In recent years, the development of large concrete structures has become increasingly common due to its many structural benefits. Concrete presents a number of characteristics that improve the sustainability performance of a structure. It offers durability, increased structural capacity, resistance to fire and flooding, and optimal sound isolation.

Move Data Center Projects Faster

However, with these benefits comes a critical challenge: temperature recording concrete during curing, particularly in mass concrete applications. Without accurate temperature data, projects risk thermal cracking, reduced durability, and costly repairs.

This blog explores the fundamentals of temperature recording concrete, why monitoring mass concrete temperature matters, and compares traditional thermocouples with modern sensor-based solutions so project teams can make informed decisions for quality control and compliance.

What is a Mass Concrete Element?

Mass concrete is categorized as any volume of concrete with dimensions large enough to require that measures be taken to cope with the generation of heat hydration of the cement and attendant volume changes to minimize cracking. When it comes to large bodies of concrete, one of the most important characteristics is thermal behavior. For mass concrete projects such as buildings, dams, bridges, tunnels, etc., the rate at which the heat is generated is higher than that at which it is released causing the overall temperature to increase over the duration of the curing stage.

Due to the slow release of heat from concrete during this stage, and concrete’s low conductivity, mass concrete can experience gradients in temperature and a portion of heat can become trapped in the center of the mass concrete element, which can cause a slow release of the heat and lead to cracking.

Curious About Determining the Allowable Variation in Concrete Temperature? Learn more here!

What is Mass Concrete Temperature Monitoring?

Mass concrete temperature monitoring is the action of recording and reading the temperature of freshly poured mass concrete elements. This requires a temperature recording sensor (also known as a thermocouple for mass concrete) to be placed near the center of the element. Some temperature recording concrete devices include:

- Embedded thermocouples

- Wireless concrete temperature sensors

These devices are typically placed at varying depths to capture both core and surface temperatures. Continuous monitoring allows teams to track temperature rise, cooling rates, and critical temperature differentials.

Why Is It Important to Monitor Mass Concrete Temperature?

In order to ensure the quality and durability of larger projects, it is important to monitor and record the temperature of your concrete. It is also necessary to control the mix temperature, ambient temperature, and differential temperature in mass concrete elements. Temperature differences can cause stress that leads to thermal cracks and loss of structural integrity, thus shortening the life and decreasing the strength of the mass concrete element. If the temperature goes below a certain number, the hydration of water can slow or stop meaning the concrete won’t set properly and won’t achieve optimal strength. When concrete temperatures are properly monitored, appropriate adjustments are able to be made when needed. Many specifications aim to keep the core-to-surface temperature differential within approximately 35°F (19°C) to reduce this risk.

Heat generation depends on many factors, such as the compound composition, the initial temperature of the concrete, the ambient temperature, the shape of the mass concrete element, the volume-to-surface ratio, as well as other surrounding conditions. Generally, the higher the cement content, the more heat will be produced.

When temperature recording concrete is done correctly, contractors can make timely adjustments to curing methods and cooling strategies. There are a number of ways in which you can regulate the temperature of mass concrete elements during a project, starting with an initial cooling of the concrete mixture. This can be done with the use of chilled water, ice, or liquid nitrogen. Temperature regulation can also be made throughout the project by running cool water through cooling pipes installed before the concrete placement. Thus, in order to know when it is appropriate to undertake cooling processes, temperatures must be monitored in real-time with a thermocouple for concrete.

Read More About Monitoring Concrete Temperature in Cold Weather Here!

Move Data Center Projects Faster

The Temperature Monitoring Process

The initial process for heat monitoring of concrete mixtures is based on predictions made by taking into account the design of the concrete mix, the shape of the project, the ambient temperature, and more. Once the concrete is in place, sensors for temperature recording concrete and thermocouples are used to report changing temperatures.

There are a few different devices and sensors that allow concrete temperature measurement currently on the market. Some of them are Con-Cure, Wake HardTrack, Command Maturity Central, Doka Concremote, and SmartRock®. Each offers its temperature analysis through the different stages of the project so you can gather accurate data and make necessary adjustments.Thermocouples vs. Sensors for Temperature Recording Concrete

Thermocouples vs. Sensors for Temperature Recording Concrete

Thermocouples are a time-tested solution for temperature recording concrete. They offer:

- Lower initial cost per measurement point

- Reliable temperature readings when installed correctly

However, thermocouples require:

- Manual data collection

- Frequent site visits

- Careful documentation to avoid gaps or errors

They are best suited for smaller pours or projects with experienced QC teams and limited monitoring needs.

