Mass concrete temperature differentials are one of the leading causes of thermal cracking in large concrete pours. When the internal core heats up during hydration while surface temperatures cool, tensile stresses develop that concrete cannot withstand. Without proper monitoring, these stresses result in early-age cracking, reduced durability, and costly repairs.

Move Data Center Projects Faster

Closely monitoring concrete temperatures is critical for ensuring proper strength development of concrete structures and concrete sustainability regardless of their application or size. However, when it comes to mass concrete structures, we need to consider temperature differentials due to the risk of a large difference between the relatively hot internal temperature and the cool surface temperature. If a too-large temperature differential occurs, the surface of mass concrete will start cracking. This is detrimental to its durability and the length of its service life.

In this blog, let’s take a look at why managing mass concrete temperature differentials is important for preventing thermal cracking and ensuring long-term structural durability.

What Is Mass Concrete?

Mass concrete is not defined by any specific measurements. According to the American Concrete Institute (ACI), mass concrete is “any volume of concrete with dimensions large enough to require that measures be taken to cope with the generation of heat from hydration of the cement and attendant volume change to minimize cracking.” Some examples of mass concrete include dams, large bridge piers and columns, mat slabs and foundations.

From a temperature-control perspective, mass concrete is defined not only by size, but by its ability to retain heat. Once concrete elements exceed approximately 3 feet (0.9 m) in thickness, heat generated from hydration becomes trapped, creating internal temperature gradients that do not occur in conventional structural concrete.

Learn how to elevate your mass concrete projects here!

It’s important to note that smaller structures may also be categorized as mass concrete depending on several factors. This includes: type and quantity of cement, volume to surface ratio of the concrete, weather conditions, concrete placing temperatures, degree of restraints to volume changes, and the effect of thermal cracking on function, durability and appearance.

Why Is It Important to Monitor Mass Concrete Temperature?

In order to ensure that mass concrete properly cures to reach adequate strength, it must be poured when the ambient temperature is between 50-60 °F (10-16 °C). If the temperature is too low, the chemical reactions that strengthen the concrete slow down significantly. At a certain point, it will come to a complete stop. If the temperature is too high, it will cause the concrete to have high early strength development. However, it will consequently gain less strength in the later stages. This results in lower overall durability of the structure.

How Do Temperature Differentials Affect Mass Concrete?

As concrete hydrates and hardens, it generates heat. When constructing mass concrete structures, significant tensile stresses and strains are likely to develop. This is due to the difference between the structure’s core temperature and surface temperature (which is known as the temperature differential). These stresses occur because the volume of the warmer concrete expands while the cooler concrete contracts.

The likelihood of thermal cracking increases as the inner core of the mass concrete continues to heat (hydration) while the outer surface of the concrete cools (heat dissipation). This is exacerbated by extreme cold weather, which quickly cools the outer surface of the concrete, but does not reach the inner core.

Learn more about thermal cracking here!

According to ACI 301-16: Specifications for Structural Concrete, the maximum concrete temperature differential should not exceed 35 °F (19 °C) during curing. In most situations, this approach is very conservative. In other cases, it can be an overestimation of the allowable temperature differential.

Without monitoring temperature differentials in mass concrete, contractors and project managers could run into serious problems. This can include cracking, reduced service life, project delays and noncompliance. These problems can make it hard to have a sustainable concrete construction.

Allowable temperature differentials can vary depending on structure type, restraint conditions, and service requirements. Crack-sensitive or watertight structures often require more conservative limits than general mass concrete applications.

Mass Concrete Temperature vs. Temperature Differential

A common misconception in quality control is focusing only on peak concrete temperature. In reality, thermal cracking risk is driven by temperature differential, not absolute temperature.

A temperature differential is defined as the difference between the hottest point in the concrete (typically the core) and the coolest point (typically near the surface).

Thermal stress increases as this gradient increases. Even when both core and surface temperatures are moderate, a large differential can generate high tensile stresses at the surface. To calculate temperature differential, use this equation:

Temperature Differential = Core Temperature – Surface Temperature

For example:

- Core at 160°F (71°C) and surface at 140°F (60°C) results in a 20°F (11°C) differential, which is often manageable.

- Core at 140°F (60°C) and surface at 100°F (38°C) results in a 40°F (22°C) differential, significantly increasing cracking risk.

This is why monitoring both locations simultaneously is essential. The differential typically peaks between 24 and 48 hours after placement, which is the most critical window for intervention. This early-age period is when mass concrete is most vulnerable to thermal cracking and requires the closest temperature monitoring.

Move Data Center Projects Faster

What’s the Best Way to Monitor Temperature Differentials?

