When talking about the “Plant of the Future”, it’s easy to picture something out of science fiction. Fully autonomous operations, driverless trucks, or radically different infrastructure often come to mind. In reality, the future of concrete production is far more practical and far more achievable.

Want to take the guesswork out of concrete slump?

At Giatec, we work alongside forward-thinking producers and technology partners to help shape that future by bringing proven solutions together into one connected ecosystem. Through these collaborations, like with Tomlinson Ready-Mix, we’re helping turn the “Plant of the Future” into a practical reality by connecting plant, in-transit, and jobsite data to support smarter decision-making and ready-mix production optimization.

In this blog, we’ll explore what the “Plant of the Future” really means for ready-mix producers today, and how connected data and AI are enabling more consistent, confident ready-mix production optimization.

Viewing Ready-Mix Operations as a Connected System

Concrete producers manage complex operations every day. Material costs fluctuate, production must remain consistent, deliveries need to be precise, and quality expectations continue to rise. At the same time, producers are balancing labor availability, customer satisfaction, and energy use.

These challenges don’t exist in isolation. Yet across the industry, the data needed to address them often is. Concrete plants generate billions of data points through batching systems, dispatch platforms, material sensors, in-transit monitoring tools, and jobsite performance tracking. The problem is that this information is scattered across platforms, teams, and stages of production, making it difficult to see the full picture of concrete performance or operations in real time.

How Giatec Connects the Concrete Lifecycle

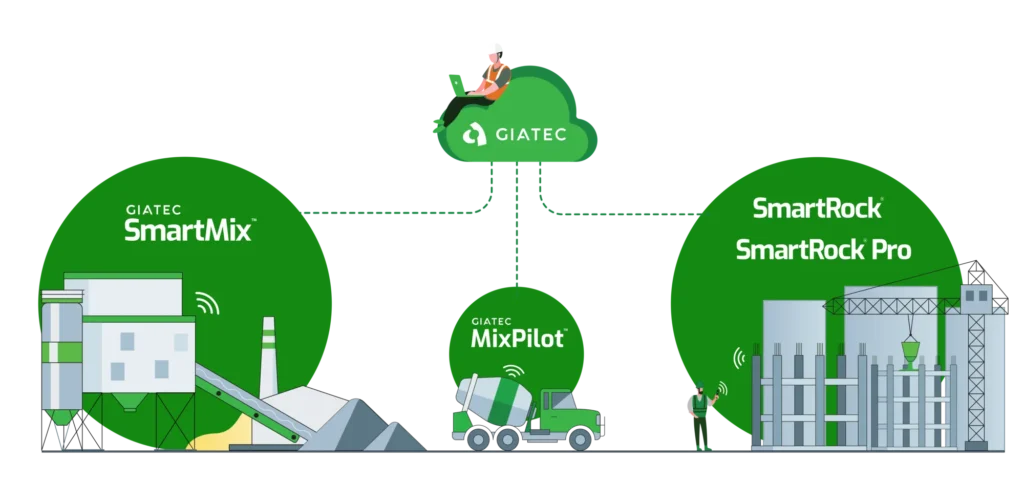

This is why the “Plant of the Future” is about connecting the technologies already in place. At Giatec, we are building that connectivity through Giatec SmartMix™, bringing data from across the concrete lifecycle into one environment and analyzing it through Roxi™, our AI engine, to generate insights producers can act on with confidence.

Rather than replacing the systems producers already rely on, SmartMix is designed as an open platform that integrates with plant, materials, delivery, and jobsite technologies:

- Giatec MixPilot™ provides non-invasive, self-calibrating, in-transit slump monitoring that helps teams track delivery conditions, including concrete slump, temperature, and volume.

- alterBiota’s digitalAggregate™ adds real-time aggregate gradation insight at the plant, helping producers understand material variability before it impacts performance.

- CiDRA’s SMARThatch extends in-transit visibility with continuous quality measurement from the plant to the jobsite, including air content measurement.

- Digital Fleet supports in-transit visibility and fleet tracking, strengthening continuity from dispatch to delivery.

- Climate Earth sustainability reporting by enabling access to Environmental Product Declarations (EPDs).

This connected ecosystem is what enables ready-mix production optimization at a system level, improving performance across:

- Raw materials and mix design

- Production, dispatch, and delivery

- Product quality and performance visibility

- Operational efficiency and customer satisfaction

Improving each of these areas together is the only way to create meaningful, lasting change and move toward a fully connected, future-ready concrete operation.

