In a typical construction project, the strength of the concrete is assumed to be the same as the strength of the cylinders cast from that same load of concrete. Cylinders are made in the field, by a technician and cured under standard conditions. The cylinders are not intended to measure the concrete in the structure, but rather as a check on whether the concrete producer batched the correct material.

Big Projects Deserve Better Protection

The problem with this cylinder break tests is that they are based on too many assumptions and fail too often. So, is there a better method for testing concrete in the field? Perhaps a method that analyzes the concrete in the structure itself?

Using the Maturity Method to Estimate Concrete Strength

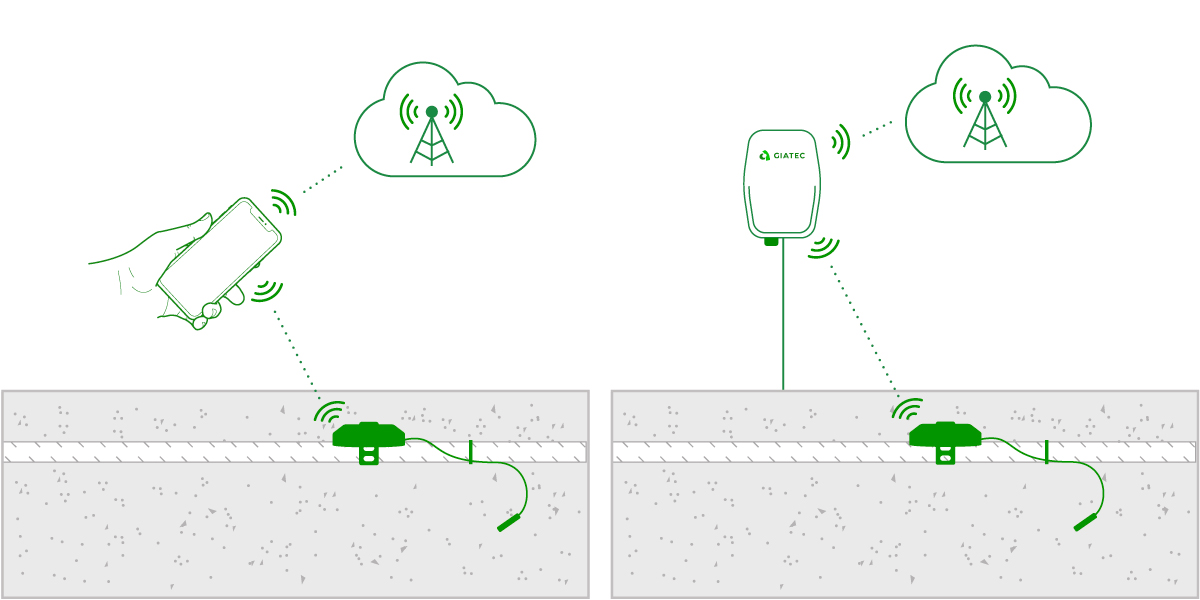

SmartRock® Plus is based on the concrete maturity function, a 65-year-old concept that contractors like and engineers respect. Although not as popular as traditional break testing (not yet, at least), the maturity method is not definitely not new, nor is it inferior to cylinder breaks. In fact, maturity is an ASTM-certified method that monitors concrete properties while eliminating the influence of unskilled technicians or improper curing conditions. Maturity is best at measuring early strength of concrete up to maybe seven days.

So, when could maturity be used for acceptance? It makes the most sense when the strength of the concrete reaches design strength at an early age. This might be an applications with heavily over-designed mixes, where heating is used to accelerate strength, or when chemical accelerators are used to enhance setting time. In any situation where the design strength is achieved in the first few days is an ideal situation for using maturity for acceptance when coupled with the standard density test (ASTM C 138) as the check on whether the concrete producer batched the correct material.

Breaking concrete cylinders (ASTM C 39) has its place as a lab test to measure the potential strength of a concrete mixture, but has failed the industry too many times to be considered a reliable field test. The industry is ready for a change, and SmartRock® Plus built on ASTM C 1074 will be that change for concrete that reaches design strength at early ages.