Concrete production has never lacked data. It has lacked a system that can turn data into timely, coordinated action. An AI-powered operating system (AI OS) changes that by shrinking decision latency from days to minutes across the entire pour cycle.

Build Data Centers Faster with SmartRock® Long Range

In this blog, let’s explore how AI-powered operating systems are reshaping concrete production by reducing variability, shortening decision latency, and enabling real-time optimization, from batching through curing.

The AI-Powered Operating System Shift

Concrete leaders have lived through three waves of digital change: plant automation, connected fleets, and analytics dashboards. Each wave improved visibility, but none solved the root problem: decisions still arrive too late to change outcomes. In this transformative era, the conversation has moved from “AI tools” to AI as the operating layer that governs how work gets done, end-to-end.

What’s an AI-Powered Operating System?

An AI OS is an orchestration layer that coordinates models and agents across your existing stack, such as cloud data platforms, ERP, dispatch, batching systems, PLCs, and field apps. Its job is not to replace your systems. Its job is to conduct them: sense conditions, predict outcomes, and trigger real-time adjustments, while logging every decision for auditability.

AI OS in Practice: Sensors, Transport, and Cloud Coordination

Think of it as the enterprise control plane for concrete performance. ERP tells you what happened financially. An AI OS tells you what is happening operationally, what will likely happen next, and what adjustment reduces risk while protecting margin and schedule. This is why point solutions struggle to scale. They produce insights, but they do not own the decision loop.

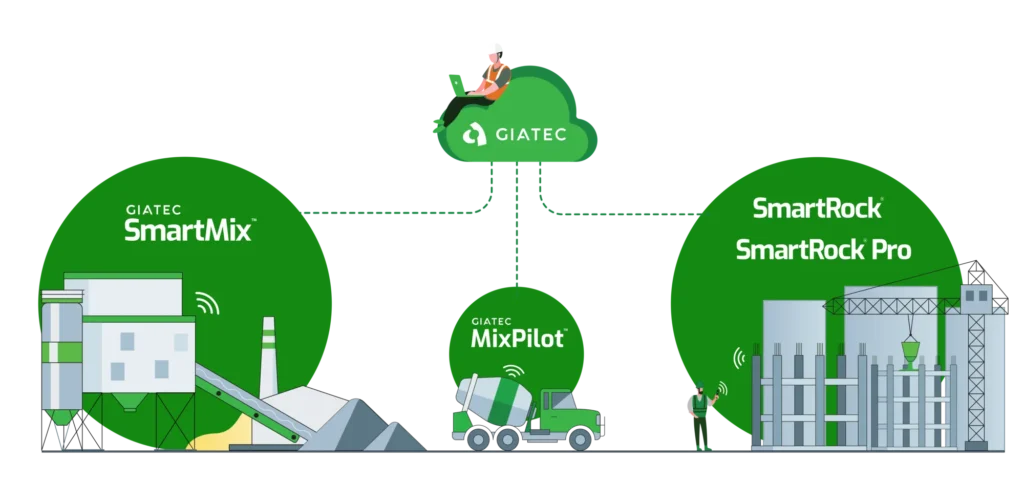

At the operations level, the building blocks for an AI-powered operating system are already in place across the industry. Embedded sensors, in-transit monitoring, and cloud-based coordination platforms now make it possible to connect batching, delivery, placement, and curing into a single operational loop. Together, these components allow concrete performance to be monitored continuously rather than inferred after the fact.

From Sensors to System-Level Coordination

Several technology providers illustrate how these pieces can come together in practice. For example, Giatec’s ecosystem demonstrates one implementation path, combining embedded maturity sensing (SmartRock® and SmartRock Pro), real-time visibility during transport (Giatec MixPilot™), and system-level coordination through cloud platforms such as Giatec 360™ and Giatec SmartMix™.

Once an organization operates with real-time confidence in strength development, closed-loop control of workability, and the ability to learn across pours and plants, reverting to manual sampling and delayed feedback becomes a structural disadvantage.