Plant of the Future in Action: Tomlinson Ready-Mix

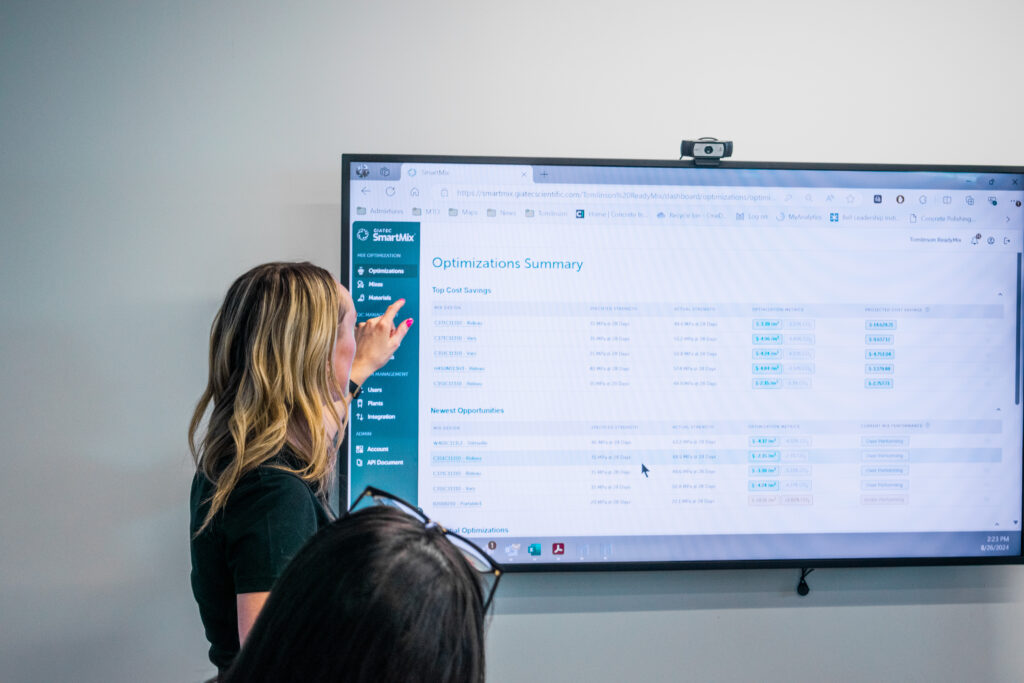

Tomlinson Ready-Mix is one of several forward-thinking producers working with Giatec to bring the “Plant of the Future” to life. Through this collaboration, SmartMix is being applied in real operations to connect plant, QC, and delivery insight into a single operational view of performance.

This is further enabled through SmartMix’s ecosystem of integrations with technology providers across the value chain, including material intelligence solutions such as alterBiota, and in-transit visibility partners, such as CiDRA. By connecting these systems into one data backbone, producers gain stronger lifecycle visibility and can maintain confidence in optimized mixes as conditions change.

Giatec’s and Tomlinson’s shared vision for the future of ready-mix concrete was showcased at our 2nd Annual Concrete Tech Summit in 2025, where the “Plant of the Future” reveal highlighted how ecosystem partners, connected sensors, and AI-powered decision-making are shaping next-generation operations.

[CTA] With SmartMix, Tomlinson saved 5% on costs and used 8.8% less cement on their overdesigned concrete mixes. Read the full case study!

The Missing Link in the Industry

The challenge for many producers is a lack of integration between technologies. Batching and dispatch data may live in one platform, QC data in another, material data in separate reports, and in-transit metrics tracked elsewhere or not at all.

In practice, teams are forced to bridge these gaps manually through spreadsheets, exports, and re-entry. This slows decision-making, makes it harder to trace root causes, and reinforces a reactive way of working. Even when a mix is optimized, that optimization is difficult to maintain because there is no consistent feedback loop from plant to transit to placement.

Data silos can hinder operational efficiency. Learn more about open systems in concrete operations!

Building the Architecture for the Plant of the Future

Across the value chain, there are powerful point solutions for batching, dispatch, material management, in-transit monitoring, QC systems, testing, and jobsite performance tracking. The “Plant of the Future” is defined by a connected architecture that brings these systems together to support better decisions from plant to pour.

Giatec is building that architecture through SmartMix and an open integration strategy. By connecting technologies and partners such as alterBiota, CiDRA, Command Alkon, and Climate Earth, SmartMix enables unified plant-to-pour visibility that supports proactive quality management and more confident decision-making across the operation.

This ecosystem momentum is further reinforced through strategic partnerships such as Giatec’s investment partnership with Sika, helping accelerate global adoption of connected, data-driven concrete technologies.

