Properly testing your concrete and logging data is essential to your construction project! There are many methods and tools on the market that allow you to easily gather the important temperature and strength information that you need. Concrete temperature loggers and concrete maturity devices have become increasingly popular over the last decade and there are many options available for your job site. Keep reading to find some of the best options in the market.

Move Data Center Projects Faster

What is Concrete Maturity?

Concrete maturity is an index value that represents the progression of concrete curing. It is based on an equation that takes into account concrete temperature, time, and strength gain. Concrete maturity is an accurate way to determine real-time strength values of curing concrete.

How Does Maturity Relate to Your Concrete Temperature Loggers?

The maturity method is a convenient approach to predict the early age strength gain of concrete, using the principle that the concrete strength is directly related to the hydration temperature history of cementitious paste. The maturity concept for estimating the strength gain of concrete is described in ASTM C1074, Standard Practice for Estimating Concrete Strength by the Maturity Method.

Thermocouples or sensors allow you to implement this method by measuring the temperature of your concrete, and then calculating its strength or maturity via a logger or app.

Learn more about the concrete maturity method here!

Different Types of Concrete Temperature Loggers

There are several different options available on the market when it comes to concrete maturity devices and concrete temperature loggers. Contractors may consider important variables such as cost, accuracy, ease of use, and how all these considerations fit into their project and budget needs.

The main types of maturity devices include wired thermocouples with an external logger, and fully-embedded wireless sensors.

1. Wired Thermocouples With an External Logger

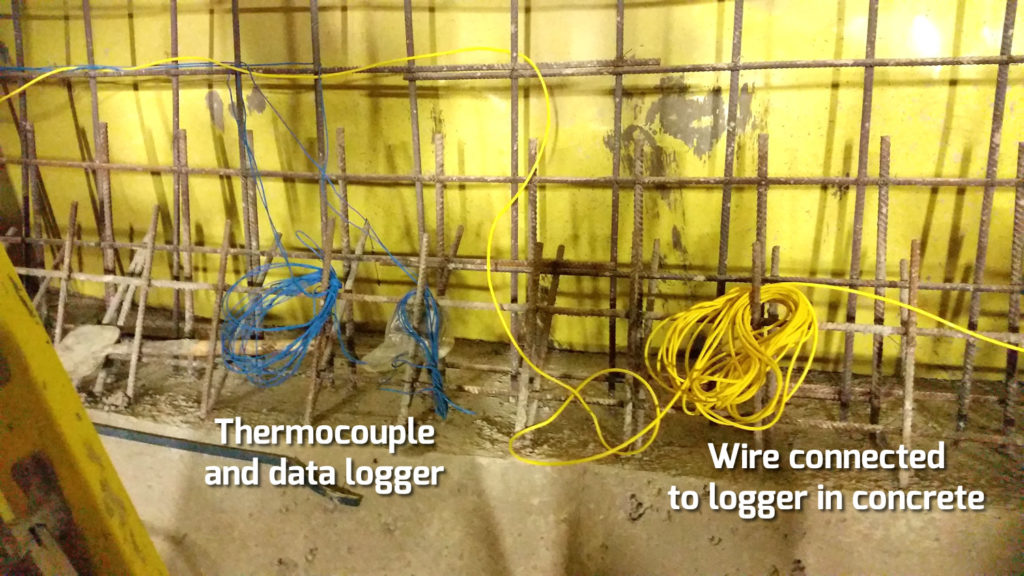

For many decades wired thermocouples with external loggers have been used to monitor concrete temperature and gather data. The end of the thermocouple is placed within the formwork prior to the concrete pour and wired outside the formwork. These systems are usually attached to an external data logger which assists in recording temperature at certain time intervals. In this case, the process of collecting data includes collecting the information on a data medium, uploading it to a computer, exporting it in a CSV or Excel sheet, and manually analyzing the logs. However, recent developments have made it possible to attach a wireless transmitter to send data as well.

Pros

- Simple and relatively inexpensive

Cons

- Labor intensive data collection and analysis process

- Data logger needs to be protected or kept in a secure place for later access

- Device’s wires are inconvenient to have on a construction site (can be easily damaged, during, or after the pour, especially during the placement and finishing stages)

Examples of Wired Thermocouples with External Loggers

Command Center by Transtec Group Inc.

These wired loggers are embedded in concrete. The wired lead can be connected to a hand-held device, such as a phone or tablet, to download to the data. You can also attach the logger to a wireless transmitter to send the data to a mobile device wirelessly on the jobsite.

