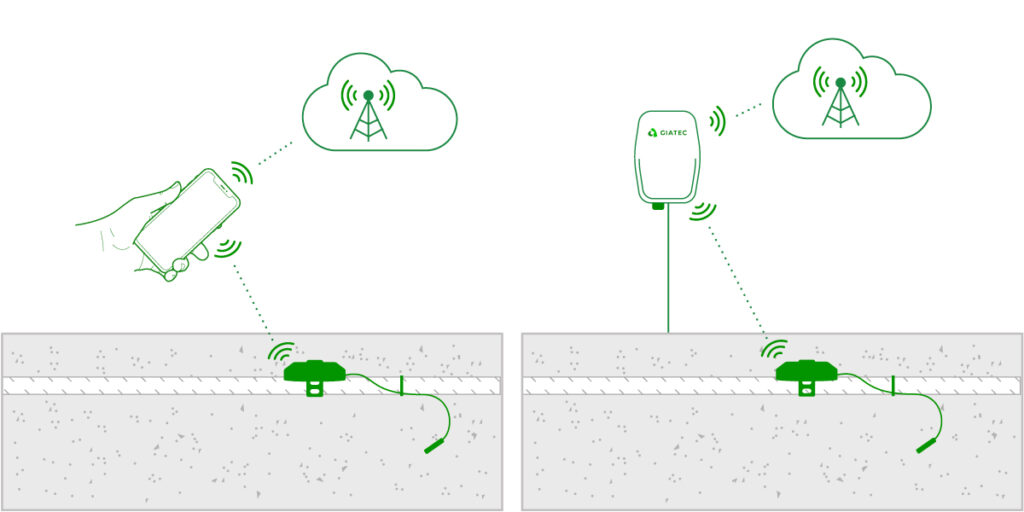

With the advancements in electronics and wireless technologies, it has been possible to design self-contained wireless concrete sensors and loggers that are fully embedded in the concrete. The temperature measurements are stored on the sensor. The recorded data can then be downloaded from the fully embedded sensor through various wireless communication protocols such as LoRa, Zigbee, or Wi-Fi. In the case of wireless systems, a smartphone or tablet can be used to connect wirelessly to the sensor to download the data and analyze it in real-time for maturity and strength estimation using mobile apps. The data is also transmitted to the cloud through the mobile device connection to the cell network. Alternatively, the sensor data can be downloaded automatically using a wireless local hub for transmission to the cloud without the need to visit the jobsite. For the other wireless protocols, the external hub must be used to download and transmit the data to the cloud as mobile devices do not support them.

The main advantage of fully embedded wireless concrete sensors is that, unlike wired systems, they are not prone to potential damage to the construction jobsite after pouring. The data is securely held on the sensor inside the concrete and can be downloaded with confidence at any time. Moreover, the installation and data collection are relatively simpler and faster as there are no wires to be dragged out of concrete, or in the case of wireless systems, no external units that need to be maintained. The overall cost of measurement could therefore be lower than wired sensors. However, due to the sophisticated electronics, the initial purchase cost of these embedded sensors is higher than that of the wired sensors/loggers. It should be noted that the wireless signal from these sensors can only go through a couple of inches of concrete. So, for deeper locations, a temperature measurement cable is used while the wireless sensor’s transmitter is placed inside the concrete typically on the rebar below the concrete surface.

Move Data Center Projects Faster

Types of Commercial Concrete Temperature Sensors and Maturity Meters

A survey of the market shows that there are several options for purchasing a concrete temperature/maturity sensor for monitoring the concrete curing and hardening in your concrete project. This gives contractors a wide range of options for selecting a concrete sensor for their construction project based on the cost, accuracy, and ease of use. Here’s a concrete sensors comparison of commercially available sensors, temperature loggers, and maturity meters in alphabetical order:

Command Center

Command Center was developed by Transtec Group Inc. for concrete temperature and maturity monitoring. The Command Center wired loggers are embedded in concrete. The wire lead can then be connected to a hand-held device to download the data or attached to a wireless transmitter to send the data wirelessly to a mobile device on the jobsite.

Concremote

Doka offers Concremote sensors for concrete temperature and maturity monitoring. Concremote units come in different formats. One of the options is to place the Concremote sensor on the surface of concrete. Data is recorded and transmitted directly to the cloud through a cell network. The other option is to embed wired Concremote sensors inside the concrete and attach a wireless transmitter to the end of the wire for wireless data transmission.