This shift is not about adopting another digital tool. It marks a transition from using data for retrospective reporting to using it as a live operating signal that actively governs performance.

Concrete Pour Cycle Challenges

Concrete does not fail as a single event. It fails as a chain of small variances that compound across batching, transport, placement, and curing. The challenge is that traditional quality systems observe that chain in snapshots.

At batching, moisture swings, aggregate gradation drift, and temperature fluctuations change water demand and early hydration behavior. Minor deviations in w/cm and mixing energy can create segregation risk before a truck leaves the plant.

During transport, the truck becomes a “factory in transit.” Heat, delays, drum speed, and time all change workability. Slump loss and improper retempering can erode strength and durability even if the batch ticket looked perfect.

At placement, workability variability shows up as honeycombing, poor consolidation, finishing challenges, and higher variability in in-place properties.

In curing, uncertainty forces conservative timelines. When teams cannot trust when concrete will hit stripping or stressing strength, they pad schedules and add cement as insurance. That protects risk, but it inflates cost and embodied carbon.

Common Failure Points Across the Pour Cycle

The underlying problem is decision latency: the gap between the physical event and the moment the organization can react. Cylinder breaks can take days. Scheduled sampling can miss transient variability. Manual slump tests are operator-dependent and not continuous, limiting their usefulness during placement.

Here are the most common pain points, with the business impact hiding behind them:

- Overdesign cement: extra cement added “just in case” increases cost per cubic yard and raises CO₂ intensity.

- Rejected loads and rework: variability discovered late leads to removals, repairs, or dispute risk.

- Conservative curing delays: schedule buffers added because strength timing is uncertain.

- Inconsistent slump control: workability drift during transport drives placement defects and downstream variability.

- Fragmented data: plant, dispatch, fleet, and jobsite data do not share a learning loop, so the same mistakes repeat.

A mature AI OS targets these pain points by turning the pour cycle into a closed loop: sensing → prediction → adjustment.

How AI OS Supports Concrete Operations

An AI OS is not “more sensors.” It is a system that makes existing sensors and software act like one coordinated machine.

Sensing

At the plant level, sensing starts with production signals such as batch weights, aggregate moisture, material temperatures, and mixing energy proxies. These inputs establish the baseline conditions that determine early hydration behavior and workability before concrete ever leaves the plant. When captured continuously, plant signals help reduce variability caused by raw material fluctuation and batching drift, enabling more consistent production outcomes.

Across the fleet and transport stage, in-transit monitoring technologies extend visibility beyond the plant gate. Non-invasive hardware combined with advanced sensing and analytics is increasingly used to track workability, temperature, and mixing behavior from plant to pour. Continuous monitoring during transport allows teams to observe slump drift in real time rather than discovering issues only at discharge, helping address long-standing challenges related to delays, retempering, and rejected loads across ready-mix operations.

At the jobsite, embedded sensing provides direct insight into what matters most: how concrete is actually behaving in place. Sensors installed within structural elements measure temperature and maturity continuously, shifting curing decisions from inference based on ambient conditions to direct measurement of in-situ performance. Some systems incorporate self-calibration and mix-agnostic approaches to reduce setup effort when designs change, supporting consistency across pours, projects, and plants.

Prediction

Prediction translates raw signals into forward-looking insight that allows teams to act before variability turns into defects. In a concrete AI OS, prediction operates across the same three stages as sensing, ensuring continuity from production to placement.

At the plant level, predictive models estimate how material properties, proportions, and mixing conditions will influence early-age behavior. This includes forecasting strength development trends, setting characteristics, and sensitivity to temperature or moisture variation. These predictions support mix-level decisions before concrete is dispatched.

Across the fleet and transport stage, prediction focuses on how time, temperature, and handling will affect workability and performance. By combining plant data with transport conditions, the system can anticipate slump loss, segregation risk, or excessive retempering before the truck arrives onsite.

At the jobsite, prediction centers on in-place outcomes. Temperature histories and maturity data are used to forecast strength gain, stripping or stressing readiness, and thermal risk. The goal is not perfect accuracy, but early, reliable guidance that supports economically correct decisions while concrete is still adjustable.