Con-Cure by Nex

The Con-Cure’s wired concrete temperature loggers are also embedded in concrete. The wire lead can be connected to a hand-held device to download the recorded data, or to a wireless node that will transmit the data to the cloud through cell network. You can also save the data on an SD card.

2. Fully-Embedded Wireless Concrete Sensors

Throughout the years there have been major advances in concrete-testing technology that make the process of testing much easier than common concrete temperature loggers. Fully embedded wireless sensors can be installed in the forms prior to the pour and temperature wires can be extended to the appropriate locations within the concrete form. Once the concrete is poured, the sensors and wires are completely covered, and no system components are exposed out of the concrete. Data is collected using wireless communication through a free mobile app. This application performs automatic maturity and strength calculations (as long as a calibration curve is provided) and the information can be conveniently shared with the team for collaboration and data viewing.

Pros

- Real-time data collection allows project members to make timely and well-informed decisions

- Data can be accessed anywhere from a smartphone device or tablet through wireless communication

- Completely wireless with no physical connection needed to transmit data

Cons

- Loggers must be placed within a certain distance from the surface of the concrete to ensure effective connectivity

Examples of Fully-Embedded Wireless Sensors

Concrete Sensors by Hilti

This sensor is a fully embedded sacrificial sensor that records both temperature and humidity of concrete. The data can be seen and analyzed using Concrete Sensor’s mobile application wirelessly.

Converge Signal

The Converge Signal sensor is a fully embedded wireless sensor that is embedded in the concrete. The data is sent wirelessly to either a mobile device or a local hub, and then to the cloud through cell network.

HardTrack by Wake Inc.

The HartTrack sensor has a temperature measurement cable that is connected to an RFID reader. The RFID can either be embedded in the concrete or placed outside to be reused. You can use the RFID reader to retrieve the recorded data or install a local hub to wirelessly download the data.

SmartRock® by Giatec

Giatec’s SmartRock sensors are fully embedded sensors that record data wirelessly. This data is sent via Bluetooth® to a mobile device. The data can be analyzed either using the free mobile app in real-time on the jobsite or on the Giatec 360™ cloud dashboard. In the Giatec 360 platform, you can create a thermal modeling scenario and predict temperature differentials.

SmartRock Pro by Giatec

SmartRock Pro is an advanced, fully embedded wireless sensor that builds on the core features of the original SmartRock with real-time monitoring, cloud syncing via Giatec 360, and remote data access through SmartHub. In addition to these capabilities, SmartRock Pro introduces self-calibrating, mix-independent strength estimation using Giatec’s proprietary CEMMA technology, eliminating the need for manual calibration or mix-specific inputs. Its probe is embedded before the pour, while the transmitter remains near the surface for enhanced wireless connectivity and long-range data transmission.

Learn more about the Giatec 360 Cloud Dashboard here!

vOrb by Quadrel

This sensor uses Wi-Fi communication and is embedded in the concrete. The data needs to be retrieved via a local hub before it is transmitted to the cloud.

Frequently Asked Questions

How Do I Use a Temperature Logger on a Concrete Pour?

Install the sensor or thermocouple in the formwork before the pour. Make sure it’s secure and in the right spot for accurate temperature reading. After the pour, monitor through the app or external logger, depending on the type.

Are Temperature Sensors for Concrete Reusable?

Most wireless sensors are single-use and stay in the concrete. Some wired systems with external loggers can be reused if the thermocouple and logger can be retrieved without damage.

How Accurate Are Temperature Sensors in Concrete?

Good loggers are ±0.5°C or better. Accuracy depends on sensor placement, calibration, and protection during the pour.

Can Concrete Temperature Sensors Detect Thermal Gradients?

Yes. Installing multiple sensors at different depths or areas will allow you to detect internal temperature differentials. This is especially useful for mass concrete pours to prevent thermal cracking.

How Often Do Temperature Loggers Record Data?

Most loggers record every 5 to 30 minutes. Some can be customized depending on your monitoring needs and battery life.

Do I Need Calibration for Using a Temperature Logger with the Maturity Method?

Yes. To use temperature data to estimate concrete strength you need to generate a strength-maturity calibration curve for your concrete mix following ASTM C1074.

Sources

Note: All company, product/service names, and brands used in this article are property of their respective owners. This article is intended to be used for informational purposes only.

*Editor’s Note: This post was originally published in April 2021 and has been updated for accuracy and comprehensiveness as of May 2025.