Concrete Sensors

Developed by Structural Health Systems Inc., Concrete Sensors is a fully embedded sacrificial sensor that records temperature and humidity of concrete. The data can be retrieved and analyzed at any time using Concrete Sensors’s mobile application wirelessly. Concrete Sensors also offers another version of their sensor that directly connects to a local gateway for data transmission to the cloud. Concrete Sensors was recently acquired by Hilti.

Con-Cure NEX

Similar to Command Center, the Con-Cure’s wired maturity loggers are embedded in the concrete. The wire lead that comes out of concrete can be connected either to a hand-held device to download the data recorded on the Con-Cure’s maturity sensors, or to a wireless node that then transmits data to the cloud through cell network or save it on an SD card. Con-Cure offers sacrificial and reusable sensors.

Converge

Converge has developed various solutions for concrete temperature and maturity measurement. Their original product (Converge Mesh) included wired sensors connected to wireless nodes that wirelessly send data to a local hub for transmission to the cloud. Converge’s recent sensor called Signal is a wireless sensor that is fully embedded in concrete. Recorded data is wirelessly sent to either a mobile device or a local hub and then to the cloud through a cell network.

Flex Logger

Exact Technology provides concrete monitoring systems using external temperature (and optional humidity) probes embedded in concrete. These wired probes connect to a logger placed outside the concrete, which transmits data wirelessly—depending on the setup—to the cloud or a mobile device. Data is analyzed online for maturity and strength.

The Flex Logger is a compact, battery-powered device that connects to up to four external probes. It stores data internally and transmits it wirelessly, without the need for external power, relays, or hubs.

HardTrack

Wake Inc. offers the RFID-based HardTrack sensor. The HardTrack sensor comes in different formats. The temperature measurement cable is connected to an RFID reader. The RFID tag can either be embedded in concrete or placed outside to be reused. Users can use an RFID reader to retrieve the recorded data or install a local hub to wirelessly download the data for transmission to the cloud.

HOBO

HOBO developed by ONSET is one of many commercially available thermocouple data loggers. Multiple thermocouple wires can be connected to a HOBO box that is installed outside the concrete. HOBO offers a regular logger that records the data for processing later on a computer, as well as a wireless logger that can record and send the temperature data wirelessly to a mobile device. Users need to calculate the concrete maturity and strength themselves based on the temperature results.

InSite

InSite by RPX Technologies is a wireless concrete temperature and strength monitoring system. Its rugged, self-activating loggers detect fresh concrete and begin recording automatically using triple-redundant thermistors. Data is sent via remotes or cellular modules to the cloud for real-time access and alerts, supporting maturity-based strength tracking and compliance.

LumiCon

Brickeye offers LumiCon concrete sensors. Lumicon can measure temperature at multiple pre-made locations across its cable. The cable end that comes out of the concrete is connected to a wireless transmitter, which sends data to a local hub and then to the cloud. The data analysis and concrete maturity calculations are performed on the cloud. Data is also accessible using LumiCon’s mobile app.

Maturix

As of 2025, Saint-Gobain offers Maturix sensors for concrete temperature and maturity monitoring. Maturix uses thermocouple sensors. One end of the thermocouple wires is embedded in concrete and the other end needs to be connected to a node. Each wire needs to have a separate node. The nodes record the concrete temperature data and send it wirelessly to the cloud (either directly if Sigfox network is available or otherwise through a local gateway).

REBEL

REBEL by WaveLogix is a fully embedded sensor that monitors concrete strength and temperature using piezoelectric resonance. It provides direct, calibration-free strength data and complies with AASHTO T-412-24. The system includes a separate Sentry logger for data transmission, which adds flexibility but may require additional handling during setup.

SmartRock®

SmartRock is Giatec’s fully embedded wireless sensor for monitoring concrete temperature and strength using the ASTM C1074 maturity method. Installed directly on rebar with no exposed wires, it begins recording as soon as concrete is poured. Data is transmitted via Bluetooth® to the SmartRock mobile app or SmartHub™, with full access through the Giatec 360™ cloud dashboard. The sensor features dual-temperature monitoring, long battery life, and a rugged, waterproof design for reliable performance in tough jobsite conditions. The SmartRock sensor helps streamline decision-making, reduce reliance on break tests, and keep construction on schedule.

