Construction is difficult and complex. As the design and architecture of buildings and infrastructure progresses – the means, methods, and tools used to build the structures are required to advance at a similar rate. This has been a challenge for an industry that has historically been behind the curve when it comes to adoption of change and technology.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

In response, technology companies such as Giatec Scientific and binni have developed solutions to push the construction industry forward and help contractors meet these challenges. These tools are developed to help builders become more efficient. Furthermore, it allows them to make more informed decisions by capturing a greater amount of data, providing them with the abilities to put this information to work.

Equally as important as these solutions, is a philosophy that has been embraced by both companies; opening and integrating platforms such that users can easily interact with data from multiple systems in a variety of ways – “At Giatec, we believe that open API for connecting data management platforms is an essential component in the digitization of the construction industry.” states Aali Alizadeh, Co-Founder, President, and CTO at Giatec. As more technologies are introduced into the industry it becomes more and more critical for contractors to have the ability to consume data in an efficient and productive manner using tools they are most comfortable with. Giatec and binni joined forces to put this philosophy to work with great success at the Northeast Boundary Tunnel project in Washington DC.

The Project: Northeast Boundary Tunnel

The Northeast Boundary Tunnel project (NEBT), contracted to The Lane Construction Corporation (formerly Salini/Impregilo/Healy JV), is the third in a series of tunnels that are part of the DC Clean Rivers Project. The tunnel is 8.2 km (5.1 miles) in length and will have a finished diameter of 7 meters (23 feet). Along the tunnel alignment there are nine sites on surface consisting of drop shafts and adits connecting to the tunnel up to 31 meters (100 feet) below. Thousands of cubic yards of concrete will be poured across these nine sites throughout the duration of the project. A project of this magnitude requires concrete mix designs and placements ranging in complexity, including mass placements necessitating the use of temperature monitoring meters.

To manage the concrete placements, Lane has employed the use of binni Concrete to capture, organize, and distribute the logistical and quality control information associated with each pour. The entire construction team utilizes the platform to collaborate in real time in the planning, execution, and reporting of each placement that occurs on the project. In addition, the owner required the use of temperature monitoring sensors to track the temperature differential of the interior and the exterior of the concrete during curing. For this, Lane chose to use the SmartRock® sensors from Giatec.

While the two systems (SmartRock and binni Concrete) more than met the needs of the contractor as stand-alone systems, there were still additional efficiencies to be had. The contractor was interested in being able to interact with both tools within a single platform. They, like most builders, had a level of comfort using particular systems and were reluctant to juggle multiple software to manage different aspects of a placement. Too often, trying to figure out how to manage this is left to the contractor which decreases efficiency instead of increasing it. Giatec and binni recognized that Lane had a need and made the decision to work together to solve the problem.

The Solution: Integrating Project Software with REST API

To address the issue of inefficiencies related to management of different aspects of a construction project, in this case the concrete placements, with a multitude of technologies, Giatec and binni worked together to integrate their two systems. This provided the user the ability to access the information from both software programs in a single platform. Now, instead of having to access binni Concrete and then having to separately log onto Giatec 360 (the platform used to manage the information received from the SmartRock sensors), the user can simply open binni to visualize and interact with the information provided by both Giatec and binni.

Lane has been taking advantage of this integration at the NEBT for their mass placement pours since late February 2020. The project engineers, who were already monitoring placements in real-time through the binni platform, are now able to also monitor the in-place concrete temperatures in the same window. No longer do they have to spend time switching between platforms.