Adjustment

Adjustment is where prediction becomes operational control. Rather than reacting after results are known, an AI OS enables targeted interventions across the same three stages, within defined safety and governance boundaries.

At the plant level, adjustments may include fine-tuning water or admixture dosing, modifying batching sequences, or selecting alternative proportions within approved limits. These actions are designed to counter predicted variability before it propagates downstream.

Across the fleet and transport stage, adjustment focuses on managing workability during transit. Guidance on dispatch timing, controlled mixing energy, or hold strategies helps stabilize concrete properties before placement, reducing the likelihood of rejection or corrective action onsite.

At the jobsite, adjustments are primarily related to curing and scheduling decisions. Based on predicted strength and thermal behavior, teams can optimize curing methods, stripping timing, or stressing windows. These interventions reduce conservative buffers while maintaining safety and performance.

Adjustment is where AI becomes an operating system rather than analytics. In concrete operations, adjustment typically happens through three pathways:

- Plant adjustments: water and admixture tuning, cement and SCM optimization, mixing sequence control.

- In-transit adjustments: guidance on drum RPM, hold times, or targeted corrections under controlled rules.

- Curing adjustments: timing, insulation/heating actions, formwork and stressing decisions.

The strategic promise is closed-loop control: the system detects drift, predicts consequence, and triggers the smallest safe adjustment that protects performance.

Integration

Integration is the difference between a pilot and a scalable operating model. A true AI OS overlays existing hardware and software rather than ripping it out. It connects to batch systems and PLCs, ingests IoT and telematics feeds, and writes insights back to the systems people already use.

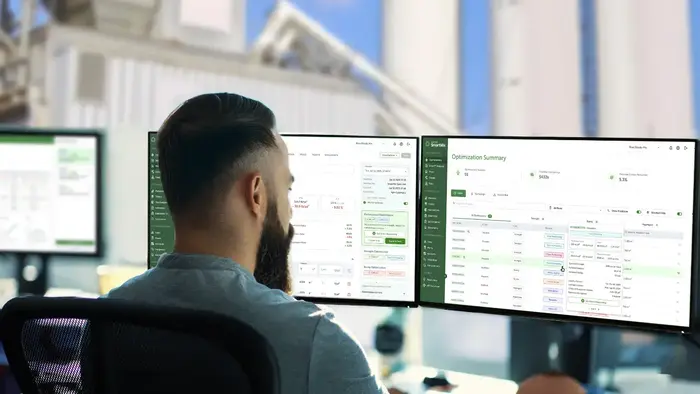

At the plant and quality level, integration focuses on learning from production outcomes and feeding that intelligence back into future mix decisions. AI-driven mix optimization systems increasingly rely on large, cross-plant datasets that capture how different materials, proportions, and conditions influence performance. When mix outcomes are logged systematically, each batch becomes training data, allowing recommendations to improve over time and insights to transfer across plants rather than remaining locked in local experience.

Across the fleet and production network, integration requires a shared operational record that links plant decisions to delivery and placement conditions. Centralized platforms aggregate data from multiple sources: batching systems, in-transit monitoring, and jobsite feedback, so performance can be evaluated in context rather than in isolation. This cross-stage visibility is what enables organizations to distinguish material issues from transport or handling effects.

At the jobsite and system level, integration comes together through cloud-based coordination layers that centralize real-time concrete data and support predictive, action-oriented oversight. When in-place sensing, delivery data, and production history are visible through a single interface, the system functions as an operational control plane: unifying visibility, preserving traceability, and enabling decision support across pours and projects.

Modern Concrete & Materials brought their manual spreadsheet work down from 4-5 days to just 1 hour. Learn how SmartMix helped!

Enterprise Considerations for AI Operating Systems

With the technical foundations established, the next question is how adopting an AI operating system changes decision-making, governance, and operating models at the organizational level.

This section consolidates the core considerations that consistently surface when organizations evaluate the adoption of an AI operating system. Rather than presenting them as individual questions, the points below reflect the practical decision framework teams use when assessing readiness, value, and scale.