SmartRock Pro

SmartRock Pro is Giatec’s most advanced concrete sensor, delivering real-time temperature and strength data without the need for external loggers or manual calibration. Utilizing patent-pending Concrete Electro-Mechanical Microstructural Analysis (CEMMA) technology, it directly measures in-place strength with lab-grade accuracy. It is the world’s first fully embedded, wireless, and self-calibrating sensor, adapting to changes in mix design and jobsite conditions automatically. Designed for straightforward installation and effortless data access through the SmartRock app or Giatec 360 dashboard, SmartRock Pro provides a more streamlined path to reliable, actionable insights in the field.

WEDGE

WEDGE by United Rentals is a wireless environmental monitoring system used on construction sites to track temperature and humidity, including within curing concrete. Data is transmitted to a cloud dashboard with real-time alerts via SMS or email.

vOrb

The Concrete QC software company, Quadrel, offers vOrb sensors in different formats. The vOrb sensors which use wifi communication protocol are embedded in the concrete. The data needs to be retrieved via a local hub before it is transmitted to the cloud. Quadrel offers another version of vOrb sensors for monitoring the temperature and maturity of concrete cylinders.

Concrete Sensors Comparison: Which Concrete Sensor Should You Use in Your Project?

When it comes to selecting a concrete temperature sensor or maturity logger for your next thermal control plan or field strength monitoring, there are many options that you can consider based on the sensor cost, its accuracy, and ease of use. Each of these considerations can affect the overall cost and time needed to setup, collect, analyze and report the temperature, maturity and strength data, and ultimately impacts the ROI related to monitoring the curing and hardening of your concrete placements.

Here is a summary of the commercially available concrete temperature/maturity sensors categorized based on their type:

| Thermocouple | Wired Loggers | Wired Sensors with External Wireless Nodes or Gateways | Fully Embedded Wireless Sensors | |

| Command Center by Transtec Group Inc. |

• | • | ||

| Concremote by Doka |

• | |||

| Concrete Sensors by Hilti |

• | |||

| Con-Cure Nex |

• | • | ||

| Converge Signal |

• | • | ||

| Flex Logger by Exact Technology |

• | |||

| HardTrack by Wake Inc. |

• | • | ||

| HOBO By ONSET |

• | |||

| InSite by RPX Construction |

• | • | ||

| LumiCon by AOMS Technologies |

• | |||

| Maturix by Saint-Gobain |

• | • | ||

| REBEL by WaveLogix |

• (Partial) |

• | ||

| SmartRock by Giatec |

• | |||

| SmartRock Pro by Giatec |

• | |||

| vOrb by Quadrel |

• | |||

| WEDGE by United Rentals |

• (Via Adapters) |

• (Partial) |

Conclusion

Selecting the right concrete sensor comes down to understanding your project requirements and the conditions you’re working with. From traditional wired systems to modern wireless solutions, each option brings different advantages in terms of accuracy, accessibility, and ease of use.

Accurate monitoring helps contractors maintain control over curing conditions, make timely decisions, and keep critical tasks on schedule. It also supports better planning, reduces unnecessary delays, and improves overall efficiency on the jobsite.

By aligning your sensor choice with your thermal control strategy, you can improve the reliability of your concrete operations and move forward with greater confidence in the data you’re collecting.

Frequently Asked Questions

How is data from concrete sensors accessed and analyzed?

Depending on the sensor type, data can be retrieved manually via a wired connection, downloaded wirelessly, or transmitted automatically to a cloud dashboard through hubs or mobile devices. Most advanced systems support real-time alerts and analytics.

Are there standards that govern the use of concrete sensors?

Yes. ASTM C1074 outlines procedures for estimating concrete strength using the maturity method, and ASTM C1064 specifies accuracy requirements for measuring fresh concrete temperature.

What are the benefits of using self-calibrating sensors like SmartRock Pro?

Self-calibrating sensors like SmartRock Pro eliminate the need for developing mix-specific maturity curves, which can be time-consuming and prone to variability. Instead, they use proprietary technology to analyze the concrete’s internal properties in real time, adapting to on-site conditions such as water additions or admixture changes. This not only streamlines deployment but also improves data reliability across multiple pours and mix designs. With SmartRock Pro, you can make strength monitoring more consistent, scalable, and accessible for project teams operating under tight schedules.

Can concrete sensors help reduce construction costs?

Absolutely! Real-time strength and temperature data help optimize curing practices, reduce unnecessary heating or cooling, accelerate construction timelines, and avoid costly delays from relying solely on break tests.

Note: All company, product/service names, and brands used in this article are property of their respective owners. This article is intended to be used for informational purposes only.

*Editor’s Note: This post was originally published in April 2020 and has been updated for accuracy and comprehensiveness as of June 2025.