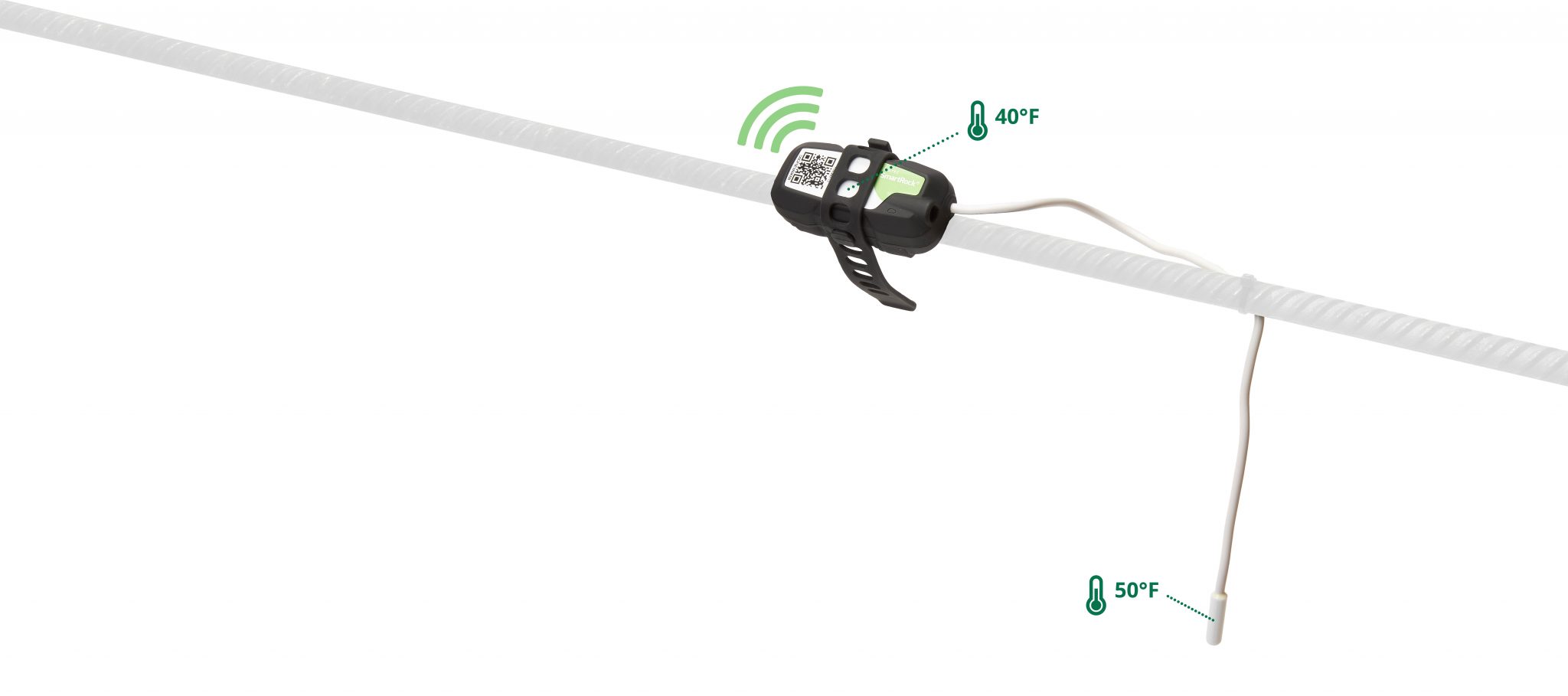

SmartRock Wireless Concrete Temperature Sensor

The SmartRock sensor allows for high-accuracy data collection and easy report sharing through the Android and iOS app. Like other temperature measurement and monitoring devices, the sensors are placed on the rebar before the concrete pour and can be used from the moment the concrete is poured to the completion of the project. This type of sensor or thermocouple for mass concrete measures the temperature development at regular intervals to deliver high-accuracy data and enable contractors to make appropriate decisions regarding temperature control during the curing stages of the project. This ensures the best possible results for the project.

Unlike many other sensors on the market, the SmartRock is completely wireless and can be accessed from a smartphone device or tablet. The wireless capabilities allow for more freedom and security by removing the risk of tripping over wires or protruding devices. Contractors also benefit from less destructive testing methods. All of the hardware used as well as the concrete stays intact throughout the data gathering process, and there is no need for last-minute repairs or adjustments. There are several additional features as well, such as a database of mix calibrations and easy software upgrades.

The advances in concrete temperature monitoring technology are helping contractors and the construction industry move towards more sustainable, durable, and safe environments.

Conclusion

Temperature recording of concrete is fundamental to successful mass concrete construction. Whether using traditional thermocouples or modern wireless sensors, the objective remains the same: control heat, prevent cracking, and ensure long-term durability.

Thermocouples remain a viable option for smaller or budget-sensitive projects. However, automated sensor-based monitoring offers significant advantages in labor reduction, real-time alerts, and documentation quality, especially for large or complex pours.

By integrating temperature recording concrete into your thermal control plan from day one, you protect your structure, your schedule, and your bottom line.

Learn how mass concrete monitoring can help your concrete projects.

**Editor’s Note: This post was originally published on July 2017 and has been updated for accuracy and comprehensiveness as of January 2026.