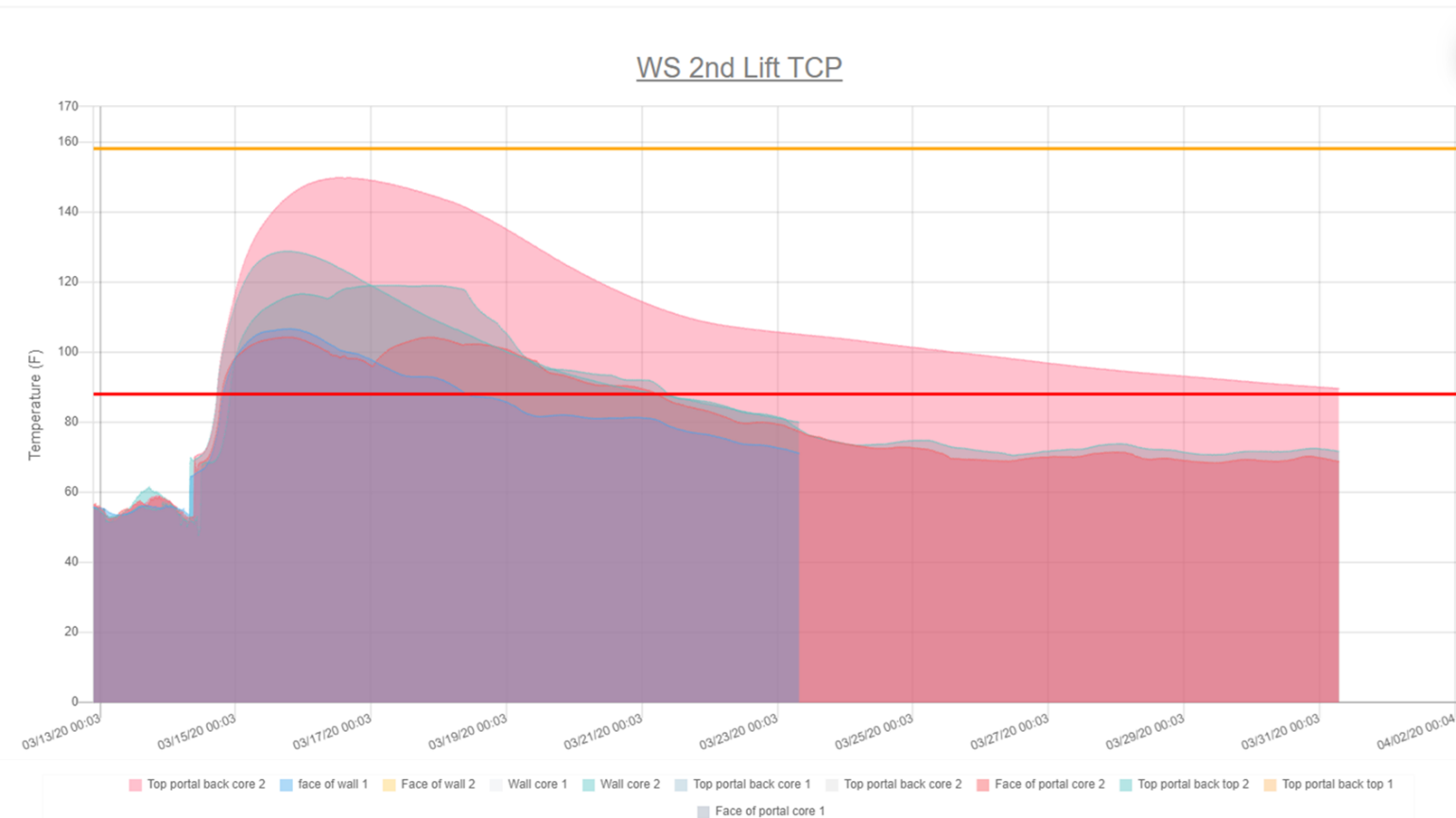

Federico Bonaiuti, Associate Engineer for The Lane Construction Corporation stated “In my opinion, the integration of the graphs produced by Giatec’s temperature monitoring sensors into the binni platform have been saving us a substantial amount of time. Binni is the platform that we use in order to control all aspects of our concrete pours. The fact that we can have the temperature monitoring graphs in the same platform that we use for all aspects of concrete pours is saving us a lot of time since we avoid jumping from one platform to another. In addition, binni has the capacity to live integrate all the sensor temperatures in a unique graph, allowing for us to not have to download the raw data into Excel and manually plot the graph from the sensor data on a daily basis.”

Giatec and binni continue to evaluate synergies between the two companies to determine what else can be done together to help contractors work more efficiently and become more productive. After this initial success, the appetite and will for continued joint innovation has only increased for both companies. Dr. Alizadeh applauded the effort of both teams, “We are happy to see that binni has successfully leveraged the SmartRock API to increase the project management efficiency for our mutual customers. binni’s team was very agile and worked closely with our team at Giatec to build this integration.” Giatec and binni are both in the business of making the life of a contractor easier and know that to accomplish this technology companies must make an effort to integrate platforms and provide the tools for the users to consume the information in whatever manner they are most comfortable with.

About binni

binni, Inc. is transforming how concrete placements are managed by digitizing the planning, tracking and reporting of concrete placements within a single platform. binni helps construction teams increase productivity by simplifying the collection of production and quality information by field teams and streamlining the delivery of reports and submittals.