Precisely monitor the temperature of your concrete structures under any conditions

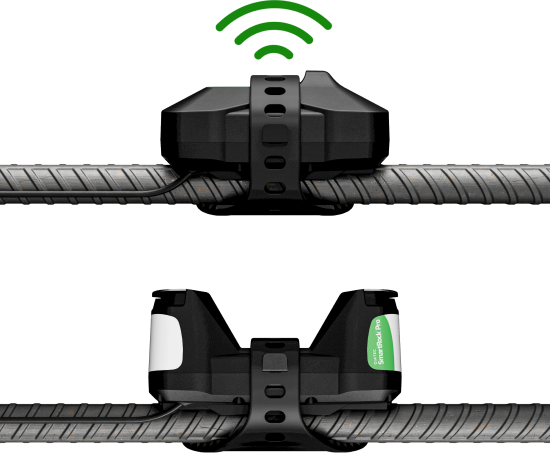

Collect real-time in-situ concrete strength data through maturity-based sensors

Maturity-Based Concrete Strength Monitoring

Self-Calibrating Concrete Strength Monitoring

AI-powered precision for every concrete mix for the Producers

Instant ROI

AI-Powered Decision Making

Drive Sustainability

Core Quality Control

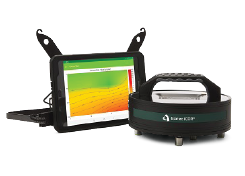

Corrosion detection in concrete reinforcement

Concrete quality detection lab equipment

Experts revolutionizing the construction industry

Stay on the cutting edge of concrete tech

Save the date and join us at future events and conferences

Construction management isn’t just about moving dirt and pouring concrete; it’s about managing a complex web of contracts (including defining risks, quality control, and dispute management), scheduling and planning, as well as safety, to bring a vision to life. Whether you’re overseeing road repair or a mass concrete project, the core principles of effective construction management remain the same. If executed well, this will ensure that your project is completed on time, within budget, and meets the highest standards. In this blog, we’ll examine key insights that will help you deliver projects more successfully and efficiently. Why Clear Contracts are Essential for Effective Construction Management When it comes to construction, contracts are more than just legal formalities; they form the foundation of the entire project. A good contract defines responsibilities, sets expectations, and outlines the rules that everyone involved must follow. Without a solid contract, you’re setting yourself up for confusion, delays, and costly disputes. A well-crafted contract should: How to Navigate Construction Risks with Proactive Management Strategies In construction, risks are inevitable—whether it’s unpredictable weather, labor shortages, or unexpected site conditions. What separates successful projects from the ones that falter is how risks are identified and mitigated from the outset. A good project manager…

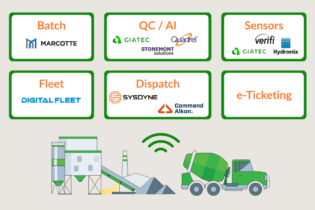

Digital transformation is reshaping the concrete production industry, offering opportunities to streamline operations, enhance efficiency, and improve customer satisfaction. From automating batch processes to integrating logistics and delivery systems, concrete producers are leveraging innovative concrete production automation technologies to stay competitive. However, this transformation comes with challenges, including system integration, managing increasing data volumes, and addressing cybersecurity risks in a connected production environment. Understanding these challenges is vital for producers looking to future-proof their operations. In today’s evolving market, concrete producers must adapt to changing customer demands and operational complexities. Whether it’s embracing concrete production automation in material handling, utilizing cloud-based platforms for scalability, or implementing e-ticketing for improved logistics management, the key to success lies in adopting the right strategies and technologies. This post explores the critical challenges and emerging trends shaping the concrete production industry and provides actionable insights to help producers optimize their processes and remain at the forefront of the market.Key Challenges in Technology Adoption Essential IT Solutions for Concrete Producers Organizations are leveraging a diverse array of technologies to tackle these challenges. The concrete and ready-mix industry heavily relies on tailored platforms to manage its specialized operations, from batching to dispatching and beyond. Below is a detailed review…

On any job site, the strength of a concrete pour is a critical piece of information. A concrete cylinder test or concrete break test has been the pillar for compression strength testing in the construction industry for more than 180 years (Concrete Network).How do Third-Party Labs Perform a Concrete Cylinder Test?There are two types of specimens that field technicians collect to test the strength of concrete (in accordance with ASTM C31): Standard-Cured Cylinders Field-Cured Cylinders As the name suggests, field-cured cylinders are subject to the same temperature and relative humidity levels that the completed structure will experience in its environment. Unlike standard-cured cylinders, field-cured specimens are kept right beside the concrete slabs on site. They are predominantly used for determining whether a structure is ready for critical operations like removing formwork, tensioning, and road openings.In standard or lab curing, concrete test cylinders are sent to the lab and subjected to standard temperatures and humidity conditions —23.0 ± 2°C and relative humidity that’s greater than 95% as outlined in the project’s specifications. They are generally used for quality control and standard acceptance purposes.Lab StepsWhen the specimen (e.g. drilled cores and molded cylinders) is ready to be tested in the lab, the…

Visit our careers page to learn about our award-winning culture and our open positions.

The concrete game has changed. Find out what self-calibrating sensors can do for you with Giatec’s SmartRock® Pro.