At the center of this connected ecosystem is Roxi, Giatec’s AI engine. Roxi analyzes plant, transit, and jobsite data to detect variability early and help producers keep optimized mixes optimized over time—turning SmartMix from a data platform into an intelligence layer for consistent, confident ready-mix production optimization.

With this connected architecture in place, producers can:

- Centralize data from plant, transit, and jobsite stages

- Detect variability earlier and respond proactively

- Maintain optimized mix designs over time

- Replace guesswork with insight-driven decisions

- Reduce material costs and carbon impact simultaneously

By creating an ecosystem that integrates technologies and centralizes data, Giatec enables producers to reduce inefficiencies, lower material usage, and improve consistency without compromising performance.

Roxi is trained on over 100M cubic yards of concrete. Learn how it’s making a real impact on the concrete industry!

Want to take the guesswork out of concrete slump?

Plant-to-Pour Visibility: Bringing Concrete Data Into One View

Within the “Plant of the Future” architecture, SmartMix serves as the platform where concrete data from across the lifecycle comes together. Instead of data being scattered across disconnected systems, SmartMix connects the key stages of concrete production and delivery, so teams can track performance from plant to pour, in real-time.

- Plant Data – Establish the Mix Design Intent: At the plant, SmartMix integrates with batching, dispatch, QC, and material systems to capture the data that defines how the concrete was produced. This creates a digital baseline for each load, including mix design intent and production conditions. When paired with plant material technologies such as digitalAggregate, producers can add real-time insight into aggregate gradation, helping identify material variability before it impacts the mix.

- In-Transit Data- Monitor Concrete Quality During Delivery: As the load leaves the plant, SmartMix extends visibility beyond dispatch through in-transit technologies that work together to give teams a more complete delivery picture. MixPilot provides real-time in-transit monitoring of slump, temperature, and volume, helping QC teams and drivers ensure concrete stays in spec during delivery. CiDRA’s SMARThatch adds additional quality signals such as air percentage and return volume readings, along with key drum/load indicators, giving producers even more confidence in quality upon arrival. Digital Fleet strengthens continuity from dispatch to delivery through fleet tracking and logistics visibility, helping connect load performance with delivery execution in one view.

- Pour and Early-Age Data – Validate Performance After Placement: For projects requiring insight beyond delivery, SmartRock® Pro extends the data stream into curing and early-age strength development. As a fully self-calibrating, mix-independent sensor, it provides real-time in-place strength visibility even when mix fluctuations occur.

By bringing plant, transit, and jobsite data into SmartMix, the “Plant of the Future” transforms isolated data into connected insight, enabling producers to manage quality proactively and support more confident ready-mix production optimization from plant to pour.

Turning Data into Confident Decisions

When data from across the concrete lifecycle is brought into a single platform, producers gain a clearer understanding of how mix designs behave from production through placement and early-age curing. Instead of reacting to isolated issues after they occur, teams can see patterns, trends, and deviations as they emerge.

This shift enables ready-mix production optimization to move from periodic adjustments to a continuous, data-informed process. Advanced analytics and AI translate complex inputs into practical guidance, helping producers maintain consistency, manage variability, and make decisions with greater confidence across their operations.

Giatec’s Connected Future for Ready-Mix Operations

The “Plant of the Future” is not a distant vision. It is being built today by connecting the technologies producers already rely on and turning messy, siloed data into a whole picture of concrete performance from plant to pour.

Through the power of SmartMix, Roxi, and technology partnerships, such as alterBiota, CiDRA, Command Alkon, and Climate Earth, Giatec is helping producers move from disconnected workflows to fully connected operations. By integrating systems across production, transit, and placement, producers can reduce inefficiencies, maintain confidence in optimized mixes over time, and make proactive decisions with greater consistency.

The result is smarter ready-mix production optimization that improves environmental performance and profitability, powered by better information, better tools, and greater confidence in every decision from plant to pour.

The journey toward the “Plant of the Future” has now begun! Want to be a part of it? On April 14-16, 2026, we’ll be hosting Giatec’s 3rd Annual Concrete Tech Summit with yet another leading producer, Maschmeyer Concrete. This exclusive event will be located in sunny Orlando, Florida, at the Florida Concrete & Products Association’s HQ, featuring expert-led panels, vendor presentations, a plant tour, and much more. You don’t want to miss this.

RSVP with us to show your interest and be the first to know when official registration opens!

Join Giatec’s 3rd Annual Concrete Tech Summit (April 14-16, 2026)! RSVP today.