- Role of the AI OS vs. traditional platforms: An AI OS differs from reporting or analytics platforms by owning orchestration. Traditional systems store data and describe past performance. An AI OS coordinates workflows, predictions, and actions across tools through a unified control layer, enabling decisions to be made while outcomes are still adjustable.

- Integration without rip-and-replace: AI operating systems are designed to sit above existing PLCs, batching software, dispatch systems, and sensors. They ingest signals through APIs and gateways, then feed recommendations back into familiar workflows. Adoption typically begins in advisory mode and advances toward automation only where confidence and risk tolerance allow.

- Primary ROI drivers: The most durable returns come from cement optimization, reduced rework, fewer rejected loads, and schedule compression enabled by earlier strength certainty. These levers directly affect unit cost, risk exposure, and throughput rather than relying on marginal efficiency gains.

- Critical system capabilities: Effective AI OS deployments require continuous data ingestion, robust model governance, traceable decision logs, and the ability to execute closed-loop adjustments within boundaries defined by operators and engineers.

- Governance and risk management: Governance is primarily operational. It defines who can authorize automated actions, what confidence thresholds trigger intervention, and how decisions are logged for auditability. This framing is more actionable than abstract discussions of AI ethics.

- Operating model and leadership impact: Adoption changes how teams work. Responsibility shifts from manually policing quality toward supervising system performance, managing exceptions, and continuously refining rules, targets, and recipes based on observed outcomes.

- Vendor lock-in considerations: Long-term flexibility depends on data ownership and modular design. Organizations should retain control of their operational history and be able to evolve sensing, analytics, or execution components without dismantling the entire system.

- Technical foundation: At its core, an AI OS is an orchestration problem. Reliable data pipelines, strong identity and access controls, system monitoring, and disciplined model lifecycle management form the technical backbone that enables safe scaling.

- Investment focus and KPIs: Early metrics should prioritize decision latency and its downstream effects, including cement variability, strength dispersion, rejection rates, and time-to-strip or time-to-stress. These indicators reveal whether the system is materially changing outcomes.

- Near-term adoption trajectory: A realistic 12-18-month path includes advisory recommendations within months, targeted closed-loop control in defined scenarios within a year, and compounding benefits from cross-plant learning as the operational dataset grows.

With these enterprise considerations in place, the focus can shift from strategy to execution, how AI OS capabilities translate into concrete operational gains on the plant floor and jobsite.

KPI Optimization: Simultaneous Optimization of Cost, Quality, Carbon Footprint

Beyond technical capability, the value of an AI operating system lies in how it enables organizations to balance cost, performance, and sustainability in real time rather than optimizing each dimension in isolation.

Concrete operations rarely optimize a single target. You balance cost, performance, schedule, and sustainability, often under constraint.

An AI OS makes multi-objective optimization practical by continuously rebalancing trade-offs in real time. Meta’s approach to lower-carbon, faster-curing formulations, explicitly treats mix design as a multi-objective problem under constraints, illustrating how AI can search an outcome space faster than manual trial-and-error.

Linking AI OS Capabilities to Measurable Outcomes

The table below summarizes how an AI OS can link key KPIs to mechanisms and practical impacts.

| KPI | Issue | AI Mechanism | Impact |

| Cement factor | Overdesign from uncertainty | Predictive strength + mix optimization | Lower cement use with tighter strength control |

| CO₂ intensity | High clinker dependence | SCM optimization + performance forecasting | Reduced embodied carbon from optimized binder use |

| Rework rate | Late detection of variability | Closed-loop monitoring and alerts | Fewer removals, fewer disputes |

| Slump compliance | Drift in transit/placement | Real-time sensing + corrective rules | Less rejection, smoother placement |

| Decision latency | Days-long feedback loops | Continuous sensing + maturity-based triggers | Hours → minutes for key calls |

Across the industry, AI-driven mix optimization approaches are increasingly used to prescribe more cost-efficient proportions while improving consistency in field performance. By linking material selection, proportioning, and early-age performance data, these systems directly address the long-standing issue of cement overuse as both a cost driver and a source of unnecessary embodied carbon.

