Dubai’s Law No. 7 of 2025 has introduced a new contractor classification system that redefines how contractors operate in the emirate.

Move Data Center Projects Faster

Dubai Municipality’s digital registry records and links every aspect of a contractor’s performance to classify them under its new, publicly accessible contractor classification law.

The latest challenge for most contractors lies in maintaining up-to-date quality documentation and real-time compliance records. Dubai Municipality’s digital registry connects every aspect of a contractor’s operational performance, meaning testing delays and documentation gaps can affect classification standing.

According to the AECOM Middle East Review 2025, regional construction projects experience average delays of 83% beyond schedule, with traditional 28-day concrete strength testing remaining a key contributing factor.

In this blog, let’s explore how real-time concrete monitoring using the maturity method helps contractors eliminate testing bottlenecks, maintain schedules, and demonstrate quality control competency under Law No. 7.

Understanding Dubai’s Law No. 7 of 2025

Issued on July 8, 2025, Law No. 7 establishes a unified contractor classification system managed by Dubai Municipality. This new framework represents a complete restructuring of how contractors are evaluated and authorized to operate in Dubai.

Contractors have one year from the law’s effective date (six months after its publication in the Official Gazette) to regularize their status. Dubai Municipality may extend this period to two years in certain cases, though early compliance remains the recommended approach.

The Penalty Structure

The regulation establishes strict requirements for maintaining classification status. Contractors can face penalties of up to Dh200,000, potential downgrades, or even license suspensions for non-compliance. Gulf News outlines a tiered penalty structure under Law No. 7:

- First violation: Dh1,000 to Dh100,000

- Repeat violations: Up to Dh200,000

- Additional penalties:

- Business suspension for up to one year

- Classification downgrades that restrict project eligibility

- Removal from the contractor registry or complete license cancellation

The law also grants designated officials judicial authority to conduct on-site inspections and audits at any stage of a project. These reviews may include assessments of quality control systems, documentation processes, and technical competency.

Digital Registry Integration

The new contractor registry operates through a digital platform connected to the “Invest in Dubai” portal. Classification status, technical records, and compliance history are visible to project owners, consultants, and government agencies across Dubai’s construction ecosystem.

Every project contributes to this record. Testing delays, documentation gaps, or quality issues become part of a contractor’s permanent compliance profile.

Why Traditional Testing Falls Short

Dubai’s new contractor evaluation framework places significant emphasis on technical competency, with quality control serving as a central assessment factor.

The Dubai Building Code requires residential buildings to achieve a minimum concrete strength of 25 MPa, supported by complete test documentation throughout construction. Authorities can request verification tests at any stage to confirm compliance.

However, the traditional methods used to verify concrete strength often struggle to keep pace with these evolving quality and documentation requirements.

Limitations of Traditional Concrete Strength Testing

Traditional concrete strength testing relies on cylinder break tests performed at 7, 14, or 28 days after placement, and in some cases at 56 days for mixes with high cement replacements. These extended testing timelines often cause project delays.

Incorporating third-party lab testing introduces further complexity; human error, sample transport, test coordination, result turnaround, and potential re-tests can all delay critical milestones. For example, if formwork removal is scheduled for day five but test results are not available until day seven, the project faces a difficult decision: delay progress or proceed without verification.

Impact on Classification Status

Testing delays can directly affect contractor classification. Operating beyond approved technical capacity, incomplete documentation, or recurring project delays can trigger penalties and downgrades. Each missed milestone may signal deficiencies in technical competency, which is central to classification assessments.

Maintaining a proactive, systematic approach to quality control is therefore essential. Traditional testing methods make this increasingly challenging.

Want to learn more about building standards? Check out our blog on SASO!

Meeting Dubai’s Construction Demands with Real-Time Monitoring

To overcome these challenges, many contractors around the world are adopting innovative concrete monitoring systems that provide faster, more accurate strength insights directly on site.

Real-time concrete monitoring using the maturity method is a well-established, standardized approach supported by decades of research and implementation.

The maturity method follows the Gulf Standard GSO ASTM C1074:2024 and is referenced in ACI 318, AASHTO T 325, CSA A23.1, and numerous DOT specifications worldwide. It calculates a maturity index based on the temperature-time history of concrete, which correlates directly to strength development.