On construction sites, temperature differentials are normally measured using thermocouples or data loggers. Unfortunately, using these tools to collect data and subsequently analyzing the data on a computer becomes quite time-consuming. This can negatively impact a project’s schedule.

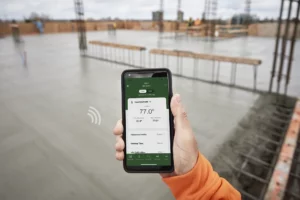

Fortunately, contractors and engineers can take advantage of advanced technology that uses the maturity method to monitor concrete temperatures. One such technology is Giatec’s SmartRock®, which has now been re-engineered with innovative dual-temperature capabilities. This trusted wireless sensor, used on over 6,200 sites worldwide, is installed on the rebar before a mass concrete pour. It enables the measurement of concrete temperatures in two locations simultaneously. These locations typically represent the hottest point at the core and the coolest point near the surface, which together define the maximum temperature differential.

These easy-to-install sensors offer precise real-time temperature readings for mass concrete pours at the surface and center of the slab, which are immediately sent to the user’s mobile device.

For greater control over the monitoring and analysis of mass concrete element temperatures, project owners and contractors can implement SmartRock Long Range. It is a remote monitoring system across large job sites that allows users to access SmartRock data any time, anywhere (even off-site), up to 1000 ft (300m).

Read more about SmartHub here!

Why Are Temperature Differentials in Mass Concrete So Important in Winter?

During cold weather, mass concrete temperature differentials become more pronounced because surface cooling accelerates while the internal core remains warm. In ACI 306: Guide to Cold Weather Concreting, cold weather concreting is defined as “a period when for more than three successive days the average daily air temperature drops below 40°F (5°C) and stays below 50°F (10°C) for more than one-half of any 24-hour period.”

Along with slowing down the curing process, cold weather also causes the water in concrete to freeze and expand. This causes cracking and weakening of the concrete, rendering it useless in some cases. However, it can still be successfully poured and placed in winter as long as the right precautions are taken to heat it properly.

Cold-Weather Concreting Tips

Here are a few tips on how to control the temperature of your concrete in cold weather:

- Keep the concrete in a dry and heated area until it’s ready to use.

- Install internal electric heating: This requires using embedded coils and insulated electrical resistors.

- Optimize your concrete mix: Using low-heat cement, aggregate substitutes (such as fly ash, limestone, or slag), and a low water-to-cementitious materials ratio are all good ways to optimize your concrete mix for heat retention in cold weather.

- Use insulation: Layering helps maintain the heat generated from the concrete. Insulation methods like heating blankets or forms allow you to control temperature differentials between the core and the surface of your slab.

- Cool your mass concrete pour before placement: This can be done using chilled water, chipped or shaved ice, or liquid nitrogen.

- Cool the concrete after placement: Use embedded non-corrosive cooling pipes prior to concrete placement. This removes heat by circulating cool water from a nearby source.

- Remove standing water: Bleed water needs to evaporate or be removed by a squeegee or vacuum.

For more tips on cold weather concreting, see our blog on 7 common mistakes to avoid in cold weather concreting!

Hot Weather Concreting Tips

Generally, a concrete temperature is limited to 70°C (160°F) during hydration. If the temperature of the concrete during hydration is too high, it causes the concrete to have high early strength development. Consequently, it will gain less strength in the later stage, resulting in lower durability of the structure overall. Furthermore, such temperatures can interfere with the formation of ettringite in the initial stage. Subsequently, its formation in the later stages is promoted. This causes an expansive reaction and subsequent cracking.

Additionally, high temperature issues are of concern–especially in mass concrete pours. The core temperature can be very high due to the mass effect, while the surface temperature is lower. This causes a temperature gradient between the surface and the core. If this differential in temperature is too large, it will cause thermal cracking. This means temperature differentials are a concern in both hot and cold weather conditions, and not just during winter placement.

The first step to ensuring adequate strength gain of mass concrete in cold weather is to gather accurate data. With SmartRock’s dual-temperature functionality, users are equipped with the data they need to inform them when their mass concrete reaches critical temperatures and how much it needs to be heated.

Conclusion

A well-planned mass concrete temperature-monitoring strategy focused on temperature differentials is one of the most effective ways to reduce cracking risk and improve construction quality.

Ultimately, managing mass concrete temperature is less about chasing a single maximum temperature and more about controlling how heat moves through the structure. By focusing on temperature differentials, construction teams can identify cracking risk earlier and take corrective action before damage occurs.

**Editor’s Note: This post was originally published on November 2020 and has been updated for accuracy and comprehensiveness as of January 2026.