In parallel, AI-powered vision and sensing technologies are being developed to automate slump and workability assessment. These approaches highlight a core limitation of manual slump testing: it is intermittent and highly operator-dependent, making it unsuitable for continuous control during placement. Continuous, automated measurement aligns more closely with how concrete actually behaves over time.

Within an AI OS framework, optimization becomes a real-time balancing act that occurs during production and placement, when adjustments can still influence outcomes.

Build Data Centers Faster with SmartRock® Long Range

Operator Evolution: From Batchman to AI Conductor

As control shifts from manual adjustment to AI-supervised systems, roles on the plant floor and jobsite evolve from hands-on intervention to oversight, decision support, and exception management.

AI OS adoption does not eliminate expertise. It changes how expertise is applied. In a traditional plant, skilled operators spend time on repetitive adjustment and firefighting: moisture swings, unexpected slump loss, and late quality signals. In an AI OS model, the system performs continuous monitoring and recommends the smallest corrective action, while operators supervise performance and handle exceptions.

This shift resembles what closed-loop AI has done in other process industries: operators define boundaries, the AI optimizes within them, and override authority stays available.

Imubit’s cement-industry perspective emphasizes that AI-powered systems can preserve operational wisdom while augmenting human expertise; an important point in an industry facing retirements and talent gaps.

In concrete operations, this evolution can be structured as a maturity path:

- Advisory: The system flags drift and suggests adjustments.

- Assisted control: Operators approve recommended actions through dashboards.

- Automation in bounds: Defined adjustments execute automatically when confidence thresholds are met.

Giatec’s MixPilot narrative reinforces this “people-first” dynamic by positioning real-time slump and load data as empowerment for drivers and QC teams, not replacement.

Upskilling shifts toward:

- Data fluency (reading trends, not just tickets)

- Troubleshooting sensors and system health

- Using dashboards to manage multiple plants or projects

- Translating operational insight into repeatable rules

The outcome is a more scalable operating model: fewer surprises, fewer late-night calls, and knowledge captured in learning loops.

Concrete-Specific Operational Considerations

After exploring enterprise- and human-level impacts, the discussion now turns to the practical realities of concrete production, where material behavior, standards, and field conditions impose unique constraints.

This section focuses on concrete-specific operational considerations when applying an AI operating system in real production environments, covering how sensing, control, governance, and long-term applicability play out on the ground.

- Role of AI sensing alongside manual testing: AI-based sensing does not eliminate manual testing overnight. Its primary value is in reducing reliance on infrequent snapshots by adding continuous signals that improve confidence between tests. Embedded, in-place measurements allow teams to observe curing behavior directly rather than infer it from external conditions.

- Meaning of closed-loop control in concrete operations: Closed-loop control refers to a system’s ability to detect drift, predict its impact on performance, and either trigger a corrective adjustment or escalate to human oversight before the drift becomes a defect.

- Critical data signals: The most useful inputs include temperature histories, maturity development, batch proportions, drum behavior proxies during transport, ambient conditions, and delivery timing. Together, these signals describe how concrete evolves from plant to placement.

- Interpreting prediction accuracy: Accuracy improves as datasets grow and become more relevant, but the objective is economically correct action rather than perfect forecasts. Guardrails, confidence thresholds, and escalation logic keep interventions safe and controlled.

- Scope of real-time adjustments: Practical adjustments include admixture tuning, dispatch and delivery timing, and curing actions. Adoption typically begins in bounded scenarios where the cost of error is low, and confidence can be built incrementally.

- Impact on schedule and rework: Operational benefits often appear as fewer rejected loads, smoother placement, and earlier confidence in stripping or stressing decisions, reducing both delay risk and corrective work.

- Cement and CO₂ reduction mechanisms: Emissions and cost reductions primarily come from cutting overdesign and prescribing mixes that meet performance requirements with lower clinker content, enabled by stronger confidence in early-age performance.