Continuous temperature monitoring from placement through curing enables accurate, real-time strength estimation without waiting for lab results. This method provides data based on actual in-place curing conditions rather than idealized lab environments, improving accuracy in Dubai’s variable climate.

Don’t let hot weather impact your construction project timeline. Learn how the maturity method can help!

Implementing Real-Time Monitoring with SmartRock™

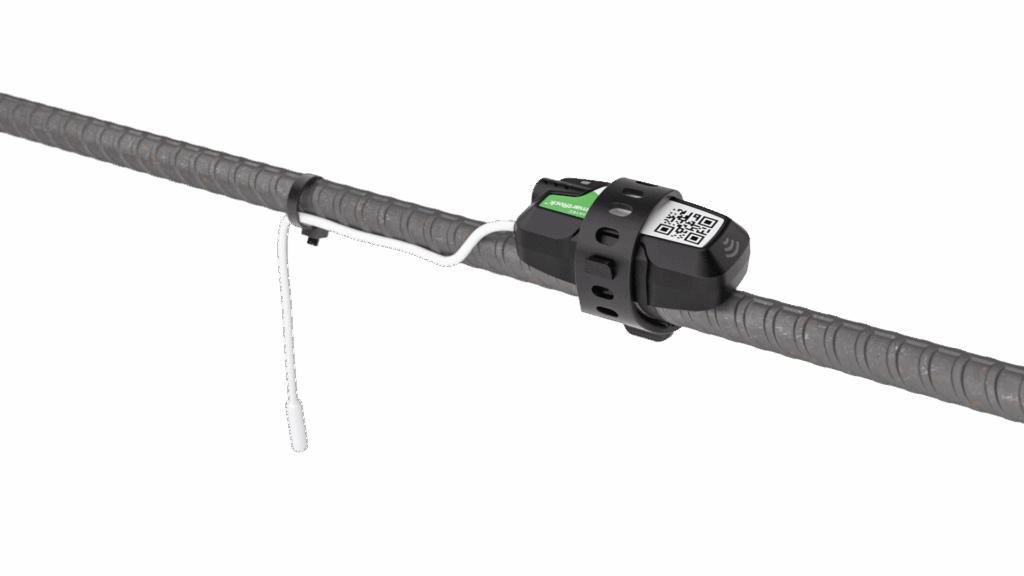

Designed to measure real-time concrete temperature and strength, SmartRock wireless sensors (based on ASTM C1074) bring the maturity method from laboratory research to practical field application. The fully embedded sensors are installed directly on the rebar before pouring and remain in place throughout curing, eliminating the need for external wires or repeated handling. With real-time data and remote monitoring capabilities, contractors can confidently check the status of each pour and receive notifications anytime, anywhere, on any device.

As of 2025, three versions are available to address different project requirements:

- SmartRock provides dual temperature monitoring with 15-minute updates and a communication range of up to 12 meters when positioned near the concrete surface, making it suitable for most standard projects.

- SmartRock Long Range extends communication up to 300 m (1,000 ft), ideal for large-scale developments such as high-rises and infrastructure projects in Dubai where extended connectivity is essential.

- SmartRock Pro is the first fully self-calibrating concrete strength sensor using CEMMA technology. It mounts directly onto rebar and enables mix-independent monitoring. Unlike traditional maturity sensors requiring pre-pour calibration for each mix design, SmartRock Pro eliminates that step, reducing pre-construction testing and simplifying quality control for complex projects involving multiple concrete mixes. At this time, it is only available in North America.

Each iteration of SmartRock is designed to deliver accurate, real-time insights that enhance decision-making and ensure consistent performance across diverse construction environments.

Integrating Real-Time Data into Dubai’s Compliance Framework

Beyond monitoring performance, SmartRock simplifies how contractors document and verify compliance under Dubai’s Law No. 7.

The data collected remains securely stored within the contractor’s account, fully private and accessible only to authorized project personnel until they choose to share or report.

SmartRock connects to the Giatec 360™ cloud dashboard for centralized data management. Every monitored pour generates a digital audit trail of temperature and strength development, complete with timestamps and location references. Reports can be exported in formats recognized by Dubai Municipality and accredited third-party labs.

