CEMEX, S.A.B. de C.V. (“CEMEX”) (NYSE: CX) announced on May 4th 2016 that CEMEX Mexico developed a fire- and explosion-resistant concrete. The company designed this solution specifically to safeguard the Data Processing Center, Proyecto Q, of the Santander Group. Located in Queretaro, Mexico, Proyecto Q is the Santander Group’s most technologically intensive and energy-efficient data processing center in the world.

When a gas station was built 20 meters away from Proyecto Q’s façade, the Santander Group carried out a risk analysis and concluded that its facilities were vulnerable to the effects of potential thermal radiation (fire) and overpressure (explosion). The Santander Group turned to CEMEX for the design and construction of a perimeter wall capable of withstanding both scenarios.

“Only CEMEX, through its Cement and Ready Mix Technology Center, was able to provide us with the perfect solution for this significant challenge,” said David Romero, Real Estate Director in Queretaro for the Santander Group in Mexico.

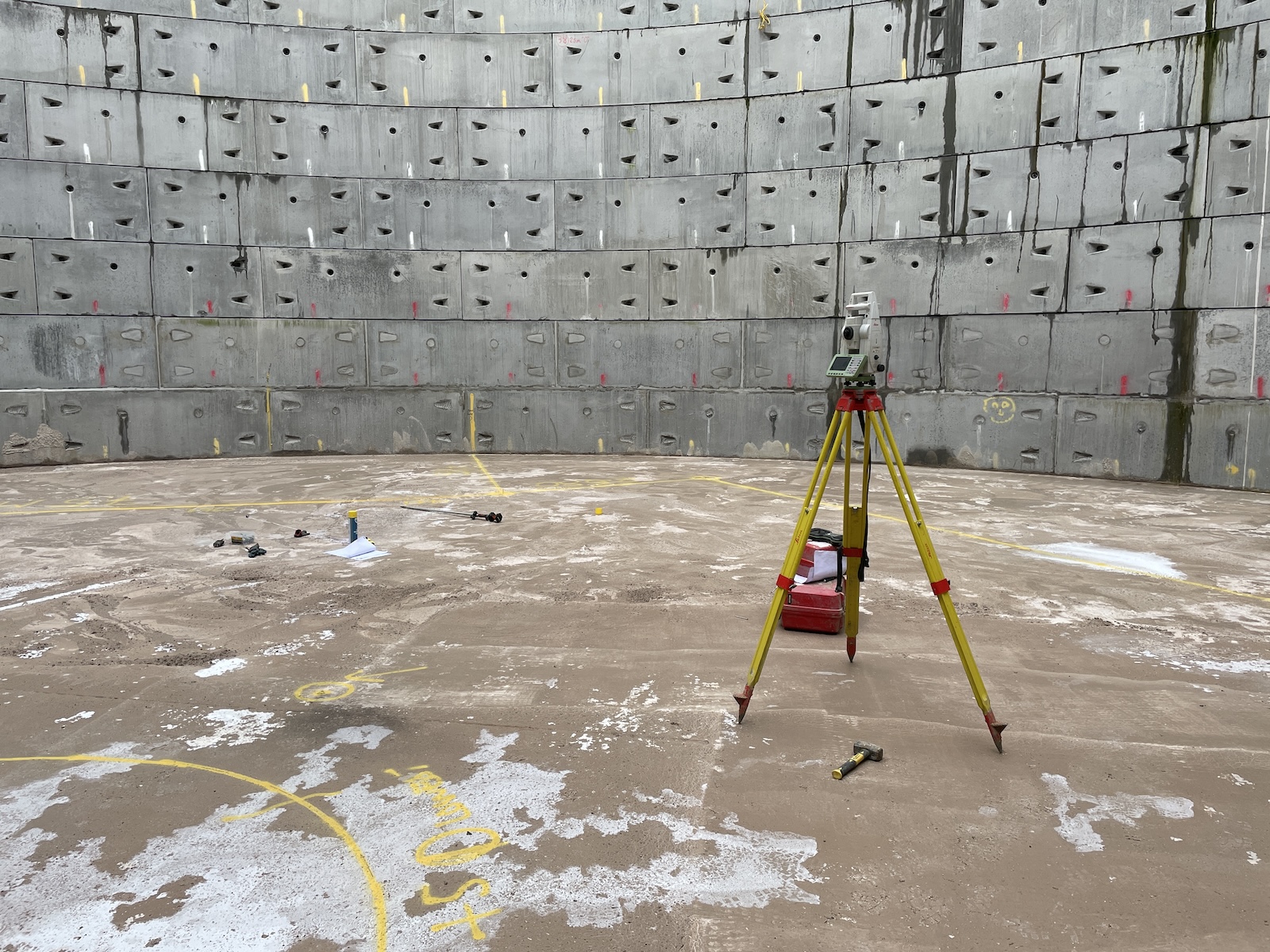

The result developed for the Santander Group is a 204-meter long and 1.10-meter thick perimeter barrier with a maximum height of 10.30 meters. The design is comprised of two 50- and 20-centimeter thick walls, separated by a 40-centimeter wide air chamber. CEMEX in Mexico supplied 3,000 cubic meters of a high-strength structural concrete with special raw materials that increase its fire resistance. Additionally, its durable and curable auto-compacting specifications facilitate the ecological and economic viability of the project.

In order to certify CEMEX’s specialty concrete for the project, a full-scale prototype of the wall was built at the Efectis and TNO research centers in the Netherlands. The wall was subjected to physical fire tests, withstanding a temperature of 1150° C for more than 60 minutes, and to impact tests of a direct overpressure wave of 1.1 bars for 80 milliseconds. The success of these experiments met the demands stipulated in preliminary studies, and the performance of the wall was awarded certification from the Bureau Veritas rating company.

CEMEX’s cement and ready mix technology centers are part of the R&D collaboration network, headed by CEMEX Research Group AG, based in Switzerland.

CEMEX is a global building materials company that provides high quality products and reliable service to customers and communities in more than 50 countries. Celebrating its 110th anniversary, CEMEX has a rich history of improving the well-being of those it serves through innovative building solutions, efficiency advancements, and efforts to promote a sustainable future.

Source: http://www.cemex.com/