At Giatec, we understand the importance of elevating the quality of your construction project. Building concrete structures often comes with a myriad of challenges and hectic activities at the job site. For that reason, it is important for general contractors and project managers to properly address key aspects of concrete pouring. In this blog, let’s examine some of the quality control actions that are relevant during the process of concrete pour.

Got the game on? Don't miss a shot with SmartRock® in hand.

General Stages of the Concrete Pouring Process

- Pre-Pour Inspection

- Concrete Pour

- Post-Pour

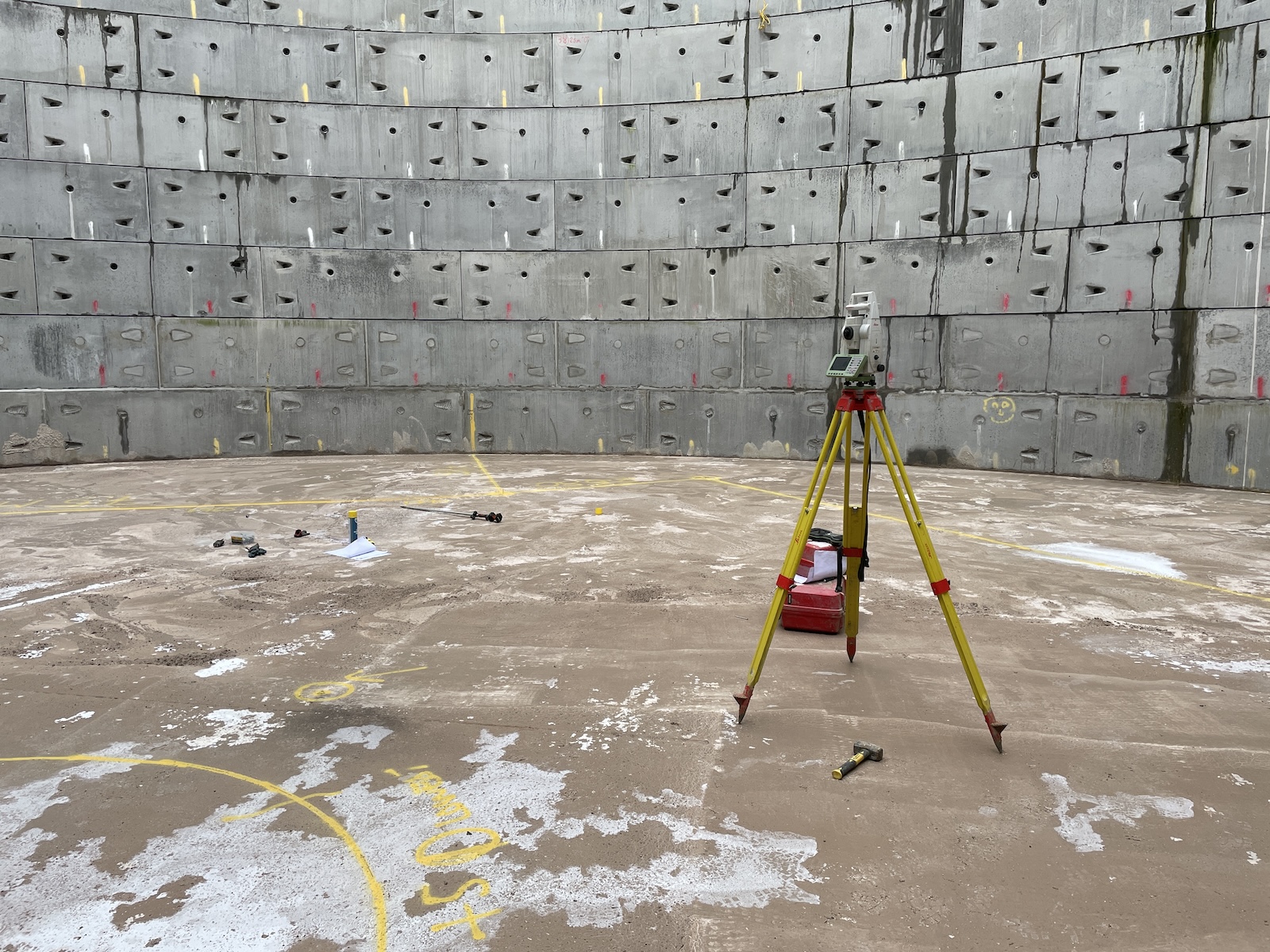

1. Pre-Pour Inspection

At this stage, general contractors review essential details such as structure drawings, rebars, cover depth, waterproofing systems, form, schedules, testing agencies, weather conditions, mix design, placement equipment, and other project specifications.

2. Concrete Pour

At this stage, general contractors focus on everything related to the concrete mix. Some of the things to oversee are the concrete tickets, the properties of the first loads, properties for hardened concrete, samples, delivery rates, assessment of the discharge time, the properties of the loads, the jobsite nuances, and the monitoring systems essential for the curing period.

3. Post-Pour

Stage 1

This stage is divided into two parts. First, general contractors carefully follow the curing schedule, ensure protection from changing weather conditions, keep track of the temperature and maturity data provided by concrete sensors, as well as account for thermal control and strength measurements.

Stage 2

Lastly, the second stage is about exporting data for quality control, formwork removal, and concrete finish for cracks, imperfections, and other conformance and non-conformance issues.

Adopting the Best Quality Is Now Easy With the Concrete Pour Checklist

Carefully managing your concrete pours will ensure an optimal streamline of the construction process from start to finish. You too can implement the best practices with the Quality Control Checklist aimed at helping you perform a stress-free concrete pour.

This checklist provides general contractors free access to a comprehensive list of action items to facilitate compliance, minimize risks, and guarantee a successful process. So, start transforming your concrete control and download your checklist for free.