This documentation supports both organizational quality systems and individual technical competency certifications, aligning with Dubai’s contractor classification requirements.

Build better with excellent documentation. Download our Guide to Construction Documentation Management!

A Real-World SmartRock Case Study in the Gulf Region

FCC Construcción led a joint venture (with CSCEC and Shibh Al-Jazira) on THE LINE tunneling construction project within NEOM, one of the Middle East’s largest infrastructure projects.

Prior to adopting SmartRock, the team relied on standard lab-cured cylinders for strength verification, which caused delays and limited insight into real-time performance. SmartRock sensors enabled continuous monitoring of temperature differentials, maturity, and compressive strength from the first day of curing.

The results included improved formwork removal timing, faster strength development compared to lab-cured samples, and shorter schedules. Through real-time decision-making, and measurable cost savings from reduced delays, the team enhanced their overall productivity. Now that’s a SmartRock success!

These outcomes demonstrate how maturity-based monitoring directly addresses the same challenges Dubai contractors face under Law No. 7.

Move Data Center Projects Faster

Benefits of Real-Time Monitoring for Contractor Classification

Real-time concrete monitoring supports the core objectives of Dubai’s new contractor evaluation framework.

- Systematic Quality Control: Continuous monitoring demonstrates proactive verification rather than reactive testing.

- Digital Documentation: Timestamped data creates a verifiable audit trail compatible with Dubai’s contractor registry.

- Schedule Adherence: Eliminating testing bottlenecks supports improved delivery timelines and operational records.

- Professional Development: Using ASTM C1074 methodology strengthens technical competency and certification renewal.

- Risk Mitigation: Real-time alerts allow early intervention before issues escalate.

- Cost Control: Avoid penalties, maintain schedules, and protect both profitability and classification status.

With SmartRock, contractors can achieve these benefits through automated monitoring that delivers ASTM C1074-compliant data directly from the jobsite. Together, these capabilities help contractors demonstrate technical competency, ensure continuous compliance with Dubai Municipality standards, and strengthen their long-term classification standing.

Implementation Roadmap for Concrete Monitoring Success

A structured implementation plan is the best way to integrate real-time concrete monitoring effectively and ensure alignment with Dubai Municipality’s compliance standards.

The table below outlines a practical example of how contractors can implement monitoring technology from initial assessment to full documentation integration.

| Phase | Timeline | Key Actions |

| 1. Assessment | Weeks 1-2 | Review current testing protocols against Dubai Municipality Technical Guide requirements. Identify high-risk projects and determine ASTM C1074 training needs. |

| 2. Pilot Deployment | Weeks 3-6 | Deploy SmartRock sensors on selected pours, such as post-tensioned slabs or structural elements with tight schedules. Document procedures and train key personnel. |

| 3. Standard Protocol Development | Weeks 7-10 | Establish deployment standards for critical structural elements, post-tensioned systems, or fast-track activities based on pilot results. |

| 4. Documentation Integration | Weeks 11-12 | Integrate sensor data into project quality management systems for seamless Dubai Municipality inspection workflows. |

Critical dates to remember:

- Late 2025: Law No. 7 becomes effective.

- Late 2026: One-year grace period ends.

Starting this process early allows contractors to establish consistent monitoring practices, streamline compliance documentation, and avoid last-minute challenges as Law No. 7 enforcement approaches.

Conclusion

Law No. 7 of 2025 has transformed Dubai’s contractor landscape. Quality control is now directly tied to classification and licensing.

Traditional concrete testing often creates conflicts between maintaining compliance and meeting schedules. Real-time monitoring with SmartRock resolves this by providing continuous, verifiable data that supports both operational efficiency and regulatory compliance.

With penalties reaching Dh200,000 and license suspensions possible, proactive compliance is essential. SmartRock enables contractors to meet documentation, performance, and quality verification standards efficiently and transparently.

Interested in learning more about compliance and concrete standards in Saudi Arabia? Explore our resources in the Saudi Arabia region!

Sources

Law No. 7 of 2025 on Contracting Activities in Dubai

Gulf News: New Legal Framework for Dubai’s Contracting Industry

ASTM C1074: Standard Practice for Estimating Concrete Strength by the Maturity Method

ACI 207: Guide to Mass Concrete