- System change requirements: Most deployments emphasize integration rather than replacement, connecting batching systems, fleet data, and jobsite sensing into a shared operational record.

- Certification and governance alignment: Governance improves when systems log decisions and maintain traceable records of inputs, predictions, and actions. Approaches that reduce calibration friction when mixes change further support consistent application across projects.

- Longer-term roadmap: Over a five-year horizon, the trajectory points toward autonomous quality control in defined scopes, including continuous workability assessment, maturity-driven scheduling, and cross-plant optimization informed by live outcomes.

Actionable Roadmap

The AI operating system concept can be a practical, time-phased adoption path for concrete operations. It answers a simple question: how does an organization move from today’s fragmented quality controls to an AI OS that actively governs concrete performance without overreaching or disrupting production? The roadmap below reflects how most successful deployments progress in practice.

0-12 months: Establish the foundation

The first phase focuses on readiness rather than automation. The objective is to build trust in data, decisions, and governance while demonstrating value in targeted use cases.

- Establish governance and decision authority: Define who can approve recommendations, which confidence thresholds trigger action, and when decisions escalate to human oversight. Clear rules early prevent friction later.

- Instrument the pour cycle: Prioritize visibility where uncertainty is highest. Embedded maturity sensing at the jobsite and in-transit workability monitoring provide immediate insight into curing and slump behavior that traditional testing cannot capture in real time.

- Run concrete-first pilots: Select use cases where the value of faster decisions is obvious: high-risk structural pours, fast-cycle schedules, or repetitive, high-volume mixes. These environments surface learning quickly and limit downside risk.

- Centralize operational visibility: Consolidate plant, fleet, and jobsite data into a single operational record. Standardized dashboards and reporting create a shared view of performance and form the backbone of future learning.

12-24 months: Scale and Connect

Once confidence is established, the focus shifts from isolated pilots to coordinated operation across plants and projects.

- Expand across plants and priority projects: Apply proven workflows to additional sites, maintaining consistent governance and performance metrics while accounting for local material and operational differences.

- Activate cross-plant learning loops: Use outcomes data to continuously refine mix recommendations, operating rules, and performance targets. Learning no longer stays local; improvements in one plant inform decisions in others.

- Move toward assisted control: Transition from advisory insights to assisted execution in bounded scenarios such as admixture tuning, dispatch timing, or curing triggers. Operators remain in control, but the system increasingly drives consistency.

24+ months: Operate as a system

In the final phase, the AI OS becomes part of how concrete operations are run day to day.

- Adopt the AI OS as the operational system of record: Treat the platform as the authoritative source for concrete quality, performance history, and decision traceability across the organization.

- Automate closed-loop adjustments within limits: Enable automatic interventions where confidence is high and risk is low, while preserving human oversight for edge cases and complex decisions.

- Manage decision latency as a core KPI: Track how quickly the organization can detect, decide, and act on variability. When decision latency is actively managed, delayed, manual quality control becomes the exception rather than the operating norm.

By progressing from foundation to scale to system-level control, AI operating systems become less of a technology initiative and more of a new operating model for concrete performance.

Conclusion

AI-powered operating systems mark a fundamental shift in how concrete production is managed. Rather than adding another layer of analytics, an AI OS acts as an operational control plane: connecting plant, fleet, and jobsite signals into a continuous loop of sensing, prediction, and adjustment. This shift directly addresses long-standing challenges in the concrete pour cycle: variability, delayed decisions, overdesign, rework, and unnecessary carbon intensity.

By reducing decision latency and enabling closed-loop control, AI OS platforms allow concrete teams to balance cost, quality, schedule, and sustainability in real time, not after the fact. The impact is not limited to individual pours or projects; learning compounds across plants and over time. As adoption progresses from advisory insights to assisted and automated control, organizations move from reporting on outcomes to actively governing them. The result is a more resilient, scalable, and performance-driven operating model for concrete production.

Data siloes can stall your ready-mix operations. Learn how to you can optimize your workflows!